Overview:

The main beam of European Standard 10 ton Gantry Crane is a box-type structure, which is optimized by the three-dimensional space of the computer. It is more reasonable and more economical. European Standard 10 ton Gantry Crane is suitable for loading, unloading and transporting along open-air warehouses and along railway lines. Hangers include hooks, grabs, and electromagnetic chucks which can satisfy the using requirements of different occasions. The operating mode can choose the driver's cab operation and remote control operation.

Features

1. Single main beam, welded box shape, degree of crown in accordance with national standards

2. Outriggers with rectangular steel pipe, high strength, small size

3. Steel plate material is Fe37 or Fe52 (similar to domestic steel Q235B or Q345B)

4. The web is cut by 40m CNC to ensure the smooth forming and accuracy of the crown curve

5. Main arc welding with submerged arc welding and nondestructive testing

6. After welding, the entire beam is shot blasted to Sa2.5 level, eliminating welding stress

7. Epoxy zinc-rich paint, two sides and two sides, 140μ thick, long life, beautiful appearance, good gloss

8. The main beam and the end beam are connected by high-strength bolts of grade 10.9 to ensure the structural strength and accuracy of the whole machine

9. Three-in-one vertical drive mechanism for gantry cranes, safer and more space-saving

10. The cart drives IP55, Class F insulation

11. The ground end beam adopts the flat wheel, the cow leg end beam adopts the dual rim wheel and guide wheel

Specification

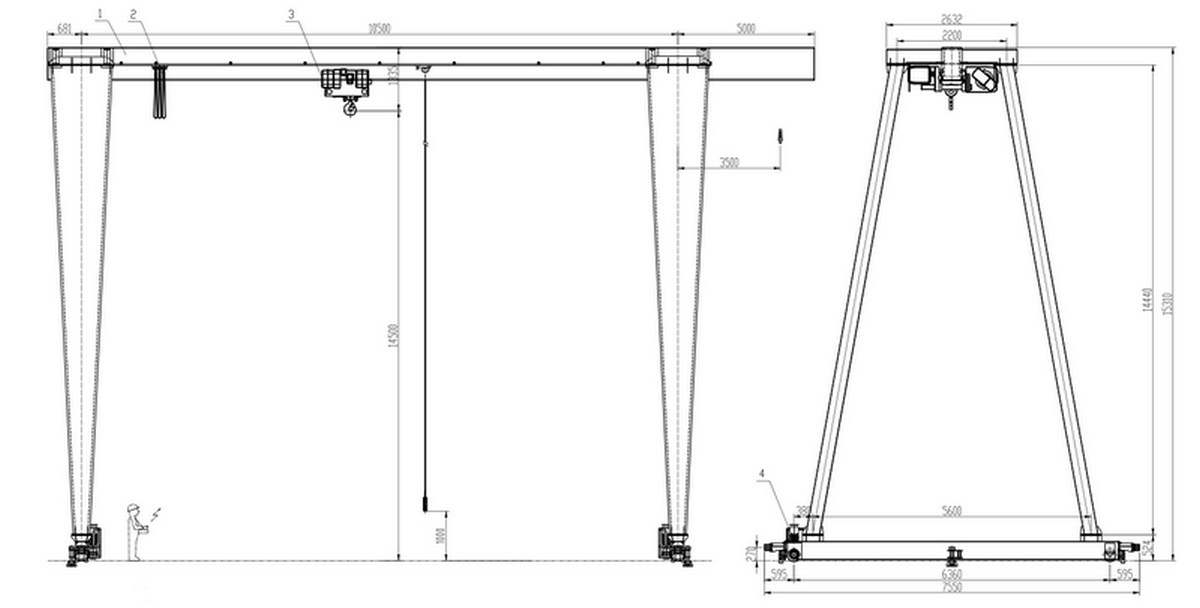

| Capacity | 10000kg |

| Span | 10.5m |

| Lifting Height | 14.5m |

| Lifting Speed | 0-5m/min |

| CT Sped | 2-20m/min |

| LT Speed | 3-30m/min |

| Crane class | A5 |

| Max. wheel load | 69KN |

If you have special requirements on the crane, please contact us and we will give you a customized solution.

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

40.5T Rail-Mounted Gantry Crane Installation for Port Logistics Efficiency

The RMG gantry crane designed and manufactured by Sinokocrane has effectively solved the problems for the customers and reduced their operational costs.

Learn More Get a Quote5T Portable Gantry Crane Deployment for Australian Equipment Rental

The portable gantry cranes provided by Sinoko Cranes for the leasing company of Australian customers have significantly increased the number of rentals for the customers and enhanced the revenue of their companies.

Learn More Get a QuoteInstallation of 10T European-Style Gantry Crane for Pakistani Client by Sinoko Cranes

Struggling with slow manual gates? Sinoko's European gantry crane slashed Pakistan customer's downtime by 64%! Transform your access efficiency – contact us!

Learn More Get a QuoteFAQs

This crane excels in open-air warehouse and railway loading/unloading operations, ensuring efficient material handling in medium-duty industrial environments.

It uses a single welded box‑type main beam, optimized via 3D design, shot‑blasted to Sa2.5, coated with 140μ epoxy zinc‑rich paint, and bolted with Grade 10.9 fasteners for enhanced strength and precision.

It supports a 10,000 kg capacity, a 10.5 m span, and up to 14.5 m lifting height, with lifting speeds up to 5 m/min, cross‑travel speeds of 2–20 m/min, and long‑travel speeds of 3–30 m/min.

Operators can choose between driver’s cab control or remote‑control operation to suit different site setups and safety preferences.

The crane supports various hoisting attachments—including hooks, grabs, and electromagnetic chucks—to meet diverse industrial lifting needs.

Yes. If you require adjustments in capacity, span, height, or other specifications, Sinoko provides tailored solutions to align with your unique operational needs.