Overview:

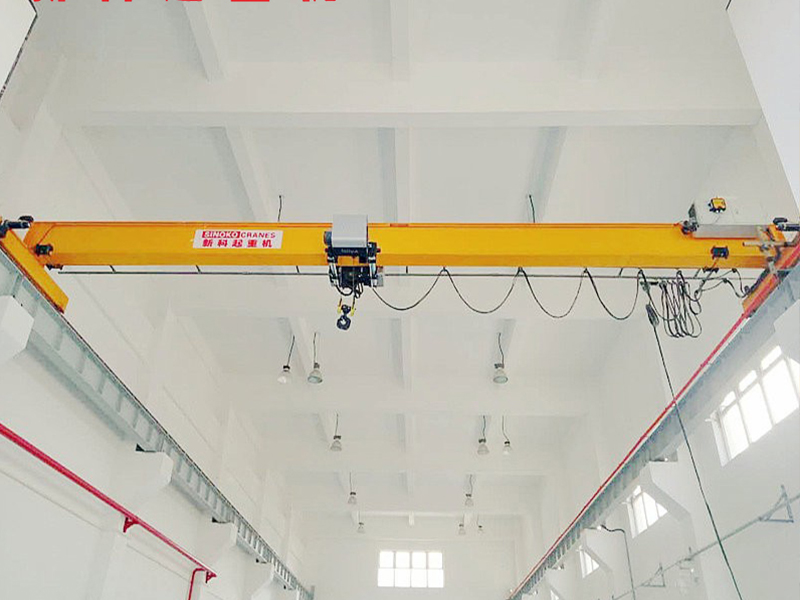

The FEM standard monorail overhead crane is a small light crane with single beam running with electric hoist. This product is widely used in mechanical manufacturing, warehousing, assembly, material yard and other places for loading and unloading and transporting objects. It is strictly prohibited to use and hoist molten metal in flammable, explosive corrosive medium.

With the key parts of European Hoist, our Roof Traveling Bridge Crane could run smoothly, durable, variable speed, light weight, smart structure.

Features

Due to the unique design referring to European FEM standard, this type of overhead crane has the advantages as bellow:

1. Compact structure, small size, light weight and beautiful appearance, It achieves material handling in three-dimensional space;

Compared with the

traditional crane, it has the minimum distance limit for hook to the wall, minimum headroom, more close to operations, higher lifting height, which actually increases the factory effective work space.

For the new factory it could be designed smaller and more functional.

2. Low energy consumption, small wheel pressure ,reasonable load.

It means that a considerable amount of money can be saved for long-term heating, air conditioning, and other maintenance costs in initial construction.

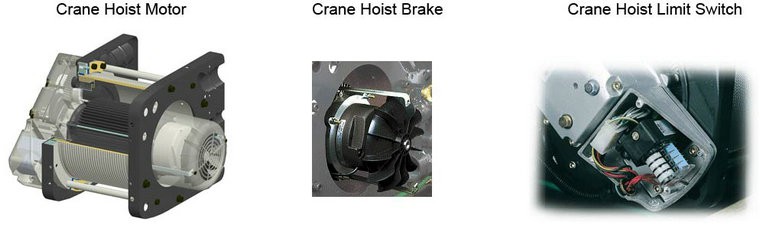

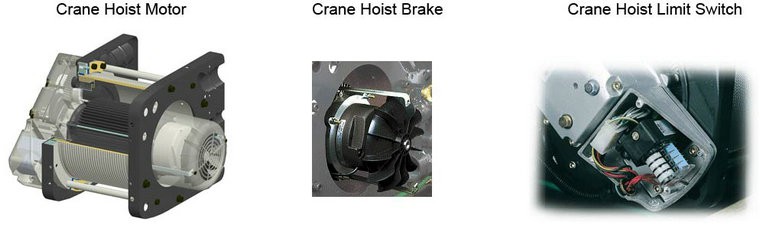

1. Mechanical parts

(1) Single main beam, welded box, the arch in line with national standards.

(2) The steel sheet material is Q235B or Q345B.

(3) The web plate is cut by 40m CNC machine cutting to ensure smooth molding and precision of the crown curve.

(4) The main weld with submerged arc welding, non-destructive testing.

(5) After welding the whole beam shot blasting treatment, to Sa2.5 level, to eliminate welding stress.

(6) Epoxy zinc-rich paint, two bottom two sides, 140μ thick, long life, beautiful appearance, good gloss.

(7) The main beam and the end beam are connected with 10.9 high strength bolts to ensure the strength and precision of the whole structure.

(8) The long travelling and trolley are all use three-in-one drive mechanism, variable frequency stepless speed, hardened surface, disc brakes.

(9) Long travelling level IP55, F-class insulation, power transfer rate of 40% ED.

(10) End beam configuration flat wheel or double wheel rim wheel, anti-wear bearing, cart buffer block, anti-derailment end plate.

2. Electric Parts

(1)Long travelling, cross travelling and lifting hoist are Independent operation, can run alone or at the same time.

(2) Electronic control box anti-corrosion, protection class to IP55.

(3) All connections are reloaded with aviation plugs and sockets, sealed and fastened

(4) Control box layout reasonable, easy to repair

(5) Plug connection with plastic casing insulation protection

(6) All cables have a line number for easy identification

(7) Trolley mobile power supply system uses crane dedicated PVC flat cable, pressure rating of 450 / 750V

(8) Trolley mobile power supply system by the flat cable, galvanized slide and cable pulley, sliding smooth.

3. Safety Protection System

(1) Long travelling, trolley triple motor anti-fall protection, to prevent accidental fall.

(2) Rain cover: outdoor crane configuration hoisting mechanism, electric control box and drive mechanism of the rain cover

(3)Sound and light alarm device

(4) Wireless collision avoidance device

4. Crane control mode

Pendent line control and remote control

Kindly please provide the following information when sending enquiry to us.

Specification

Load capacity | ( ) | Tips:1t 2t 3t 5t 10t 15t 20t |

Span | ( ) | Tips:7.5m-31.5m |

Lift height | ( ) |

|

voltage | ( ) | 380V 50Hz AC 3-phase or please note |

Working Class | ( ) | Tips: A5 if you don't know, please not |

Hours per day | ( ) |

|

Control way | ( ) | Tips: remote control, cabin control or pendent control |

Get a Free Quote

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More

Get a Quote

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More

Get a Quote

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More

Get a Quote

FAQs

Q: How much workshop space can be saved vs traditional overhead cranes?

A: 40% more vertical space utilization with only 200mm headroom clearance and 300mm minimum hook-to-wall distance. Ideal for low-ceiling workshops.

Q: What's the maximum capacity for roof-mounted installation?

A: 20-ton capacity using Q345B steel beams with CNC-cut camber curves. Structural bolts (10.9 grade) ensure roof safety.

Q: Can it operate outdoors in harsh conditions?

A: Yes - IP55-rated components with rain covers, dust-proof control boxes, and zinc-plated cable slides for corrosion resistance.

Q: What safety features prevent load drops?

A: Triple protection: motor anti-fall brakes, wireless collision sensors, and dual-redundant limit switches. Includes audible/visual alarms.

Q: How does the European FEM standard benefit operations?

A: 35% energy savings via three-in-one VFD drives, hardened wheels, and epoxy-coated steel (140μm thickness) for longevity.

Q: What control options are available?

A: Pendant, remote, or cabin control. All wiring uses aviation plugs and numbered PVC cables (450/750V rated) for easy maintenance.