Top Running Bridge Cranes are lifting devices that are used to lift materials over the workshops, warehouses and stockyards. Because its two ends are located on tall concrete pillars or metal brackets, it looks like a bridge. The bridge crane's bridge runs longitudinally along the rails laid on both sides of the elevated bridge, which can make full use of the space under the bridge to lift materials and is not obstructed by the ground equipment. It is the most widely used and the largest number of lifting appliances.

Features

Single Girder Top Running Bridge Cranes

As its name, the single girder top running Bridge crane made up of just one bridge girder. On the other side has two end carriage and there is also a trolley hoist that travels between the 2 end carriages.

Single girder top running bridge crane is a cost effective choice. The working class can be reach to A5 (M5, 2m). It can be used in Cement Factory, Assembly Warehouse. In addition, Top running Bridge crane can reduces the load on the wheels so this crane helps you save on new support structures.

Top Running Bridge Cranes Structure Advantages

The main steel structures (main beam, end beam) are all made of Q235-B. The manufacture, welding and inspection of steel structures are carried out according to national standards. All the plates are all automatically fed by a CNC cutting machine and the degree of crown of the main beam is preset so as to avoid the problem of lowering the crown of a conventional fire-dried main beam. The steel surface is shot blasted with a surface roughness of Sa2.5 grade in GB8923 Registration of steel surface treatment prior to painting and derusting grade" to improve the paint adhesion, not stripping paint, and guarantee the long-term single-girder crane machine Beautiful

Top Running Bridge Cranes Mechanism Advantages

Single-girder crane lifting mechanism consists of Sino-foreign joint venture brand double-speed electric hoist. The product has the advantages of compact structure, light weight, small size and easy operation.

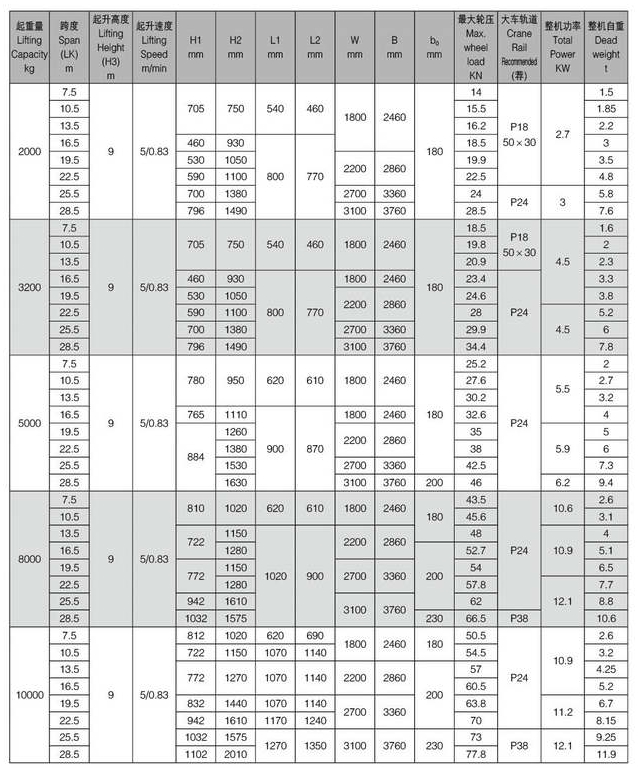

Specification

Welcome to send inquiry to us of top running Bridge crane!

CASE

Curious how our single girder cranes perform in real-world applications? Check out our project case studies to see how Sinoko cranes are enhancing efficiency across industries.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

A single girder top running overhead crane consists of one main bridge girder with the hoist running along the top. It’s ideal for moderate lifting capacities, commonly used in warehouses, workshops, and manufacturing facilities.

Single girder cranes are generally more cost‑effective and lightweight, offering reliable performance for lighter loads (up to 20 tons). Double girder cranes are better suited for heavier loads and longer spans but come at a higher cost.

Top running designs provide greater hook height, longer spans, and less wear on the crane’s components due to reduced friction. This results in increased durability and improved performance.

The typical lifting capacity ranges from 1 ton to 20 tons, making it suitable for lighter to moderate industrial lifting tasks. It can also be customized based on specific requirements.

These cranes are ideal for use in industries like manufacturing, material handling, automotive production, and assembly lines where moderate lifting capacity is needed with efficient space utilization.

Custom options include variable lifting speeds, specialized hoisting equipment, tailored spans, and specific control systems, as well as advanced safety features for added performance and reliability.