Features

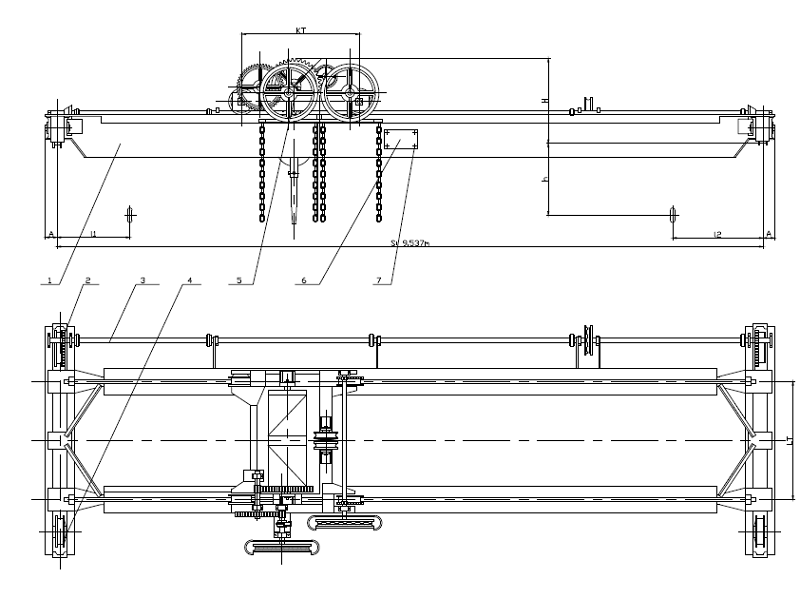

Manual Overhead Crane Main Parts

d. Trolley

All lubricating devices on the manual overhead crane and bearings on the drive shaft need to be filled with lubricating oil (dry oil) once every six months.

During use, the manual overhead crane should be inspected every time to observe whether the machine has abnormal sound and whether the operating performance is sensitive. Check the crane's track every six months without loosening, deformation, etc.

Specification

| Lifting capacity | 1 ton | 2 ton | 3 ton | 5 ton | 10 ton | |

| Lifting height | 3m~10m | |||||

| Working system | A1-A2, Light | |||||

| Travelling speed(m/min) | Trolley | 5.2 | 5.2 | 5.2 | 4.3 | 4.3 |

| Crab | 5.3 | 5.9 | 4.7 | 4.7 | 4.2 | |

CASE

Take a look at more crane project cases to discover how Sinoko equipment is supporting diverse lifting needs across industries. Whether it's overhead cranes, gantry cranes, or customized solutions, our projects show real results in real applications.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

This type of crane is perfect for environments without power—such as older warehouses, light‑duty workshops, or equipment maintenance areas—where reliable, labor‑powered material handling is needed without reliance on motors or electricity.

The crane's movement and lifting are entirely manual, powered by a chain drive. Sinoko's design uses large sprockets to reduce the strain on operators, offering a labor‑saving advantage that makes manual handling smoother and less strenuous.

It comprises four main parts: a main beam, drive and driven wheels, a transmission mechanism, and a trolley. Together, these components ensure accurate beam travel and dependable load control in manual operation.

Careful alignment is critical—rail height deviation should not exceed 1 mm, joint gaps must stay under 2 mm, and track gauge deviation depends on length (6 mm if under 12 m, up to 18 mm if over). Elevation deviation is limited to 1/1000 of the track length, and track deflection should be no more than 3 mm to maintain safe performance.

Lubrication of all moving parts and bearings (especially drive shaft bearings) should be performed every six months with dry oil. Additionally, perform pre-use checks for unusual sounds or performance issues and inspect the track every six months to ensure it remains firm, aligned, and deformation‑free.

The crane offers a lifting height range from 3 m to 10 m. It has a traveling speed around 4.3 m/min for the trolley and approximately 4.7 m/min for the crab, optimized for manual operation in light‑duty settings.