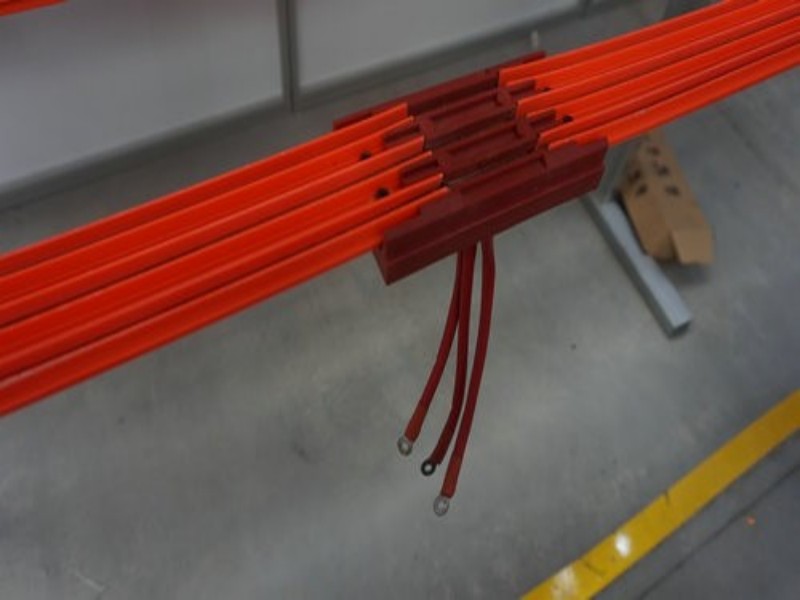

Seamless crane conductor bus bar can be used for electric hoist, electric beam and electric single girder bridge crane; stacker, automatic detection line for electromechanical products, automated production line, mobile power tools and other mobile power receiving equipment, as well as factories, mines, workshops. At present, the H class safety bus bar is generally used, which has great improvement in protection level and insulation, and is safe and reliable.

Features

1. It is easy for installation and daily maintenance with combined design, especially suitable for working at heights.

2. It has long service life and unique conductor jacket design, which greatly extends the service life of the bus bar system.

3. It is safe and reliable, that is, there is no danger of electric shock when using finger contact, and it complies with IP23 standard.

Specification

1. Safety: the bus bar is made of engineering plastic with high insulation performance. The enclosure protection level can be IP13. IP55 is needed to protect against rain, snow, frost and freezing attacks as well as foreign objects. The bus bar is subject to a variety of environmental conditions.

2. Reliability: the bus bar has excellent electrical conductivity, fast heat dissipation, low impedance value and low line loss. The brush is made up of a metal copper or carbon alloy material having high electrical conductivity and high wear resistance. The conductive device has flexible movement and good directional performance, which effectively controls the contact arc and the arc phenomenon.

3. Economy: seamless crane conductor bus bar has simple structure, high allowable current density, low resistivity and low voltage loss, and can save about 10% of electricity. It realizes plastic-made steel to replace copper with plastic.

| NAME | CHARACTERISTICS & APPLICATION |

| Multi-pole seamless bus bar system | 1. Small current pass rate 2. Direct contact with air, not closed, not insulated, not waterproof 3. Price preferential benefit |

| Single-pole slider wire bus bar system | 1. High current pass rate 2. Each pole bus is independent, closed, insulated and waterproof 3. Installation space required is relatively large |

Multi-pole enclosed bus bar system | 1. High current pass rate 2. Four internal contact points 3. Closed, insulated, waterproof 4. Save installation space |

| Copperhead conductor system | 1. Stable operation, large heat dissipation surface 2. Suitable for high temperature, high dust, high corrosive gas environment 3. Withstand strong short-circuit impulse current 4. Copper conductor reduces power loss, 5. Compact structure and easy installation |

| Drum system | 1. Constant force drive. 2. Convenient torque adjustment device. 3. The equipment is steadily retracted and easy to maintain 4. Mainly suitable for large outdoor equipment |

CASE

Curious how our seamless crane conductor bus bar performs in real-world settings? Explore project case studies where Sinoko power supply systems are integrated into cranes and material handling solutions across various industries. Discover how our technology supports safe, efficient, and reliable crane operations worldwide.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

Sinoko’s seamless bus bar is a joint-free conductor rail system—except at the line feed point—that safely and reliably supplies electricity to moving machinery like electric hoists and bridge cranes. Its streamlined design reduces connection points and potential failure spots.

This system offers compact design, easy installation, strong insulation with PVC housing, long service life, and IP13 to IP55 protection levels. It's impact- and UV-resistant, making it ideal for curved rail hoists and low-frequency operation.

Equipped with high allowable current density, low resistivity, and efficient heat dissipation, Sinoko’s seamless bus bar reduces line losses and can save around 10% in electricity usage compared to traditional systems.

Yes—its engineering plastic construction offers excellent insulation, and it complies with IP23 (with some configurations supporting up to IP55), ensuring user safety even if someone touches it mistakenly.

It’s highly versatile—suitable for electric hoists, beams, single‑girder cranes, stackers, production lines, mobile power tools, workshops, factories, and mines. The durable PVC housing also makes it ideal for UV-exposed and impact-prone settings.

While designed for durability, the collector shoes may require periodic replacement due to wear. Additionally, this system is not suitable for explosion‑proof applications or mobile transfer carts and should be inspected regularly to ensure reliability.