Overview

Monorail wire rope hoists are designed to lift and move heavy loads vertically and horizontally. They are versatile and can be used in various applications, such as in warehouses, manufacturing plants, and construction sites. These hoists are often used to transport materials, equipment, and products across different areas within a facility.

Features

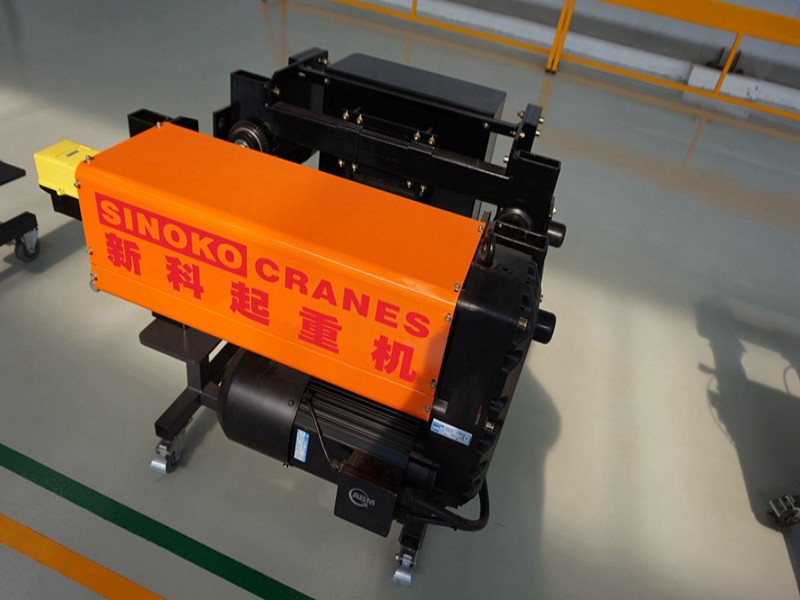

Sinokocrane electric hoist adopts modular design, with high degree of universalization of all parts, high maintenance-free rate, less wearing parts.

Sinokocrane Monorail Wire Rope Hoist Advantages

1. Maximum space using.

2. Precise operation.

3. Low maintenance cost.

4. Less fault downtime.

5. Minimum hook limit space & distance.

6. Top class brand in the world: ABM type motor.

7. SEW 3 in 1 Lifting Mechanism Gear Box.

8. Schneider electric parts.

Specification

| Lifting Capacity | 1~80t |

| Lifting Height | 0~60m |

| Working Class | M3, M6 |

| Ambient Temperature | -20~40℃ |

Contact us now to learn more and take advantage of our exceptional Monorail Wire Rope Hoist. Increase your lifting efficiency and elevate your productivity today!

CASE

Check out more project cases to learn how Sinoko cranes are used across different industries and working environments.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

Using a wireless remote allows operators to stand clear of dangerous loads while maintaining optimal visibility, improving safety and work efficiency—especially in high-risk environments.

The system supports both single girder and double girder setups, as well as top-running and underslung designs, allowing customization to meet specific facility layouts and application needs.

These cranes offer customizable lifting speeds and travel speeds—with the ability to achieve up to 40 m/min traveling and variable cross travel speeds—ensuring smooth and efficient handling.

Built for rigorous use, these cranes meet duty classes from M3 to M6 and conform to CE and ISO standards, making them reliable for demanding industrial operations.

These cranes are ideal for diverse sectors—such as factories, mines, agriculture, construction, docks, and warehouses—offering flexible and safe lifting solutions for installation, cargo handling, and loading activities.

The hoist system comprises a motorized drive, gearing, brakes, drum, rope, load block, and a trolley that travels crosswise along bridge rails—designed for seamless remote control operation.