Overview

Single girder bridge cranes are widely used in workshops, warehouses and stockyards of machinery manufacturing workshops, metallurgical workshops, petroleum, petrochemical, ports, railways, civil aviation, power stations, paper-making, building materials, and electronics industries. It has the advantages of compact dimensions, low building clearance, light weight, and low wheel pressure.

Features

1. The new European single-girder crane belongs to the ultra-low headroom crane. Its hoisting mechanism adopts low headroom electric hoist, which increases the hook service space to reduce plant height and cost.

2. The product is widely used in the work environment with -25 °C ~ +50 °C, workshop plant clearance is low place. because it has the advantages of stable operation, compact structure, good rigidity, flexible operation, low noise, safety, reliability, modeling, etc.

3. The new European standard electric single girder bridge crane is designed and manufactured according to European FEM standards. It has the advantages of strong rigidity, light weight, and superior structural design.

4. the product is widely used in machinery manufacturing, metallurgy, petroleum, petrochemical, ports, railways, civil aviation, electricity, food, paper, building materials, electronics and other industries. Materials handling occasions such as cargo yards and warehouses. It is especially suitable for materials handling, precise assembly of large components, etc. that require precise positioning.

5. The operation mode is mainly ground handle operation or remote control operation.

6, the series of products are both ordinary and hanging type.

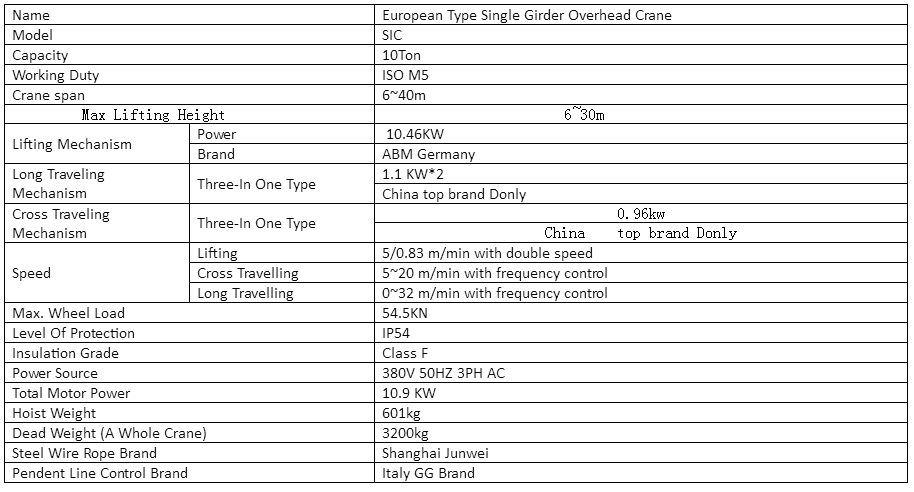

Specification

CASE

Interested in seeing how our 10-ton European standard bridge cranes are applied in real-world industries? Explore our project case studies to see how Sinoko cranes are driving efficiency and safety across various sectors.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

The 10-ton European standard bridge crane with pendant line control is a high-performance lifting solution designed to provide safe, efficient material handling in industrial environments. It offers precise control via pendant lines, making it ideal for a wide range of lifting tasks.

European standard bridge cranes are designed for high reliability, safety, and efficiency. They feature advanced technology, better load handling, and quieter operation compared to traditional cranes, ensuring optimal performance in demanding environments.

Pendant line control allows the operator to control the crane from a distance, providing better visibility and safer operation. It is particularly useful in applications where the operator needs to move along with the crane or work in tight spaces.

This crane is ideal for industries such as manufacturing, automotive production, construction, and material handling, where high lifting capacities and precision control are required for efficient operations.

Yes, the crane can be customized to meet specific operational needs. Options include varying lifting speeds, spans, hoist types, and control systems to suit particular industrial requirements.

Routine maintenance includes checking the pendant control system, inspecting the hoist and lifting components, ensuring proper lubrication, and performing load testing. Regular inspections help maintain safe and smooth crane operation.