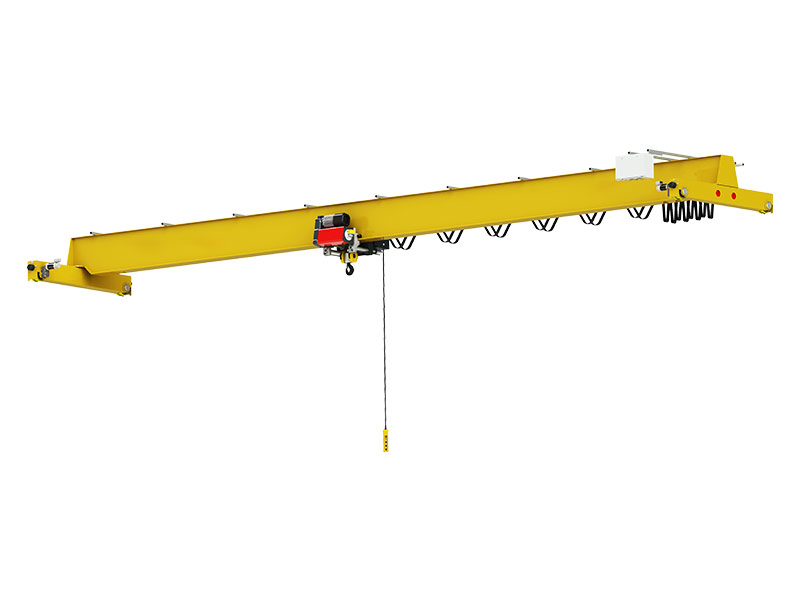

With the continuous decrease in the price of inverters, frequency control will become A superior speed control scheme for lifting machinery, VVVF control material handling 3 ton single girder bridge crane produced by SINOKO Crane, have been applied to various industries, and its excellent performance has been praised and recognized by many customers.

Features

• Smooth acceleration and deceleration - The VVVF control system provides soft start and stop functions, allowing the crane to accelerate and decelerate gradually. This reduces impact on the crane structure and load, minimizing wear and tear.

• Improved efficiency - The VVVF control allows the crane to operate at its optimal speed, maximizing efficiency. It can adjust speed based on the load to optimize performance.

• Energy savings - Since the crane operates at the required speed, not excessively fast, the VVVF control system can reduce energy consumption by up to 30%.

•Increased precision- The ability to finely control speed and acceleration provides more precise control of the crane's movements and positioning of loads. This improves handling accuracy.

• Reduced noise - The smooth and gradual acceleration of the VVVF control system produces less mechanical and electrical noise compared to traditional controllers.

• Improved reliability - The use of modern power electronics and control technology in a VVVF systemmakes it more robust andfault tolerant, leading to higher reliability.

• Advanced protection - A VVVF control system offers integrated protection features overload detectionovervoltage detection, and ground fault detection to safeguard the crane and load.

Specification

| Span | m | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 |

| Crane Weight | t | 1.36 | 1.7 | 2.15 | 3.07 | 3.63 | 5.09 | 5.74 | 7.63 |

| Trolley Weight | t | 0.23 | 0.23 | 0.23 | 0.23 | 0.23 | 0.23 | 0.23 | 0.23 |

| Max. Wheel Load | KN | 19 | 20.6 | 22.1 | 24.4 | 25.9 | 29.5 | 31.2 | 35.9 |

| Min. Wheel Load | KN | 3.8 | 4.1 | 4.9 | 7.1 | 8.3 | 11.8 | 13.3 | 17.8 |

| Crane Wheel Q'ty | PCS | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Crane Rail | P22 | P22 | P22 | P22 | P22 | P22 | P22 | P22 |

Contact Sinoko today to discuss your lifting and material handling needs. Our experts can recommend the ideal crane solution based on your requirements and budget.

CASE

Explore our crane project case studies to learn how Sinoko Crane delivers customized lifting solutions across a wide range of industries. From precision assembly lines to heavy-duty manufacturing, our global installations highlight the advanced performance, safety, and reliability of our material handling systems. Get inspired by real applications for your next project.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

VVVF control ensures smooth, stepless speed regulation for lifting, trolley, and bridge motions, improving positioning precision, reducing mechanical stress, and enhancing operational safety and efficiency.

This crane offers advanced smart functions such as micro‑speed control for fine positioning, load floating to reduce start‑stop shock, sway control to minimize load swing, inching for precise short moves, extended speed range for light loads, and restricted load zones for safety.

Designed following FEM and CMAA70 standards, the crane features an optimized low‑headroom, lightweight European-style structure—perfect for workshops needing efficient overhead lifting without sacrificing ceiling clearance or structural integrity.

The crane is equipped with a comprehensive set of safety measures, including overload limiters, height and stroke limiters, photoelectric sensors, and optional crane “black box” data recording. Other protections like anti‑collision, emergency stops, and phase‑fault safeguards ensure reliable operation.

This model supports custom lifting capacities from 1 to 20 tonnes, with customized crane sizing for span and lifting height. Its design minimizes dead weight and wheel pressure, enhancing efficiency and reducing building load requirements.

Variable speed control, including micro‑speed and stepless adjustment, allows operators to handle delicate, precise lifting tasks with greater control and safety—ideal for assembly lines, machinery handling, or environments requiring meticulous load placement.