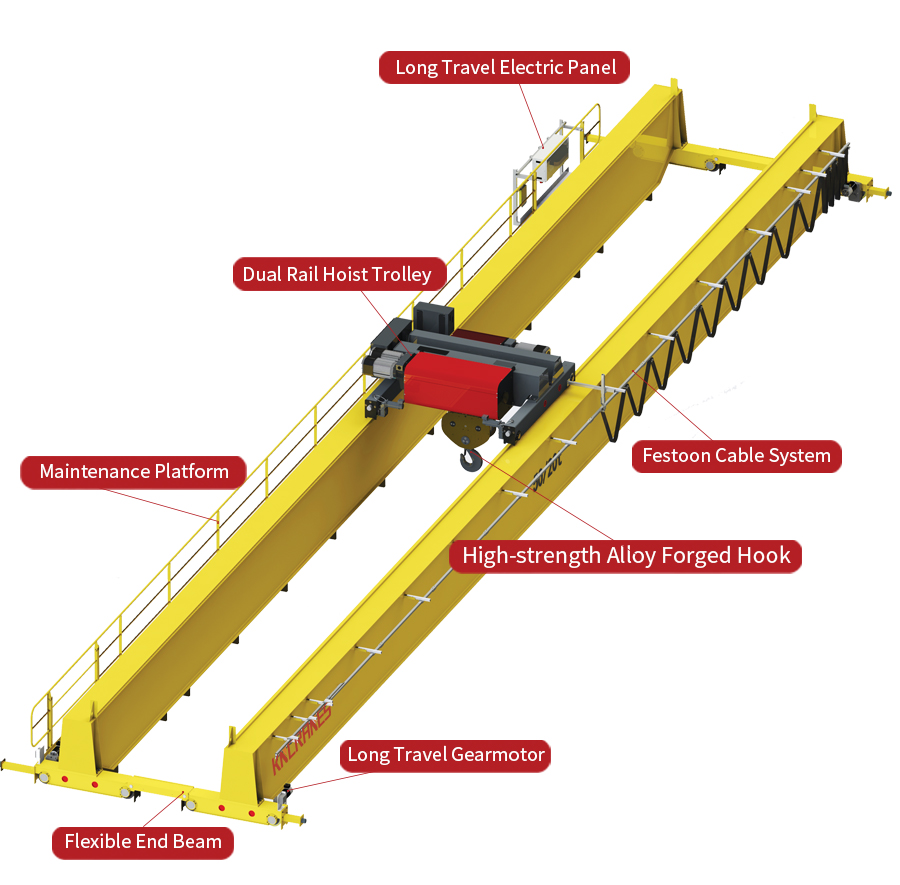

We could produce European Hoist on our own technology. Hoist or Our own brand European hoist are all supplied by us. With the key parts of European Hoist, Stepless speed new electrical overhead traveling crane could run smoothly, durable, variable speed, light weight, smart structure.

Features

Item | Description | Remark |

Crane system | Strong main beams, double end trucks | We have three main girder production lines, use automatic hydraulic pressure of the main girder assembly machine Group, to ensure the main girder of the technical requirements. And we use double-sided automatic submerged arc welding process, to ensure the realization Pre-camber. |

Wheel | Intermedium quenching by top technique machinery | |

Hoist | Work duty: A5 | |

Gear box | The long travelling and trolley are all use three-in-one drive mechanism, variable frequency stepless speed, hardened surface, disc brakes. | |

Buffer | Light weight, cheap, easy maintenance, buffer capacity, in the buffer process can consume 40% of the impact kinetic energy. |

Specification

| Type | New electrical overhead travelling crane |

| Span | up to 35 m |

| Lifting speed | 5/0.38 m/min or customized |

| Traveling speed | 0~40 m/min |

| Cross Speed | 0~100 M/Min (VVVF) |

| Working Class | M3-M6 |

| Specification | CE, ISO |

Our Service

1.Quality Guarantee

For the purpose of “to provide high level cranes for advanced users”, SINOKOCRANES is built on its European crane technology, pursuing reliable and stable quality. The strict, comprehensive quality control system ensure each of our crane products to be safe, functional, elegant and satisfied to our users.

We have professional and rich-experienced inspection and test team. We guarantee that each of our crane has been checked by our quality control engineers.

2. After-Sale Service

We will provide lifelong tracking service for your crane equipment. During crane warranty period, due to our manufacturing result in product quality problems, we will be responsible for repair or replacement parts for free.

We will provide long-term concessional crane spare parts. We have complete sales, after-sale service agent and spare parts inventory, to ensure safe operation of your crane.

After crane successful commissioning, we will be to the buyer’s site not on regular basis, for quality inspection and solve related technical problems on-site.

CASE

Browse our project case studies to discover how Sinoko Crane delivers tailored lifting solutions across diverse industries and working conditions.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

"Stepless speed" refers to the crane’s ability to adjust its traveling and cross‑travel speeds smoothly and continuously via variable frequency drive (VFD), rather than switching between fixed speeds. This allows operators to move precisely and adapt speed to different lifting scenarios, enhancing control and safety.

The crane’s smart structure, lightweight build, and energy‑efficient variable speed controls reduce structural requirements, energy consumption, and maintenance needs. Altogether, these factors help lower overall investment and operating costs while improving ROI.

This crane features strong main girders with automatic hydraulic assembly and submerged‑arc welding, intermediate‑quenched wheels, three‑in‑one drive mechanisms (for long travel and trolley travel) with hardened surfaces and VFD control, plus light‑weight buffers that absorb up to 40% of kinetic energy.

The crane supports spans up to 35 m, lifting speeds of around 5/0.38 m/min (or customizable), traveling speeds from 0 to 40 m/min, and cross‑traveling speeds up to 100 m/min (VVVF). It meets working classes M3–M6 and complies with CE and ISO standards.

Sinoko’s stepless‑speed crane can be equipped with in‑house European‑technology hoists or their own European‑brand hoists. These components deliver smooth, durable, and reliable performance, enhancing the overall quality and longevity of the crane system.

Sinoko provides a comprehensive quality control process, including rigorous inspections by experienced engineers. They also offer lifelong tracking service, free repair or replacement of quality‑related parts during warranty, concessional spare parts, and on‑site technical support after commissioning.