Overview

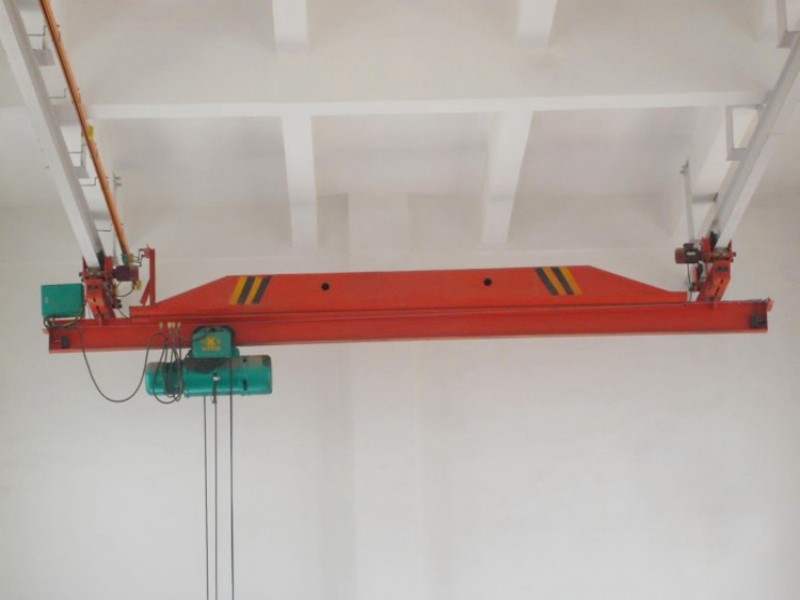

The LX Under Running Crane is a suspension overhead crane developed as an enhancement of the LD model. It boasts a more structurally sound design and utilizes higher-strength steel, contributing to its overall durability.

The LX model is typically paired with CD1/MD1/HC model wire rope electric hoists or electric chain hoists, forming a complete set. This combination positions the LX crane as an ideal solution for light-duty track travelling, especially in environments such as machinery assembly sites and warehouses.

Features

The Single Girder Underslung Crane, such as the LX model, is specifically designed for situations where a top running bridge crane structure is not feasible. This design allows for efficient use of space, especially in places where overhead clearance is limited.

Optimized End Beams Design: The end beams of the LX crane are carefully designed to ensure optimal load distribution. These can be made from rigid beam or welded box beam, which helps to distribute the weight of the load more evenly, reducing stress on any one part of the structure.

Tailored Beam Ends: One of the standout features of the LX crane is its tailored beam ends. These beam ends can be custom-designed to suit specific application requirements, allowing for effective material handling even near the building walls. This design feature maximizes the operational space, ensuring that the crane can operate efficiently in a variety of settings.

These design elements make the Single Girder Underslung Crane an ideal solution for situations where conventional crane structures cannot be implemented. The standardized design of the LX crane ensures that lifting height is effectively utilized, providing a reliable, efficient, and space-saving solution for various material handling needs.

Specification

Lifting Capacity (ton) | 0.5 ton, 1 ton, 2 ton, 3 ton, 5 ton, 10 ton | |||

Span (meter) | 3-16 | |||

Crane Travelling Mechanism | Travelling Speed (m/min) | 20/30 | ||

Motor | 0.5- 3 ton | ZDY12-4; N = 2x0.4kw | ||

5- 10 ton | ZDY21-4; N= 2x0.8kw | |||

Lifting Mechanism | Electric Hoist | Lifting Speed (m/min) | 8; 0.8/8 | |

Lifting height (meter) | 6 -30m | |||

Trolley Device | Trolley Traverse speed (m/min) | 20/30 | ||

Motor | Taper Brake Rotor Motor | |||

Working Duty | M3/A3 ( 25% ) | |||

Power Supply | 3 Phase; 380V/50HZ | |||

Wheel Diameter | 0.5 -3 ton | 134 mm | ||

5 -10 ton | 154 mm | |||

Recommend Travel I beam | 0.5 - 2 ton | 20a- 45c | ||

3-5 ton | 32a - 45c | |||

10 ton | 40b - 63c | |||

CASE

Browse more crane project cases to see how Sinoko solutions are applied across various industries and work environments.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

This model accommodates capacities from 0.5 up to 10 tons, with spans ranging between 3 m and 16 m. It’s ideal for light-duty applications in machinery shops and warehouses.

The crane pairs with CD1/MD1 wire rope electric hoists or alternative electric chain hoists as a complete lifting solution.

Unlike traditional top‑running cranes, this design is suspended from overhead roof beams, freeing up floor space and maximizing headroom in workshops with limited vertical clearance.

The LX crane runs on 380 V/50 Hz three-phase power and has a working duty rated as A3, making it suitable for light-to-moderate workload environments.

It features travelling speeds of 20–30 m/min for both crane and trolley, with lifting speeds around 8 m/min (or dual-speed options like 0.8/8 m/min), offering smooth and efficient operation.

The end beams—either rigid or welded box types—are designed for optimal load distribution. Beam ends can also be custom-tailored to allow operations close to building walls, improving space efficiency and versatility.