Overview:

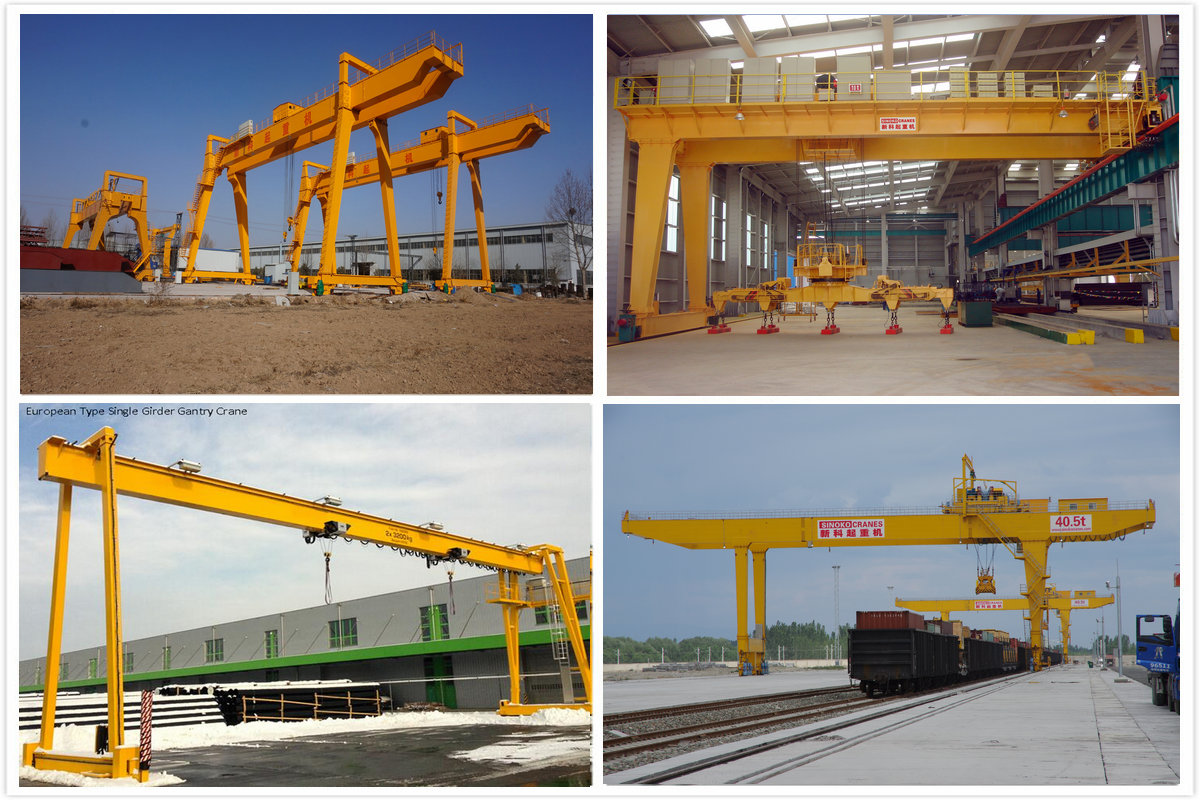

Gantry cranes come in a wide range of designs, including:

1. Adjustable Gantries – used for warehousing applications requiring the movement of materials through aisles, doorways, around obstacles, and over or under obstructions. Welding and fabrication shops can use gantry cranes for lifting parts and equipment into position.

2. Portable Gantries – used for plant maintenance applications requiring replacement and relocation of equipment and machinery. Service truck applications requiring quick knockdown for fast, easy movement to and from a work site.

3. Track-Mounted Gantries – used for applications requiring lifting and moving heavy loads over a fixed route, either manually or motorized.

Features

VVVF Control 15 ton Gantry Crane slowly accelerate from 0 to 20m/min during start-up acceleration with a buffer effect, so the impact force is small. The traditional crane is accelerated from 0 to 20m/min instantly, just as the car does not have a gearbox, the impact force at startup is very large, so it will do some damage to the crane's complete machine.

VVVF Control 15 ton Gantry Crane is relatively stable in operation, which greatly reduces the vibration traction of the steel structure and the factory building. While the traditional cranes fluctuate during the operation, the factory buildings will vibrate at the same time.

Due to the stable operation, VVVF Control 15 ton Gantry Crane basically realizes zero noise during startup and operation. Traditional cranes have loud unusual noise during start-up and operation, especially during start-up. This is caused by instantaneous acceleration and has a greater impact on the structure of the crane.

VVVF Control 15 ton Gantry Crane all use high-tech components and are equipped with frequency converters to provide excellent protection. Therefore, they are not prone to malfunction during the operation. The components and technologies of traditional cranes have been used since the 1970s, and there is no protection for frequency converters, which results in a high failure rate.

Specification

| Mechanism Item | Result | |

| Lifting capacity (ton) | 30 | |

| Lifting height (m) | Main | 10-12 |

| Auxiliary | 10.72-13 | |

| Span (m) | 18-35 | |

| Working environment temperture (℃) | -20~40 | |

| Speed (m/min) | Lifting Speed (Main) | 5.9-9.3 |

| Lifting Speed (AuX) | 8.5-16.7 | |

| Trolley | 34-44.6 | |

| Cab | 34.5-47.1 | |

| Working system | A5 | |

| Power source | 3-Phase A C 50HZ 380V | |

CASE

Discover how the VVVF Control 15-Ton Gantry Crane enhances precision and efficiency in material handling. Featuring Variable Voltage Variable Frequency (VVVF) technology, it offers smooth, controlled movements for safe and reliable operations in diverse industrial settings.

40.5T Rail-Mounted Gantry Crane Installation for Port Logistics Efficiency

The RMG gantry crane designed and manufactured by Sinokocrane has effectively solved the problems for the customers and reduced their operational costs.

Learn More Get a Quote5T Portable Gantry Crane Deployment for Australian Equipment Rental

The portable gantry cranes provided by Sinoko Cranes for the leasing company of Australian customers have significantly increased the number of rentals for the customers and enhanced the revenue of their companies.

Learn More Get a QuoteInstallation of 10T European-Style Gantry Crane for Pakistani Client by Sinoko Cranes

Struggling with slow manual gates? Sinoko's European gantry crane slashed Pakistan customer's downtime by 64%! Transform your access efficiency – contact us!

Learn More Get a QuoteFAQs

The VVVF Control 15-Ton Gantry Crane is designed for precise material handling in industrial settings, including warehouses, factories, and construction sites, with a lifting capacity of up to 15 tons.

VVVF (Variable Voltage Variable Frequency) control allows for smooth and energy-efficient operation, providing precise speed control and reducing wear on components for longer service life and improved safety.

This crane can safely lift loads up to 15 tons, making it ideal for handling medium-weight materials and equipment in various industrial applications.

Yes, the VVVF Control 15-Ton Gantry Crane is highly adaptable and can be customized to suit different operational environments, including indoor and outdoor settings with varying conditions.

The crane offers smoother operations, energy savings, reduced maintenance costs, and precise control over lifting speeds, making it a reliable and cost-effective solution for various lifting tasks.

Routine maintenance includes checking the electrical system, motor, and safety features, as well as ensuring smooth operation of the VVVF control system to keep the crane running efficiently and safely.