Overview

Warehouse Overhead Traveling Crane is a type of crane system used in warehouses for a variety of material-handling duties. These cranes are operated by an operator in a cabin located at one end of the crane system and allow loads to be moved from one part of a warehouse to another. The cranes can be used to transport bulky items, store items in high places, stack and un-stack items, and move items between different departments.

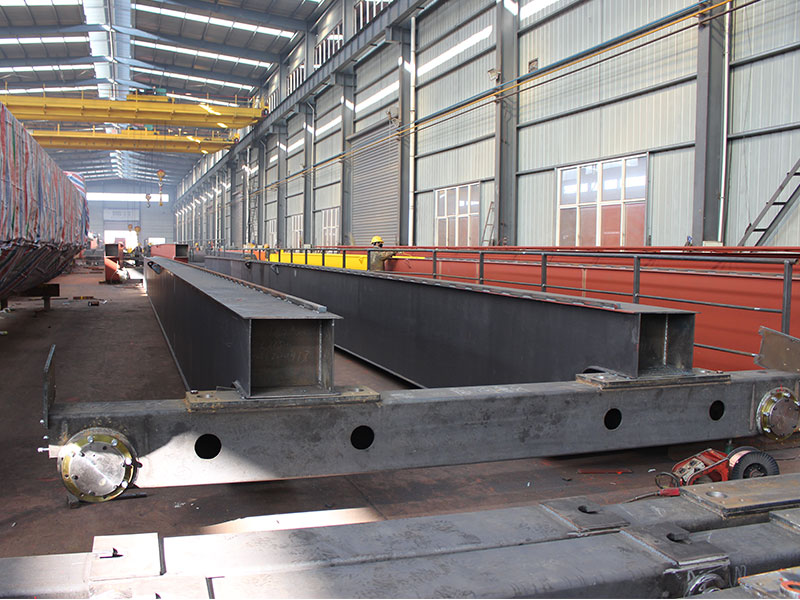

The warehouse overhead traveling crane has two types: single girder and double girder. It consists of a bridge, end girder travelling mechanism, winch trolley/hoist, and electrical appliances.

1. Design: Compact dimensions, low weight, easy to operate and easy to maintain;

2. Motors: Crane uses sturdy cylindrical/ conical rotor pole-changing motors with elegant continuous cast aluminum sections, integrated safety brakes insulation class F, IP54 protection

3. Gear Boxes: Precision flat helical spur gear units in light alloy housings with case-hardened gears, high-grade surface treatment and permanent oil/grease lubrication.

4. Brakes:Single/ Dual-disc electromagnetic DC brakes featuring automatic braking on power failure.

5. Electrical Panel: Modular design, covering a very wide operating range.

6. Painting: Every component & part is thoroughly scrubbed & painted with two coats of primer before assembly & two coats of synthetic enamel after testing.

7. Lifting trolley is very advanced, such as Schneider Electric, ABM / Nord / SEW triple gear motor (triple motor, gearbox, brake), galvanized high-strength steel wire rope, self-adjusting disc brakes, hardened gear reducer, programmable lift limit Bit switches and so on.

Features

1. Safe and reliable: advanced safety technology is adopted to ensure the safety performance of the crane;

2. Compact structure: Adopt compact structure design to reduce the floor area;

3. Simple operation: man-machine interface, simple operation;

4. High efficiency: the use of advanced technology, improve the working efficiency of the crane;

5. Easy maintenance: reliable maintenance technology is adopted to ensure the reliability of the crane.

Specification

Capacity:1ton-200ton

Span:6m-31.5m

a) work duty: FEM2M, M5

b) Protection class: IP55

c) Insulation class: F

d) continuing rate: 60% ( for the high class motor)

e) Cooling rate: 30% than normal crane

f) Over temperature protection: 170℃

CASE

Interested in how this roof-mounted overhead crane is applied in actual warehouse and industrial settings? Explore our project case studies to discover tailored lifting solutions we've delivered across different industries, helping clients improve space utilization, safety, and operational efficiency.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

The design leverages the building’s roof as the runway, eliminating extra beam structures and maximizing plant space—this makes it an economical, space‑saving solution particularly suited to low‑clearance facilities.

This crane is widely used in warehouses, workshops, manufacturing facilities, logistics centers, and other industrial environments that demand reliable lifting and transport while conserving floor space.

As a single‑girder, roof‑mounted system, it uses less steel and material compared to traditional double‑girder cranes—resulting in lower material, installation, and structural load costs, along with reduced energy usage.

The crane integrates essential safety components such as overload protection, limit switches, emergency stop systems, and insulated electrical controls—ensuring safe operations even in demanding warehouse environments.

Sinoko offers flexibility in span, lifting height, and load capacities—allowing adaptations to diverse on‑site conditions. Customers can tailor configurations to optimize the crane for their specific warehouse dimensions and application requirements.

This type of crane saves on construction cost by integrating into existing structures, increases usable headroom for operations underneath, and delivers efficient material flow without requiring new runway installations—delivering high ROI in retrofit or space‑constrained projects.