Overview

Heavy duty barrel winch trolley type of DG EOT Crane are designed and manufactured to customer’s precise needs.

Heavy Duty DG EOT Crane will have two bridge beams, and the heavy duty open winch trolley travels on rails, attached to the tops of the crane girder.

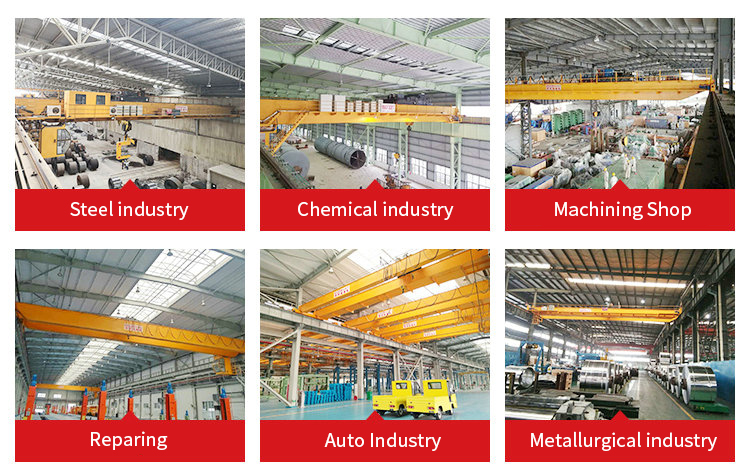

Double girder EOT crane applied in power plant, workshop duty, transformer industry, cable industry, process plants, steel plants, coal fields, cement plants, engineering industry.

Hot Models of Heavy Duty DG EOT Crane

Sinoko Crane designs different cranes according to the needs of the heavy industry, such as electromagnetic overhead crane, grab overhead cranes, Ladle Crane and coil handling overhead crane, etc.

Our company is a reputable crane manufacturer, which devotes to the design and produce of heavy duty crane for many years. Products of our group are sold all over the world. Our customers come from oversea including American, African, and South American, etc. please feel free to contact us if you have any problem.

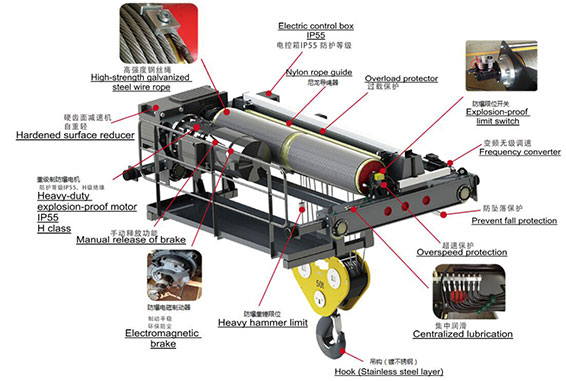

Features

1. Smooth starting and braking

2. Low noise, commodious cabin and good view

3. Convenient maintenance, excellent exchange ability for components

4. Energy saving,reduce energy consumption

Special Features of Heavy Duty Open Winch Trolley

Specification

| Capacity(kg) | Span(m) | Lifting Height(m) | Lifting speed(m/min) |

| 5000 | 10.5 | 9 | 5/0.83 Double speed |

| 13.5 | |||

| 16.5 | |||

| 19.5 | |||

| 22.5 | |||

| 25.5 | |||

| 28.5 | |||

| 31.5 | |||

| 10000 | 10.5 | 9 | 5/0.83 Double speed |

| 13.5 | |||

| 16.5 | |||

| 19.5 | |||

| 22.5 | |||

| 25.5 | |||

| 28.5 | |||

| 31.5 | |||

| 16000 | 10.5 | 10 | 5/0.83 Double speed |

| 13.5 | |||

| 16.5 | |||

| 19.5 | |||

| 22.5 | |||

| 25.5 | |||

| 28.5 | |||

| 31.5 | |||

| 20000 | 10.5 | 10 | 5/0.83 Double speed |

| 13.5 | |||

| 16.5 | |||

| 19.5 | |||

| 22.5 | |||

| 25.5 | |||

| 28.5 | |||

| 31.5 | |||

| 25000 | 10.5 | 10 | 5/0.83 Double speed |

| 13.5 | |||

| 16.5 | |||

| 19.5 | |||

| 22.5 | |||

| 25.5 | |||

| 28.5 | |||

| 31.5 | |||

| 32000 | 10.5 | 9 | 4/0.67 Double speed |

| 13.5 | |||

| 16.5 | |||

| 19.5 | |||

| 22.5 | |||

| 25.5 | |||

| 28.5 | |||

| 31.5 | |||

| 40000 | 10.5 | 9 | 3.2/0.5 Double speed |

| 13.5 | |||

| 16.5 | |||

| 19.5 | |||

| 22.5 | |||

| 25.5 | |||

| 28.5 | |||

| 31.5 | |||

| 50000 | 10.5 | 9 | 2.5/0.4 Double speed |

| 13.5 | |||

| 16.5 | |||

| 19.5 | |||

| 22.5 | |||

| 25.5 | |||

| 28.5 | |||

| 31.5 | |||

| 63000 | 10.5 | 9 | 2.5/0.4 Double speed |

| 13.5 | |||

| 16.5 | |||

| 19.5 | |||

| 22.5 | |||

| 25.5 | |||

| 28.5 | |||

| 31.5 | |||

| 80000 | 10.5 | 9 | 2/0.3 Double speed |

| 13.5 | |||

| 16.5 | |||

| 19.5 | |||

| 22.5 | |||

| 25.5 | |||

| 28.5 | |||

| 31.5 |

CASE

See how our overhead crane systems perform in real-world environments. From heavy-duty lifting in steel mills to custom handling in power plants, explore project cases that showcase our engineering expertise and commitment to reliable, efficient crane solutions.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

This heavy-duty crane—ideal for loads exceeding 10 t and spans over 25 m—is widely used in industries such as power plants, workshops, transformers, cable manufacturing, steel mills, coal fields, cement works, and general engineering projects.

The crane features safe working loads (SWL) ranging from 5 t to an impressive 80 t (and up to 500 t for custom designs), with lifting heights as high as 160 m—demonstrating the flexibility designed for demanding heavy‑load scenarios.

Key advantages include smooth starting and braking, low operational noise, a spacious and well‑positioned operator cabin, easy maintenance access, highly interchangeable components, and energy‑saving design that reduces power consumption.

Sinoko guarantees all variants of the double‑girder EOT crane retain maximum structural rigidity while minimizing dead weight—ensuring exceptional load support without unnecessary bulk.

It employs a heavy‑duty open‑winch trolley mounted on rails atop the two bridge girders—offering durable and high‑precision load handling tailored to the customer’s unique application needs.

Absolutely—Sinoko designs these cranes precisely to client requirements, offering various types such as electromagnetic overhead cranes, grab cranes, ladle cranes, and coil‑handling cranes, all with consistent high performance and quality.