Overview

Coil handling overhead cranes are specialized cranes designed for the handling of steel coils in industrial environments. These cranes are used primarily in steel mills, coil storage facilities, and other industrial settings where steel coils need to be moved, stored, or transported.

The primary purpose of coil handling overhead cranes is to lift and transport steel coils of varying sizes and weights. These cranes are typically equipped with specialized lifting devices such as C-hooks or lifting magnets that are designed to securely grasp and lift steel coils.

Coil handling overhead cranes are also designed to operate in tight spaces and with high precision, making them ideal for use in environments where space is limited or where precision is required.

Smart coil lifting overhead crane is made for coil plant or storage use. Overhead crane scheduling should have functions of automatic control, location reservation, coordination linkageof multiple crane, safety path planning, collision avoidance control and scheduling optimization.

Features

Crane automatic control Position control:

Technical requirement of Smart control system:

Distinguish | Product Name | Unit | Qty. |

EOT Crane | Crane LAN PC | set | 1 |

Crane Control PLC I/O Module | set | 1 | |

Measuring coil height encoder(Encoder) | set | 1 | |

Laser range finder to measure cross-line distance | set | 1 | |

Laser distance measuring instrument to measure distance | set | 1 | |

Angle measurement sensor | set | 1 | |

Vehicle shape recognition | Laser scanner | set | 1 |

Laser pen | set | 1 | |

Net | Wireless communication device(AP) | set | 1 |

Photoelectric converter (Fiberoptic Converter) | set | 1 |

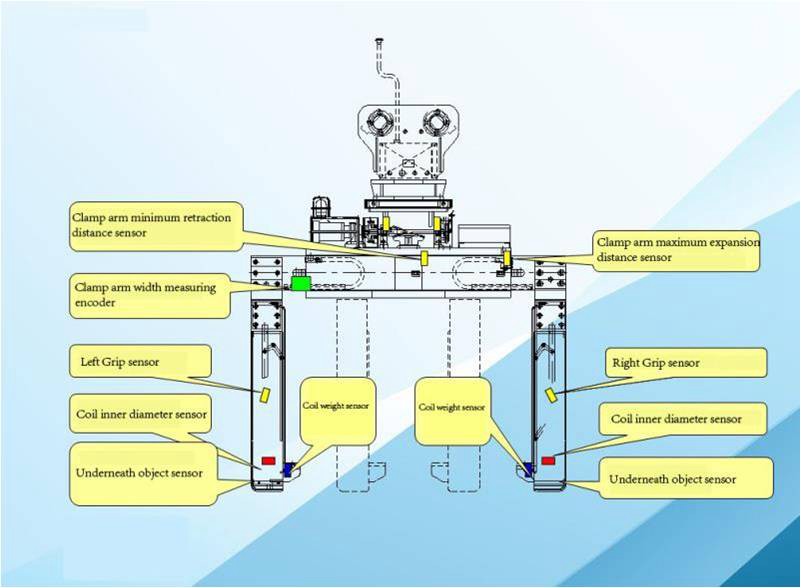

Clamp technical requirements :

The clamp should have the functions of automatic ranging and automatic control, sensing, communication etc., It can automatically run in stable working environment under the existing warehouse. Through identifying instructions issued by the system and combining with automatic decision logic, the clamp can achieve accurate opening, closing, Turning claw movements under the condition that coils will not be damaged and overall work efficiency not be affected.

Specification

PCL control coil lifting overhead crane genaral specifications:

Specifications | 25-30T | |||

Working site | Coil shed | |||

Span (m) | 15-35m | |||

Rail top height (m) | 10 | 10 | 10 | |

Work duty | M6-M8 | |||

Lifting Height | 11m | 11m | 11m | |

Rail type | QU 80 | QU 80 | QU 80 | |

Cabin position | End of span, parallel with main Frame | End of spanparallel with main Frame | End of span, parallel with main Frame | |

Control mode | Cabin Control | Cabin Control | Cabin Control | |

Power Supply | Busbar | Busbar | Busbar | |

Buffer Height mm | ||||

The main lift speed m/min | 0.12 ~12 | |||

Cross traveling speed m/min | 4 ~ 40 | |||

Long traveling speed M/min | 6 ~ 60 | |||

CASE

Want to see how our smart overhead cranes perform in real operations? Explore project case studies that showcase Sinoko Crane’s advanced solutions in coil handling and automated lifting. Discover how we deliver precision, safety, and efficiency across various industrial applications.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

PLC-based vertical and horizontal position control ensures precise coil placement—with positioning accuracy within ±10 mm for the trolley and ±25 mm for cart movement. Advanced anti-sway control further improves coil stability and safety.

This crane comes with smart functions like automatic path planning, collision avoidance, multi-crane coordination, location reservation, and safe zone scheduling, enabling efficient, accurate, and collision-free operations in coil handling facilities.

Key components include PLC I/O modules, encoders for height measurement, laser range finders, angle sensors, laser scanners for object recognition, wireless communication devices, and fiber-optic converters—ensuring responsive, data-driven crane control.

Standard performance specs include lifting up to 25–30 t, spans of 15 m–35 m, lifting heights around 11 m, and operating duties of M6 to M8—ideal for heavy industrial coil handling environments.

Standard performance specs include lifting up to 25–30 t, spans of 15 m–35 m, lifting heights around 11 m, and operating duties of M6 to M8—ideal for heavy industrial coil handling environments.

Tailored for steel mills, coil storage yards, and rolling plants, this overhead crane ensures safe, precise, and efficient coil loading, transport, and storage—especially where automation and high-speed workflows are prioritized.