To satisfy different clients requirement, we take full advantages of combining design by connecting to site condition, specified

fabricate course, possibly make every step easy and customize. In particular, with computer optimization design box beam, low

dead weight effectively reduces the cost in which workshop built with steel structure.

Features

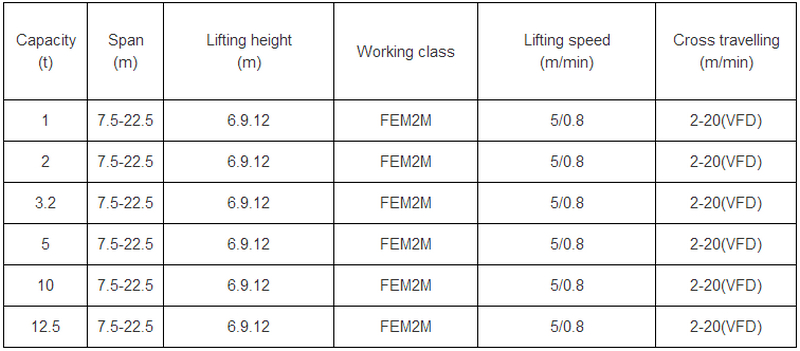

Specification

CASE

Want to see how our single-girder monorail cranes perform in real industrial environments? Browse project case studies showcasing how Sinoko Crane solutions are successfully applied across workshops, warehouses, and production lines. Discover how our cranes deliver reliable lifting performance in action.

3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

Sinoko’s design emphasizes modular construction, precise frequency‑inverter control for smooth motion, integrated safety features like overload limiters and emergency stops, and high‑durability components—delivering consistent performance in demanding operations.

Single‑girder monorail cranes commonly handle loads between about 0.5 t and 20 t, with frequency‑controlled lifting speeds from ~1 to 5 m/min and travel speeds around 5–20 m/min. They support indoor use within standard ambient temperatures and duty classes such as ISO M5 or FEM 2m.

This design requires only one beam—resulting in lower material costs, lighter deadweight, easier installation, and less structural load. It also enables better hook approach and is ideal where headroom is limited.

The crane supports advanced options such as pendant pendants, wireless remote, overheat protection, limit switches for travel and lifting, electromagnetic braking, overload protection, and safety latches—all configurable to meet user safety and operational preferences.

These cranes shine in workshops, assembly lines, warehouses, and production facilities—especially where space is tight, accuracy is critical, and moderate capacity is sufficient. Their compact size and coating options also make them suitable for clean and high‑Use environments.

Single‑girder systems are less suited for heavy‑duty—i.e., capacities beyond ~15 t—or long‑span operations. Additionally, under‑running trolleys may cause beam wear, and specialized features like operator cabins or extensive walkways can be more challenging to adapt.