Overview

Warehouse cranes system plays a central role in improving your work efficiency and productivity.

Warehouse cranes type: warehouse overhead crane, warehouse mobile gantry crane, warehouse jib crane, workstation cranes;

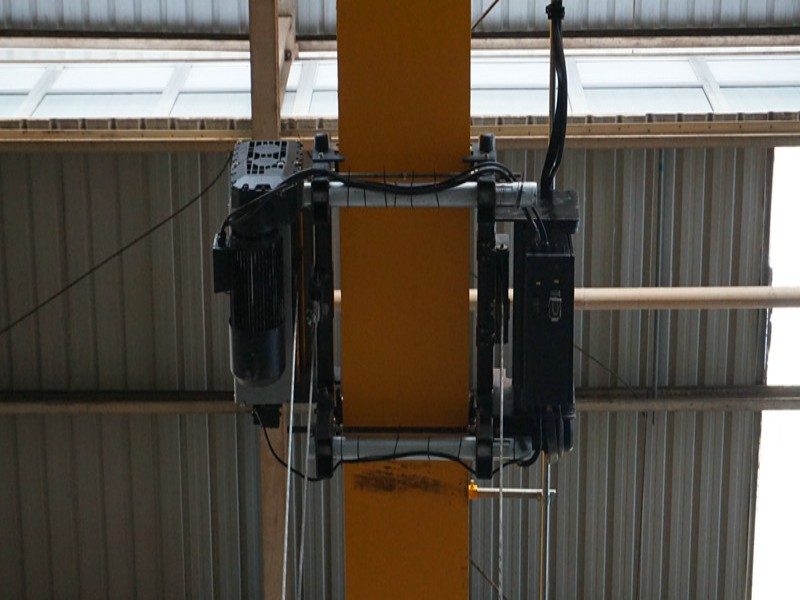

Warehouse overhead crane is installed on the track of the fixed span of the building, consists of bridge frame, cart running mechanism, lifting trolley (with lifting mechanism and trolley traveling mechanism), electrical equipment, etc. There are different types of overhead cranes for you to choose from, including single girder crane, double girder crane, top running crane and underhung crane.

Warehouse mobile gantry crane is manufactured for lifting equipment, loading and unloading of the warehouse, maintaining heavy-duty equipment and transporting materials, applicable for small and medium factory. The best advantage of the crane is Omni-directional movability, fast to assembly, small volume, can be moved to another are only with a minibar.

Warehouse jib cranes is a new generation of light hoisting equipment made for modern production, which is suitable for high-reliability electric chain hoistsSinoko jib cranes are suitable for almost any kind of workstation.

Workstation cranescan be flexible manual, semi-automatic or automatic operation according to the working conditions. Sinokocrane make it free standing crane modular design, the standard profiles are bolted together, easy to installation & transportation.

Features

Compact overall size, Low clearance height, Small wheel load makes warehouse crane can save factory space and investment cost

Advanced technology and excellent professional knowledge makes Sinoko warehouse crane outstanding in the same kinds of hoisting products.

Perfect after-sale service and Rich expertise guidance free you from material handling troubles.

Competitive price and excellent quality makes Sinoko warehouse crane your optimal choice.

There are two distinct control forms supplied for the Warehouse crane , one is ground control with a rope handle, another is the remote control. A customized warehouse crane also would be produced by our company on the basis of clear requirements.

Specification

To buy a warehouse crane perfectly met your workshops requirements, you must have a clear mind in what kinds of specific workshop crane specifications you need for your industry. The main specification of workshop crane is as follows for your reference.

Warehouse overhead crane specification:

| Capacity(t) | Span(m) | Lifting Height(m) | Working Class | Lifting Speed (m/min) | Cross Traveling Speed(m/min) |

1 | 7.5-22.5 | 6/9/12 | FEM2M | 5/0.8 | 2-20(VFD) |

| 2 | 7.5-22.5 | 6/9/12 | FEM2M | 5/0.8 | 2-20(VFD) |

| 3.2 | 7.5-22.5 | 6/9/12 | FEM2M | 5/0.8 | 2-20(VFD) |

| 5 | 7.5-22.5 | 6/9/12 | FEM2M | 5/0.8 | 2-20(VFD) |

| 10 | 7.5-22.5 | 6/9/12 | FEM2M | 5/0.8 | 2-20(VFD) |

| 12.5 | 7.5-22.5 | 6/9/12 | FEM2M | 5/0.8 | 2-20(VFD) |

Warehouse jib crane specification:

| Load capacity | 0.5 to 10 tons |

| Arm Length | 3 m 12 m |

| Rotation angle | 360° |

| Work duty | A3 |

Warehouse mobile gantry cranesspecification:

| Load capacity | 0.25 to 10 tons |

| Span | 2 m 12 m |

| Lifting speed | 2.1 to 11.5 m/min |

| Hoist running speed | 27 to 40 m/min |

| Crane running speed | 42 to 75 m/min |

| Work duty | A4, A5, A6, A7 |

Workstation crane specification:

| Lifting Capacity | 50 kg to 2000 kg |

| Lifting Height | 1 m to 10 m |

| Span | 1 m to 9 m |

| Crane Control Options | Push Button Pendants |

| Hoist Power | electric, manual |

| Hoist Running Power | manual |

Our warehouse cranes are flexible, multifunctional tools designed specifically for a factory environment. Working closely with machine builders, pulp-and-paper experts and engineering companies, we provide you with high-quality cranes and lifting systems built to perform and last.

CASE

Curious how our SEW motor-driven cranes perform in actual projects? Explore real-world case studies to see how Sinoko solutions are applied across various industries.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

This crane delivers reliable performance and smooth operation thanks to its SEW motor technology, high-quality components, and advanced control systems—providing industrial-grade stability and productivity.

With a lifting capacity range of 5 to 100 tons, spans from 10 to 50 meters, lifting heights of 6 to 30 meters, and working duty classes from A3 through A6, this crane offers broad configurability for different workshop environments.

Engineered with multiple safeguards—including stroke, height, overload, emergency limits, as well as protections against phase error, phase loss, overvoltage, and undervoltage—this crane ensures safe, failure-resistant operation.

Featuring a lightweight design and modularized structure, this crane consumes over 30% less energy compared to conventional cranes, significantly reducing operating expenses while meeting energy-saving standards.

Equipped with advanced frequency-conversion control technology for hoisting, the crane enables smooth starts, zero-speed braking, reduced impact during lifting, and precise operational control—refined for modern workshop needs.

Designed for wide industrial compatibility, it operates in ambient temperatures ranging from –20 °C to +45 °C and uses a standard 380 V, 50 Hz, three-phase power supply to accommodate various workshop setups.