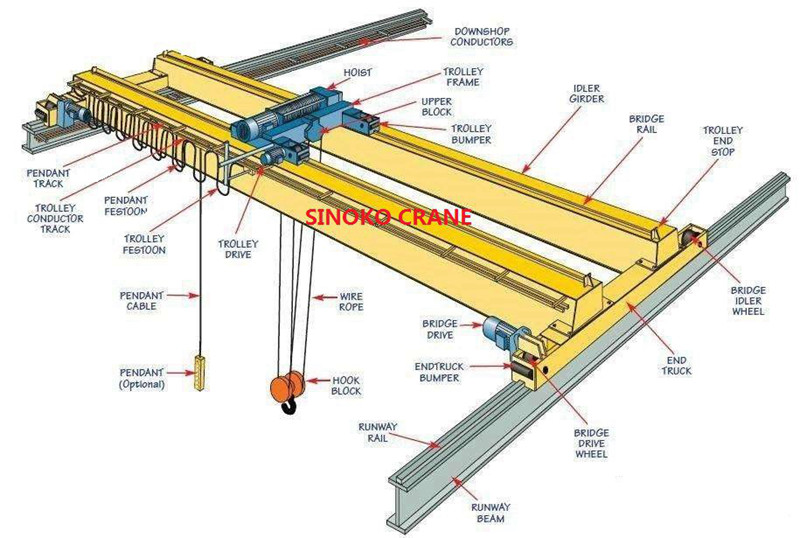

On the beam laid rails for crane crab to transversely move. The beam is weld with the box-shaped end beam. At the middle of the end beam are joints which are fastened with bolts for fragmented transportation of bridges. The platform is used to place trolley traveling mechanism, electric equipments and used for repair.

It has three operation modes: ground handle, wireless remote control and cab. There are two kinds of cab: open cab and closed cab, where there is adjustable seat, insulation mat on the floor, tempered glass for the window, fire proof, cooling fan and auxiliary equipments such as air conditioner, acoustic alarm and interphone which can be furnished according to user demand.

The crane can be furnished with load handling devices such as motor grab, magnet chuck to meet the requirement of hoisting various types of materials.

The crane of a classification group of A3~A7, has a commonly used lifting load of 125t~250t, so that it is suitable to work in factories, warehouse and freight yards where the ambient temperature is -10~40 degree and the relative humidity is not more than 85%. It is prohibited to work in the environment with inflammable, explosive and corrosive gas.

Heavy Duty Double Beam Crane Feature

1.Good reliability, high stability SINOKO bridge crane components of the system are all standard modules, ensure high-efficiency, high-quality function.

2.Favorable performance

3.Smooth starting and stopping

4.Safe and reliable traveling

5.Low noise, commodious cabin and good view

6.Convenient maintenance, excellent exchangeability for parts and components

7.Energy saving,reduce energy consumption

8.Using transducer for travelling or traversing crane to realize step speed or stepless speed change

9. Primer and finishing paint

Heavy Duty Double Beam Crane Specification

| Capacity(t) | 5t--10t | 16t--25t | 32t--50t | 75t--100t | 125t---300t |

| Span(m) | 10.5m---35.5m | ||||

| Lifting height(m) | 6m---30m | ||||

| Control mode | Pendant control, wireless remote control, cabin control | ||||

| Lifting speed(m/min) | 6,7,8,9,10,12 | 1,2.4,3,4,5,6 | |||

| Travelling speed(m/min) | 20,30,45,53,60,75(can add Inverter) | ||||

| Work duty | a) M3: used in places of mild service, such as workshop and warehouse. | ||||

| b) M4: used in places of Medium service such as assembly and depot. | |||||

| c) M5: used in places of medium service, such as machine and assembly shops | |||||

| d) M6: used in places of frequent working such as metallurgy and casting shops | |||||

| Supply power(three phase power) | 380V 50HZ 3Phase (according to user require) | ||||

| Hoist type | Hoist trolley,single or double speed | ||||

| Working ambient temperature | -20℃~ < 55℃ | ||||

| Note | Not suitable for lifting blazing & melting metal or toxicant as well as explosion-proof or insulating working conditions. | ||||

FAQs

Double beam cranes offer higher lifting capacity, better hook height, and increased structural rigidity. For loads like 50 tons, they can distribute forces more effectively across two girders, reducing bending and providing longer life. When span is large or heavy loads are frequent, double beam designs maintain stability and safety better than single girder ones.

These features reduce mechanical shock, minimize wear and tear, and improve safety. Soft start/stop prevents sudden jolts, reducing stress on hoist, girder, trolley, and support structures. Variable speed control (via inverter or transducer) for travelling or traversing allows operators to adjust speed to suit load, environment, or safety concerns—slower in tight or busy areas, faster when moving unloaded or light loads.

The steel structure of our products is generally packaged with plastic film to protect it from rain.

Critical features include limit devices (lift height limit, trolley/eot limit), overload protection, emergency stop functions, hook latch, buffer/rubber bumpers, phase sequence protection, temperature protection on electrical components, laser or other collision warning systems, and having well-certified safety gear. Also check seals, window materials, visibility, structural integrity, electrical grounding, and whether all components meet the duty class you need.

Working class (or duty class) describes how often and heavily the crane will be used. For example: * A3: light or occasional work (warehouses, light assembly) * A5 or A6–A7: more frequent use in industrial or factory conditions (steel plants, foundries, loading yards) If your operations involve continuous heavy loads, frequent lifts, or harsh conditions, you’ll want a higher duty class. Choosing too low can lead to premature wear, higher maintenance, and safety risks.

Ensure the building structure and crane rail supports are capable of sustaining both dead loads (crane self weight) and dynamic loads (moving loads). Measure headroom to ensure crane and hoist/bridge/trolley can operate without obstruction. Plan for approach clearances, cabin clearance, control access, and potential maintenance access. Also check power availability, environmental conditions (temperature/humidity), and whether corrosion or air quality could affect equipment.

Regular inspections of the hoist, trolley, wheels, girders for cracks or deformations. Check electrical systems (insulation, phase sequence, control circuits). Maintain lubrication on bearings, gearboxes, wire ropes. Ensure safety devices (limit switches, buffers, hook latches) are functioning correctly. Monitor noise and vibrations. Replace worn parts proactively, and keep spare parts inventory for critical components.

More Heavy Duty Double Beam Crane Option

Discover more double beam bridge crane models around 50 tons to 500 tons, hoists or magnet/grab attachments, and accessory solutions for different control modes and working conditions to enhance load capacity, safety, and productivity.

Garbage Waste Grab Crane

Sinokocrane is a leading crane manufacturer company in China designed high quality Garbage Waste Grab Cranes for all purpose usage. Quick Click

Learn More Get a QuoteScrap Handling Cranes

Sinokocrane is a leading Crane Manufacturer in China offering wide varieties of Scrap Handling Cranes made up from latest technology. Get free solution.

Learn More Get a QuoteLadle Crane

Sinokocrane manufacture and export quality collection of quality ladle cranes for steel making factories. Our rates are so cost effective. Visit Us today!

Learn More Get a QuoteElectric Open Winch Trolley for Overhead Crane

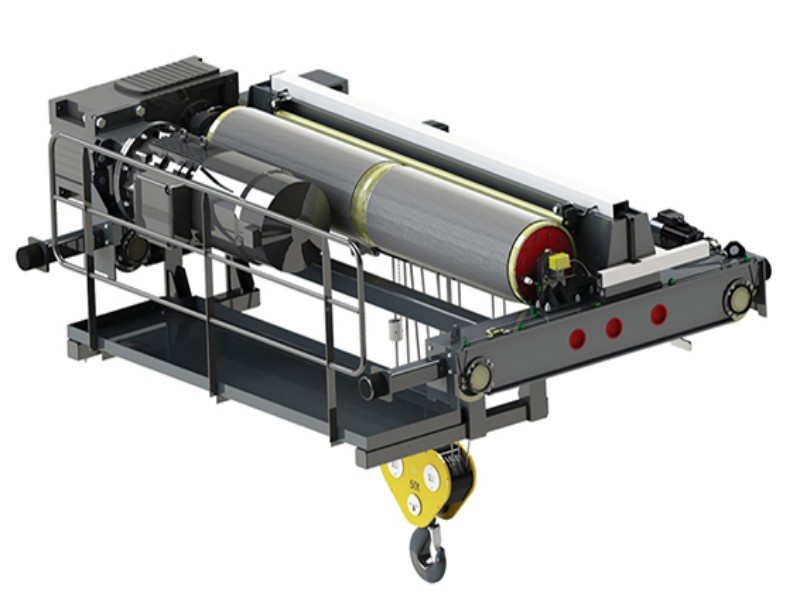

Electric open winch trolley for overhead crane has advantages of high versatility, compact structure, small size, light weight, heavy lifting, and convenient transfer. It is widely used in construction, water conservancy projects, forestry, mines, docks,

Learn More Get a QuoteElectric Hoist For Double Girder Crane

It is a newly developed material handling equipment with advanced design technology according to the FEM standards, European hoist standards, and other regulations. The new serial of European electric hoist is environment-friendly, energy saving and cost.

Learn More Get a QuoteCrane Gearbox

Enhance your crane's hoisting system with our high-quality gearboxes from Siemens, Dongli, and SEW Reducer. Contact us for a quote today!

Learn More Get a Quote