Overview

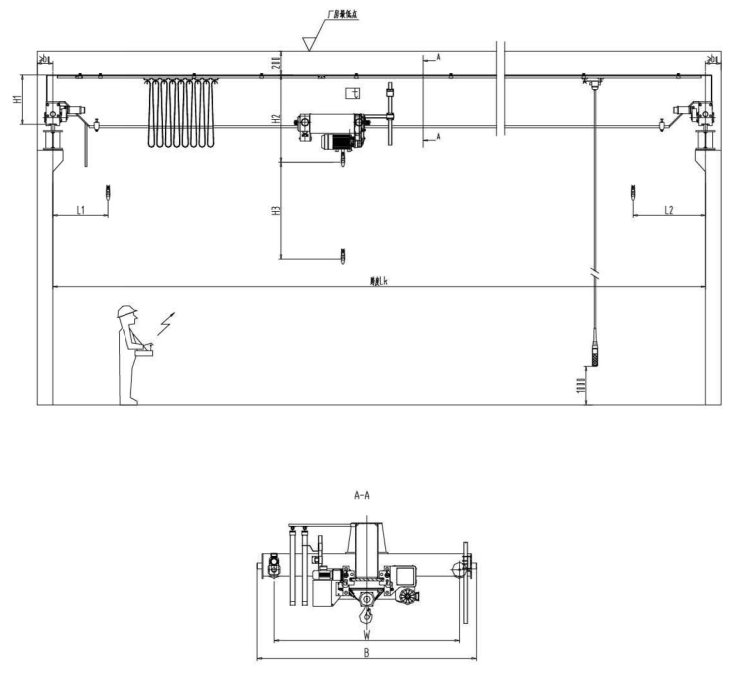

OH Monorail Crane (Overhead Monorail Crane) is a type of material handling equipment used for lifting and transporting heavy loads in a variety of industries such as manufacturing, warehousing, and construction. It consists of a single rail, typically made of steel or aluminum, on which a trolley or carrier is mounted. The trolley or carrier is equipped with a hoist mechanism that can lift, lower, and move the load along the rail.

This type crane is used in conjunction with low clearance electric hoist, rated lifting capacity 3.2t~16t, It is especially suitable for occasions such as material handling and precision assembly of large parts that require precise positioning. The working ambient temperature is -25-45°C.

The main components of an overhead monorail crane

Monorail: A single rail that serves as the path for the trolley or carrier.

Trolley/Carrier: A wheeled device that travels along the monorail, carrying the hoist and the load. It can be manually pushed or powered by electricity.

Hoist: The lifting mechanism attached to the trolley or carrier, used to raise and lower the load. Hoists can be chain, wire rope, or pneumatic types, and are powered by electricity or compressed air.

Lifting attachment: The component that connects the hoist to the load, such as hooks, slings, or grabbers.

Features

◆ Small size, light weight

◆ Smooth operation, low noise

◆ Anti-corrosion, maintenance-free

◆ Fast action, high reliability

◆ Maintenance-free, self-regulating

◆ Dust-proof design, long service life

Specification

| Item | Description |

| Model | SIC |

| Type | Single Girder Overhead Crane |

| Span | 7.5m - 28.5m |

| Lifting Height | 6m - 35m |

| Max. Lifting Load | 20 tons |

| Rated Loading Capacity | 10t |

| Working Grade | M5 |

| Power Source | 380V, 50Hz, 3-phase |

| Application | Metallurgy, power generation, machinery mining, port, petrochemical, and others |

| Certification | ISO, CE, SGS |

| OEM & ODM | Accepted |

CASE

Want to know how this 10-ton CE-certified monorail crane performs in real-world settings? Explore our project case studies to discover how businesses across various industries are using Sinoko lifting solutions to improve efficiency, safety, and productivity.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

This crane is CE certified and built to meet rigorous international standards, including DIN (Germany), FEM (Europe), and ISO specifications—ensuring robustness, safety, and global compliance.

It’s widely used across sectors such as metallurgy, power generation, machinery, mining, ports, petrochemical, and other heavy‑duty industrial fields—thanks to its precision, reliability, and space‑efficient monorail design.

This single‑girder overhead monorail crane delivers rated lifting capacities up to 10 tons, with spans ranging from 7.5 m to 28.5 m and lifting heights between 6 m and 35 m—meeting a broad spectrum of operational needs.

Its lightweight yet high‑rigidity design minimizes structural support needs, effectively saving on workshop construction investment and maximizing available floor space—ideal for facilities seeking economical material handling solutions.

Designed for ambient operating temperatures from −25 °C to 45 °C, this crane incorporates dust‑proof, anti‑corrosion construction that's smooth in motion, low in noise, and requires minimal maintenance—ensuring long service life and reliable performance.

The crane comprises a monorail rail, a trolley or carrier (manually pushed or electric), a hoist (electric-chain, wire rope, or pneumatic), and versatile load attachments such as hooks or slings—delivering a flexible and precise handling solution for heavy loads.