Overview

Power plant overhead cranes are usually installed in the main engine plant of power plants for the installation and maintenance of generator sets, and the lifting and handling of electrical equipment and other items. The European double-girder crane is usually selected for the main engine plant of the power plant, which has the advantages of small clearance, compact structure, safety and reliability, and firm use.

The scale of operation of thermal power plants is generally relatively large, and the extensive application of cranes in the remanufacturing process has greatly improved the production efficiency. However, the safety of the crane and the safety incidents it brings cannot be ignored.

Features

1. Save working space: Smaller left and right space restrictions, increase working space. The space above the track/track is small, and the workshop space can be fully utilized.

2. Low cost of service and maintenance: reliable performance, durable, reduce extra cost. High quality and performance components require less maintenance and repairs. Lower energy consumption.

3. High performance: The frequency conversion technology is adopted to reduce the working load and make the crane run at high speed under light load. The speed range of 1:10 ensures that the crane runs smoothly and reduces the impact on the workshop. Adopt anti-shake technology to achieve precise positioning.

Specification

(f) Trolley rail: QU100; Crane Wheel: Qu120;

(g) Wheel pressure: trolley 530kn; Crane 300kn;

CASE

In the following section, we invite you to explore several compelling crane project examples that highlight the adaptability, engineering excellence, and performance of our systems. Whether it’s tackling heavy-duty construction, streamlining industrial workflows, or operating in challenging environments, these case studies demonstrate how our solutions rise to diverse real‑world demands—offering insight and inspiration for your next project.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

Sinoko’s cranes are specifically engineered to withstand high-temperature, acidic, corrosive, and potentially explosive conditions inside thermal power plants—thanks to their robust European-style design, durable components, and emphasized safety features.

These European double-girder cranes feature compact structure and minimal clearance requirements, which maximizes workshop space. Plus, thanks to high-quality performance components and reliable frequency‑conversion technology, maintenance and energy costs are significantly reduced.

Absolutely. Sinoko’s cranes support heavy load operations like lifting stators, turbine rotors, and generator equipment, while precision-driven features—such as VFD (variable frequency drive), PLC control, and anti‑shake technology—ensure smooth, accurate positioning.

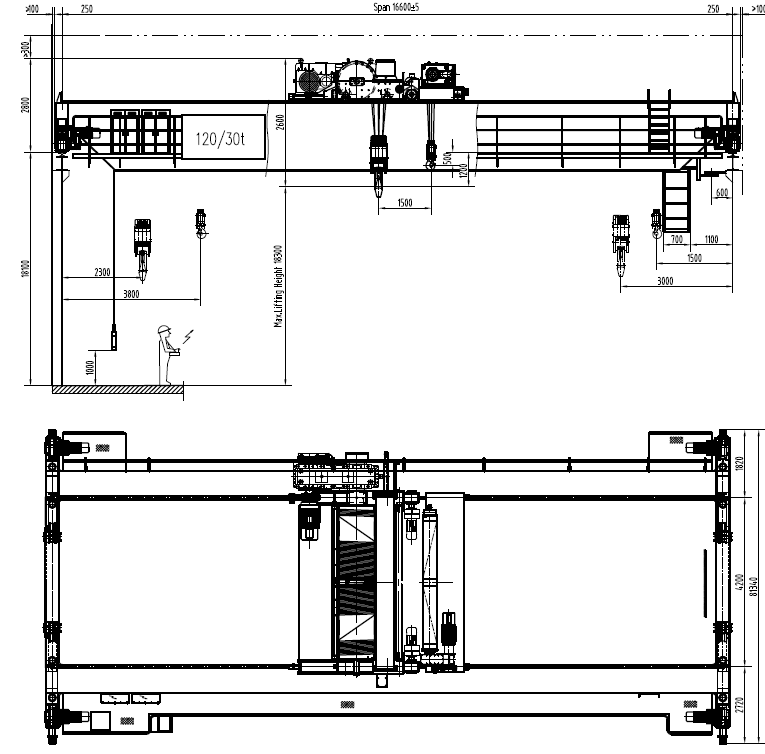

A typical configuration offers a main lifting capacity of 120 tons and auxiliary 30 tons, with 20 m span and 18 m lifting height. It uses Schneider and Siemens controls (VFD and PLC), SEW geared motors. Lifting speeds range from 0.25–2.5 m/min (main), 0.5–5 m/min (aux), with trolley and crane travel speeds up to 32 m/min.

Safety is built in: the cranes are designed for low-frequency, heavy-duty use, minimizing wear from frequent cycles. The structural design and high-quality manufacturing reduce risks in corrosive, flammable, or explosive environments often found in thermal power plants.

Yes. Sinoko offers customization in crane design, control systems, and component selection, allowing clients to tailor the crane to their exact lifting capacity, speed, space restrictions, and safety needs—ensuring optimal integration into each thermal power facility.