Overview

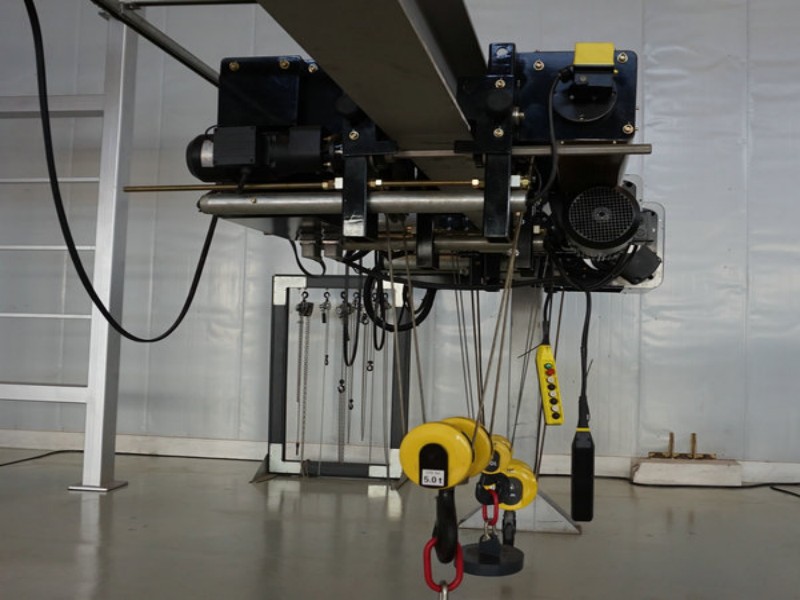

Hoist rope overhead cranes are designed to efficiently handle lifting tasks in industrial environments. Sinokocranes hoist rope overhead cranes are engineered to meet the diverse needs of different industries. Whether it's a basic standard crane or a sophisticated advanced lifting system, Sinokocrane provides solutions that combine reliability, durability, and safety.

Types of Hoist Rope Overhead Cranes

| General CD/MD Electric Hoist Rope Overhead Crane: These cranes feature a CD or MD electric hoist system and are suitable for various lifting applications in industries such as manufacturing, warehouses, and workshops. General CD/MD Electric Hoist Rope Overhead Crane, known for its economical nature, is a cost-effective solution for various industrial lifting needs. Capacity: 0.5~80t Lift Height: 3~35m or customized Span: 3~32m Protection class: IP44/IP54 Working temperature: -20~+40℃ |

| European Standard Hoist Rope Overhead Crane: Compliant with European standards, these cranes offer advanced features and precision, making them ideal for industries with strict lifting requirements such as aerospace, automotive, and heavy machinery. Compared with ordinary cranes, which has light weight about 10%~35%, wheel pressure can be reduced by about 10%~30%, and its height is also reduced a lot. Capacity: 1~80 tons Lift height: Max. 90 m Span: 7.5~40m Work duty: M3~M6 Protection class: IP54/IP55 Working temperature: -20~+60℃ |

Features

(1) Long service life, high safety, never falling off;

(2) Small current, small size, strong output power, high frequency use;

(3) Beautiful appearance of the product, strong anti-corrosion;

(4) The product runs smoothly, heavy objects will not shake;

(5) Reduce factory height, save construction cost, increase effective work area and reduce customer investment;

(6) low noise, energy saving pipe environmental protection, light weight, safe and comfortable handling.

Specification

| Capacity/t | 2 | 3 | 5 | 8 | 10 |

| Span/m | 7.5-28.5 | 7.5-28.5 | 7.5-28.5 | 7.5-28.5 | 7.5-28.5 |

| lifting height/m | 9 | 9 | 9 | 9 | 9 |

| lifting speed m/min | 5/0.83 | 5/0.83 | 5/0.83 | 5/0.83 | 5/0.83 |

| Max.wheel load/kn | 14-28.5 | 18.5-34.4 | 25.2-46 | 43.5-66.5 | 50.5-77.8 |

| crane rail | P18(50*30) | P18/P24 | P24/P38 | P24/P38 | P24/P38 |

| Total power/kw | 2.7/3 | 4.5 | 5.5/5.9/6.2 | 10.6/10.9/12.1 | 10.9/11.2/12.1 |

| Dead weight/t | 1.5-7.6 | 1.6-7.8 | 2-9.4 | 2.6-10.6 | 2.6-11.9 |

| Note: the above data is only partial, can be customized products | |||||

Elevate your lifting operations with Sinokocranes versatile hoist rope overhead cranes. Our comprehensive range of solutions, from general CD/MD electric hoist rope cranes to European standard cranes, ensures there is an ideal option for your specific industrial needs. Contact us today to discuss your requirements and discover how our hoist rope overhead cranes can optimize your lifting processes.

CASE

Want to see how our hoist rope overhead cranes perform in real-world settings? Browse our project case studies to discover how Sinoko cranes are enhancing operations across diverse industries.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

A hoist rope overhead crane is primarily used for lifting heavy loads in industrial environments, where precision and strength are critical. It utilizes a rope mechanism for smooth lifting and lowering, ideal for factories, warehouses, and manufacturing plants.

The hoist rope system uses a strong rope wound around a drum to lift and lower loads. It provides smoother motion and greater control, making it suitable for environments requiring accurate material handling.

Hoist rope cranes offer greater lifting capacity, smoother operation, and reduced wear on the crane’s components compared to traditional lifting systems. This makes them highly durable and reliable for long-term use.

These cranes are commonly used in heavy-duty material handling applications, such as in steel mills, manufacturing plants, construction sites, and automotive factories, where precision and high load capacities are needed.

Yes, hoist rope overhead cranes can be customized in terms of lifting capacity, span, speed, and control systems to meet specific requirements, ensuring optimal performance for your industrial applications.

Routine maintenance includes inspecting the rope, hoist, and other moving parts for wear. Regular lubrication and checking for any signs of wear or tear are essential to ensure the crane operates smoothly and reliably.