European type single girder overhead cranes have such design concepts as small dimension, light dead weight. Compared with traditional cranes, the limiting distance is minimum from hook to wall, and headroom is the lowest, which makes cranes work more close to the front, and lifting height more higher that increases effective working space of workplace.

European Type Single Overhead Cranes Features

1.Light Weight Design

e).It uses advanced processing technology and high -quality imported components. Its failure rate has been greatly reduced compared to traditional GB crane, helping customers reduce operating costs.

European Type Single Overhead Cranes Specification

Capacity(kg) | Span(m) | Lifting Height(m) | Lifting speed(m/min) | Max.Wheel Load(KN) | Total Power(KW) | Total Weight(T) |

2000 | 7.5 | 9 | 5/0.83 Double speed | 14 | 2.7 | 1.5 |

10.5 | 15.5 | 1.85 | ||||

13.5 | 16.2 | 2.2 | ||||

16.5 | 18.5 | 3 | ||||

19.5 | 19.9 | 3.5 | ||||

22.5 | 22.5 | 4.8 | ||||

25.5 | 24 | 3 | 5.8 | |||

28.5 | 28.5 | 7.6 | ||||

3200 | 7.5 | 9 | 5/0.83 Double speed | 18.5 | 4.5 | 1.6 |

10.5 | 19.8 | 2 | ||||

13.5 | 20.9 | 2.3 | ||||

16.5 | 23.4 | 3.3 | ||||

19.5 | 24.6 | 3.8 | ||||

22.5 | 28 | 4.8 | 5.2 | |||

25.5 | 29.9 | 6 | ||||

28.5 | 34.4 | 7.8 | ||||

5000 | 7.5 | 9 | 5/0.83 Double speed | 25.2 | 5.5 | 2 |

10.5 | 27.6 | 2.7 | ||||

13.5 | 30.2 | 3.2 | ||||

16.5 | 32.6 | 4 | ||||

19.5 | 35 | 5.9 | 5 | |||

22.5 | 38 | 6 | ||||

25.5 | 42.5 | 7.3 | ||||

28.5 | 46 | 6.2 | 9.4 | |||

8000 | 7.5 | 9 | 5/0.83 Double speed | 43.5 | 10.6 | 2.6 |

10.5 | 45.6 | 3.1 | ||||

13.5 | 48 | 10.9 | 4 | |||

16.5 | 52.7 | 5.1 | ||||

19.5 | 54 | 6.5 | ||||

22.5 | 57.8 | 12.1 | 7.7 | |||

25.5 | 62 | 8.8 | ||||

28.5 | 66.5 | 10.6 | ||||

10000 | 7.5 | 9 | 5/0.83 Double speed | 50.5 | 10.9 | 2.6 |

10.5 | 54.5 | 3.2 | ||||

13.5 | 57 | 4.25 | ||||

16.5 | 60.5 | 5.2 | ||||

19.5 | 63.8 | 11.2 | 6.7 | |||

22.5 | 70 | 8.15 | ||||

25.5 | 73 | 12.1 | 9.25 | |||

28.5 | 77.8 | 11.9 |

FAQs

A single girder European overhead crane is used for lifting and moving loads efficiently within factories, warehouses, and workshops. It features compact design, light weight, and high performance, suitable for modern material handling.

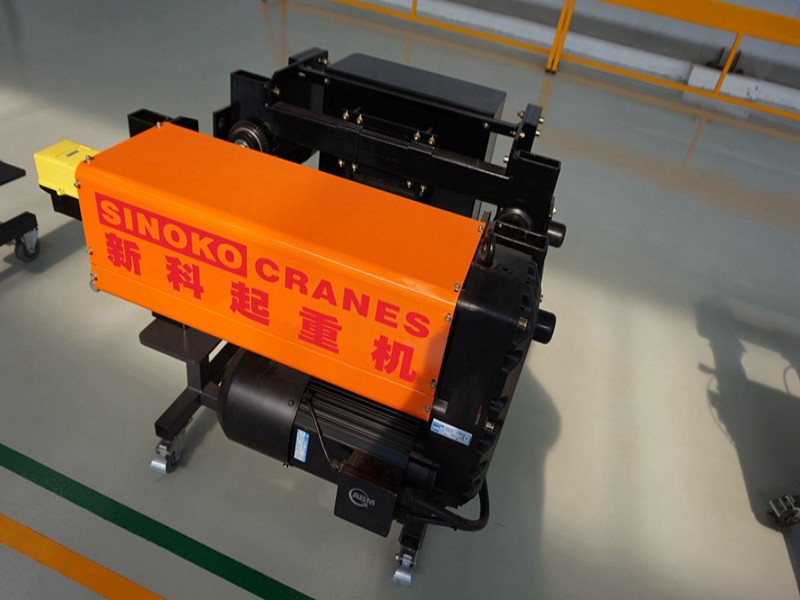

It is equipped with a European type electric wire rope hoist or low headroom hoist for efficient and safe lifting operations.

Yes, we provide complete installation guidance, onsite commissioning, operator training, and after-sales technical support to ensure safe and smooth crane operation.

Related Single Girder European Crane Products

Discover more European cranes and accessories, including double girder overhead cranes, electric hoists, KBK systems, and jib cranes to meet various lifting requirements under different working conditions.

cxtd double girder crane

Maximize efficiency with our European Double Girder Overhead Crane. Perfect for heavy-duty lifting. Contact us for a custom solution today!

Learn More Get a QuoteMonorail Wire Rope Hoist

Looking for a certified monorail wire rope hoist? ISO, CE, SGS approved for safety and reliability. Easy to use. Click to consult and upgrade your lifting!

Learn More Get a QuoteFree Standing Workstation Bridge Crane

Enhance efficiency with a Free Standing Workstation Bridge Crane—an ergonomic, space-saving, and cost-effective solution for workstation material handling. Contact us.

Learn More Get a Quote