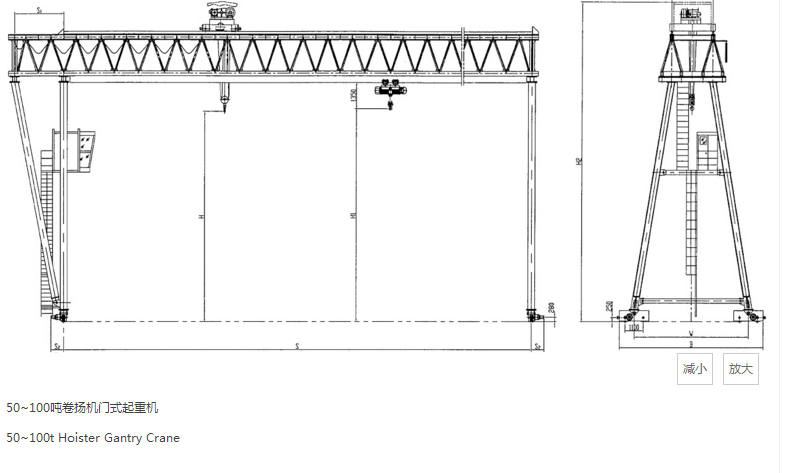

Overview:

100 ton gantry crane is 100(50+50) tons of load, 30m span, 10m HOL; European design, top configuration, such as, Schneider Electric/Siemens main electrical components, Schneider inverter, German brand geared motor, SEW/Siemens, Abm, Fran Germany, etc.;

This product is widely used in the construction of prefabricated beam yards, stone production plants, subway construction shafts, tunnels, and shafts. Used for the installation of related equipment, prefabricated hoisting steel beams, subway slag and other wastes. Under normal circumstances, the lifting height is large and the movement is smooth.

Engineering gantry cranes are suitable for lifting and handling of general loaders in construction workshops such as highways and bridges. Triangular truss is mostly used in the design of the main girder. The leg is made of steel leg structure, and the steel tube is connected with a stabilizer bar into a triangular stable structure. The crane is composed of a bridge frame, a cart operating mechanism, a trolley, and electrical equipment. The entire mechanism is manipulated in the control room. The power supply of crane is divided into two types: cable and sliding contact line.

The gantry cranes technology requirements are as follows:

(1) The main steel structure of the lifting beam door machine must consider the factors of the convenience of disassembly and transportation under the premise of satisfying the strength, rigidity and stability.

(2) The interior of the fuselage should have enough space to meet the assembly of prefabricated beams and bridge erection machines.

(3) When two prefabricated beams are used for lifting, the two machines must be operated synchronously.

(4) The lifting mechanism and running mechanism have a low running speed to improve the accuracy of precast beam alignment and reduce the impact on the structure of the beam elevator.

(5)Lifting beam door machine can also be used alone, or it can be used in conjunction with two heavy objects such as lifting prefabricated beam. If two units are used together, the weight can reach 900 tons. It is an important heavy lifting equipment with high safety performance. Easy to disassemble, install and transport.

Specification

| Mechanism Item | Result | |

| Lifting capacity (ton) | 30 | |

| Lifting height (m) | Main | 10-12 |

| Auxiliary | 10.72-13 | |

| Span (m) | 18-35 | |

| Working environment temperture (℃) | -20~40 | |

| Speed (m/min) | Lifting Speed (Main) | 5.9-9.3 |

| Lifting Speed (AuX) | 8.5-16.7 | |

| Trolley | 34-44.6 | |

| Cab | 34.5-47.1 | |

| Working system | A5 | |

| Power source | 3-Phase A C 50HZ 380V | |

CASE

Discover how the 100T Engineering Gantry Crane can transform your heavy-lifting operations. With a 100-ton capacity, this crane is built for large-scale construction, shipbuilding, and industrial projects. Learn how it improves safety and productivity in demanding environments.

40.5T Rail-Mounted Gantry Crane Installation for Port Logistics Efficiency

The RMG gantry crane designed and manufactured by Sinokocrane has effectively solved the problems for the customers and reduced their operational costs.

Learn More Get a Quote5T Portable Gantry Crane Deployment for Australian Equipment Rental

The portable gantry cranes provided by Sinoko Cranes for the leasing company of Australian customers have significantly increased the number of rentals for the customers and enhanced the revenue of their companies.

Learn More Get a QuoteInstallation of 10T European-Style Gantry Crane for Pakistani Client by Sinoko Cranes

Struggling with slow manual gates? Sinoko's European gantry crane slashed Pakistan customer's downtime by 64%! Transform your access efficiency – contact us!

Learn More Get a QuoteFAQs

The 100T Engineering Gantry Crane is a heavy-duty crane designed to lift and transport large and heavy materials. With a 100-ton lifting capacity, it’s perfect for construction, shipbuilding, and heavy engineering projects.

This crane is commonly used in industries such as construction, shipbuilding, steel mills, and heavy manufacturing. It is ideal for moving oversized materials, large equipment, and structural components in industrial environments.

Features include a high lifting capacity of 100 tons, durable construction, precise control systems, and the ability to handle large and heavy loads. It’s designed for reliable performance even in the toughest industrial settings.

The crane’s powerful lifting capacity and advanced control systems reduce the time and labor required to move heavy materials. Its precision and reliability help improve overall productivity and safety on large-scale engineering projects.

As the name suggests, the crane can lift up to 100 tons, making it suitable for the most demanding tasks. It is perfect for handling large and heavy loads, such as steel beams, machinery, and other industrial equipment.

Routine maintenance includes inspecting the lifting system, checking the structural integrity of the crane, lubricating moving parts, and testing the electrical components. Regular inspections ensure the crane’s long-term reliability and safe operation.