Overview

As a material handling equipment, the 15 ton overhead crane can be used for material lifting and transportation in many different industries. It is the most commonly used type of crane. The crane adopts reliable motors and accessories to ensure high quality and safe work.

Our 15 ton overhead cranes are available in single or double beams depending on the client's work situation, and can be used in lift configurations. All these cranes can be customized according to special requirements.

Overview of Double Beam 15 Ton Overhead Crane

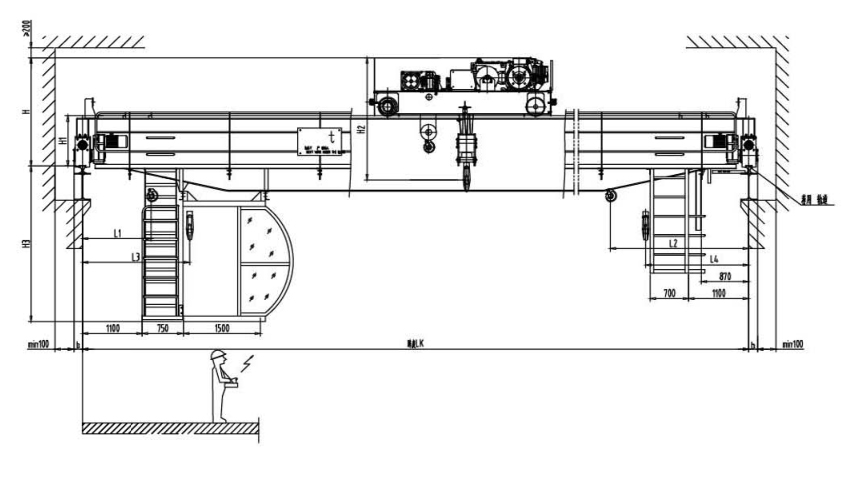

Structure of Double Beam Overhead Crane 15 Ton

•The main girder of bridge crane includes girder box, platform, pantograph and trolley rail.

•The trolley of bridge crane are assembled with motor, reducer, brake, trolley frame, drum, hook, pulley, rain cover and other parts. It includes lifting mechanism and cross traveling mechanism.

The Ground Beam of bridgecranes works as long traveling mechanism, and it combines with beam, Wheel,Motor, Reducer, Brake and Other Parts.

We choose high quality electric parts with rain cover. The power supply mode are cord reel. We could offer the top brand of electricity

Safety system of Double Beam Overhead Crane 15 Ton

• Traveling and lifting limit switch

• Overload protection device

• Voltage lower protection

• Emergency stop function

• Sound and light alarm

• Polyurethane buffer and long service bearing

• Rain cover for hoist, driving and electrical device

Overview of Single Beam 15 Ton Overhead Crane

Compared to double girder cranes, the production cost of single girder cranes is lower than that of double girder cranes because there is less material and shorter manufacturing time for single-girder cranes.

European-style single girder overhead crane has the advantages of small size, light weight, small headroom, and high lifting height.

Lifting capacity: 15 ton

Span length: 6 to 31.5m

Features

• Reasonable structure and favorable performance.

• Smooth starting and stopping.

• Safe and reliable traveling, long life.

• Low noise, commodious cabin with good view.

• High quality automatic welding and NDT inspection.

• Crane drive: IP54, level F insulation.

• Designed according to your reques.

Specification

Specification of Double Beam Overhead Crane 15 Ton

| Capacity | 15 tons |

| Span | up to 35 m |

| Lifting speed | 5/0.38 m/min or customized |

| Traveling speed | 0~40 m/min |

| Cross Speed | 0~100 M/Min (VVVF) |

| Working Class | M3-M6 |

| Specification | CE, ISO |

Specification of Single Beam Overhead Crane 15 Ton

| Capacity | 15 tons |

| Lift height | Max. 90 m |

| Span | 7.5~40m |

| Work duty | M3~M6 |

| Protection class | IP54/IP55 |

| Working temperature | -20~+60℃ |

15 Ton Overhead Crane Price

Customer's Price Concerns:

1. Cost-effectiveness: Customers are interested in finding the best value for their investment.

2. Budget planning: They want to determine if the price fits within their allocated budget.

3. Competitive analysis: Customers compare prices among different suppliers to make an informed decision.

The tonnage, span, lifting height and stroke of the crane are all factors that affect the price. We only know that the tonnage cannot calculate the price. When the tonnage is determined, we need to know the span, lifting height, stroke and other factors.

Why is the price of the overhead crane related to these factors? Because these factors all affect the amount of materials used in the crane, for example, a crane with a span of 20 meters and a lifting capacity of 15 tons is definitely more expensive than a crane with a span of only 10 meters. In addition, cranes with different spans may have different manufacturing process requirements.

| Model | Customization Range | Reference Price |

| Single Girder Overhead Crane | Capacity: 10-32 ton | $ 6500 – 30000 |

| Span: Up to 31.5m (customization) | ||

| Double Girder Overhead Crane | Capacity: 10-100 ton, (Can Up to 500ton) | $ 15000 – 180000 |

| Span: Up to 31.5m (customization) |

Sinoko is a manufacturer specializing in the production of bridge crane and gantry cranes. If you want to know how much a 15 ton overhead crane costs, please contact us. After confirming various parameters, we will provide customers with a detailed quotation.

CASE

At Sinoko Crane, we don’t just build cranes—we deliver complete lifting solutions tailored to each client’s industry and environment. Our project case studies offer insight into how our equipment performs in the field. Explore these real-world examples to discover how our cranes are helping businesses improve efficiency, safety, and reliability worldwide.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

A: Our European‑design model adopts a compact, low‑headroom structure with lightweight components and efficient transmission, enabling higher lifting heights and better space utilization compared to traditional overhead cranes.

A: Absolutely. We customize key parameters including span (up to 35 m), lifting speeds, travel speeds, working class, and control options—whether pendant, wireless remote, or cabin—to match your operational needs.

A: The crane includes comprehensive safety features: travel and lift limit switches, overload protection, low‑voltage protection, emergency stop, sound & light alarms, polyurethane buffers, durable bearings, and rain covers for electrical components.

A: Typical specs include capacity of 15 tons, spans up to approximately 35 m, lifting speed around 5/0.38 m/min, long-travel up to 40 m/min, cross‑travel with VVVF control up to 100 m/min, and working duty class ranging from M3 to M6. The crane meets CE and ISO standards.

A: It serves a wide range of heavy‑duty environments including factories, workshops, warehouses, steel plants, machinery manufacturing, metallurgy, and continuous production lines—ideal for general loading, unloading, and material transportation.

A: The European design’s compact structure, optimized transmission, and modular build reduce self‑weight and headroom requirements while increasing transmission efficiency and reducing maintenance demands—resulting in better energy usage and operational productivity.