Single girder cranes (single beam crane) are usually used for light or medium-sized services in workshops, warehouses, storage yards, etc. The crane has two main configurations, including top running and suspension system. According to your specific lifting requirements and facility conditions, we will design the most appropriate bridge crane system to maximize your work efficiency and safety.

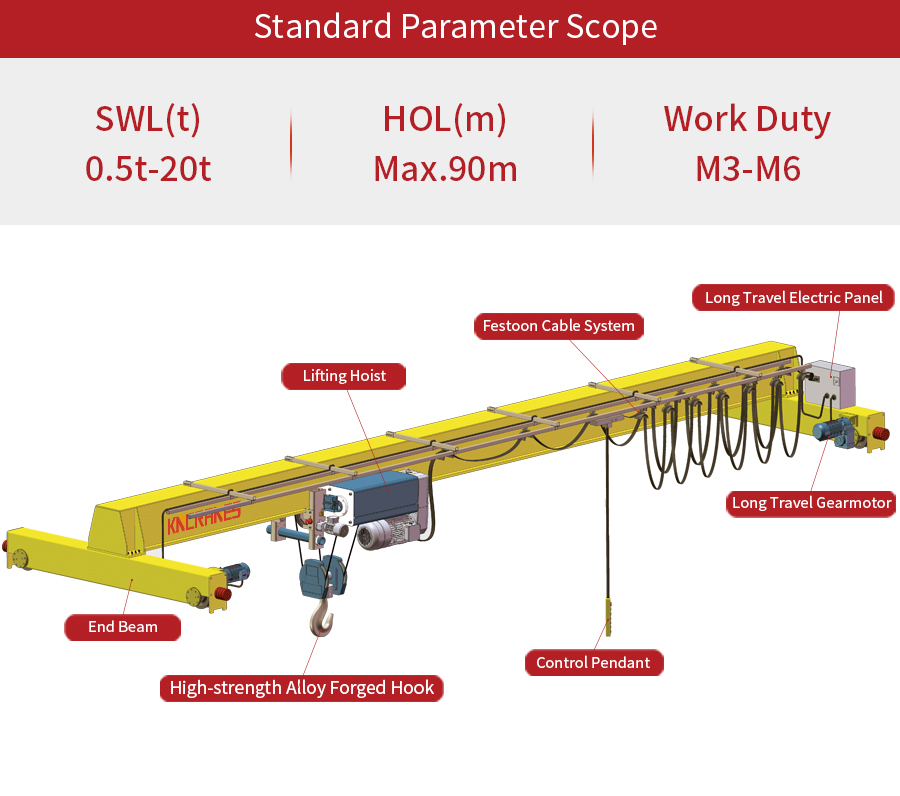

The construction of a single girder crane consists of a single girder beam, known as a bridge, that runs the building’s width. A trolley moves horizontally along the bridge, positioning a hoist and hook, which is used to raise or lower the load.

Three control methods of single girder cranes:

1.Pendent control: A. Easy operation when obervation. B. Convenient to communication with other workers.

2.Wireless remote control: A. Greatly improved the work efficiency. B. Keep the operator from danger.

3.Cabin room control.

Features

Single Girder Crane Classifications

At Sinoko Cranes, we offer our customers six unique single girder crane designs to meet their specific needs.

Single Girder Crane Design

Although the single girder crane is limited in capacity and span, its design has many advantages and is an ideal solution for many applications.

They can be integrated into the building design to save the cost of runway structure. The hoist trolley can go underneath the runway, providing the best end approach, and the low headroom design, especially with notched bridge beams, takes advantage of the runway depth.

Single girder cranes are one of the most cost-effective lifting solutions because they are easier to install and maintain. Because they only need one bridge, they are more compact and lighter than double beam cranes, saving materials, freight, installation and maintenance costs.

Specification

| Capacity | 1~20 tons |

| Lift height | Max. 90 m |

| Span | 7.5~40m |

| Work duty | M3~M6 |

| Protection class | IP54/IP55 |

| Working temperature | -20~+60℃ |

CASE

Want to see how our remote-controlled, SEW motor-driven overhead cranes are used in actual projects? Explore our crane case studies to learn how we’ve delivered reliable, efficient lifting solutions across various industries and operational environments.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

Equipped with SEW motor technology and wireless remote control, this crane offers precise operation, enhanced operator safety by distancing them from the load, and streamlined workflows—making it an efficient and secure solution for diverse industrial environments.

Thanks to its lightweight, single-girder design featuring low headroom and minimized hook-to-wall clearance, it’s ideal for light to medium-duty applications across workshops, warehouses, and manufacturing facilities—especially in buildings with limited vertical space or narrower spans.

Designed for capacities ranging 1–20 tons, this single-girder model delivers impressive lift heights (up to around 90 m), spans from roughly 7.5–40 m, and reliable duty cycles in the range of M3–M6—ensuring strong performance across various lifting demands.

The single-girder structure needs fewer materials, is lighter in weight, and simplifies installation—translating to lower investment, freight, and maintenance costs when compared to double-girder alternatives.

Operators can choose from pendant (corded), wireless remote, or cabin control modes, giving flexibility to adapt to safety requirements, site conditions, or operator preference—enhancing usability and control over crane movements.

Built to operate across a wide temperature range (as low as –20 °C to +60 °C) and equipped with robust protection (IP54/IP55), this crane ensures durable, high-performance operation in demanding industrial settings.