Features

1). First class quality with competitive price

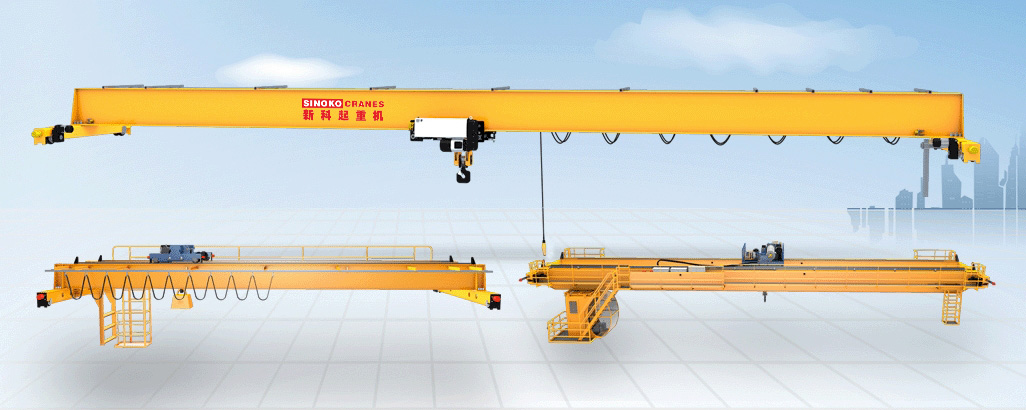

2). Compact design, optimal use of the size of work areas

3). Reasonable structure, favorable performance

4). Control the load easily and position the load exactly

5). Smooth starting and stopping

6). Superiorsafety and reliability

7). Low noise, commodious cabin and good view

8). Minimum Easy maintenance, excellent exchangeability for parts and components

9). Saves electricity specifications

10).One-Stop Shop for your crane and hoist needs

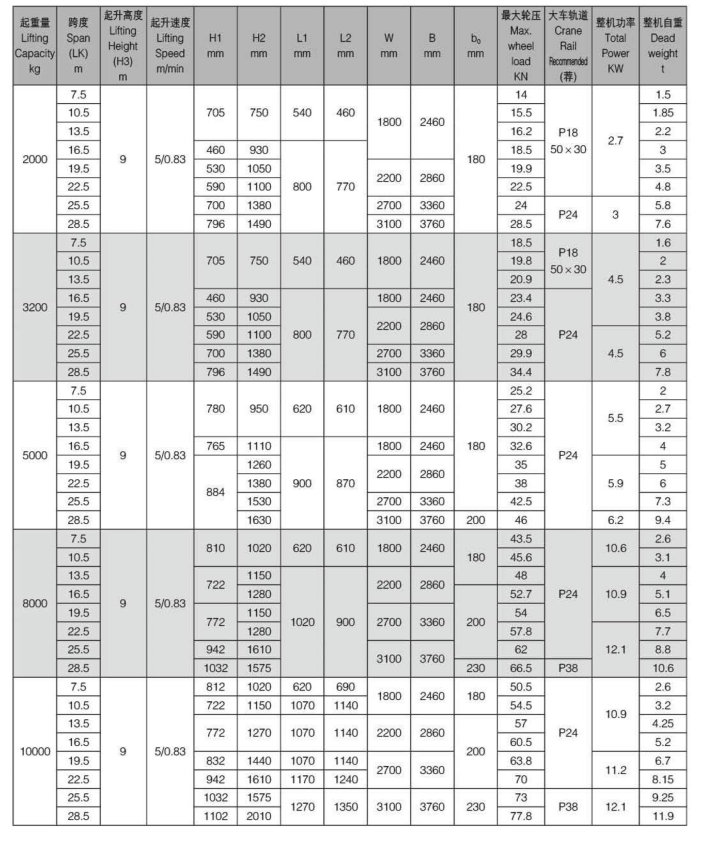

Specification

CASE

Want to see how this crane performs in real-world settings? Browse our project case studies to explore how Sinoko cranes support lifting solutions across industries.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

The wireless remote control enables operators to stay clear of moving loads, offering excellent visibility of both the workspace and the load for safer, more efficient operation.

Its single‑beam configuration reduces overall weight and wheel pressure. The compact structure lowers the building’s headroom requirements and allows mounting on existing roof support systems—saving both materials and installation costs.

Safety features include overload protection, emergency braking, thermal and current protections for the lift motor, safety‑latch hooks, rubber buffers, ground protection, and precise limit switches to help prevent overtravel or accidental overload.

This crane is widely applied in metallurgy, machinery manufacturing, warehouses, ports, railways, mining, construction sites, steel plants, and freight yards—thanks to its adaptability and efficient space utilization.

Common configurations include spans of 7.5 m to 28.5 m, lifting heights between 6 m and 35 m, rated loads up to 20 t (with typical capacity options from 1 t to 20 t), a working grade of M5, and a standard 380 V/50 Hz three‑phase power supply.

Because it's designed to be mounted directly on existing roof structures, this crane eliminates the need for additional runway installations—making it ideal for retrofitting older facilities or optimizing compact spaces.