Description of Sinokocranes Wireless Control 45 ton Gantry Crane

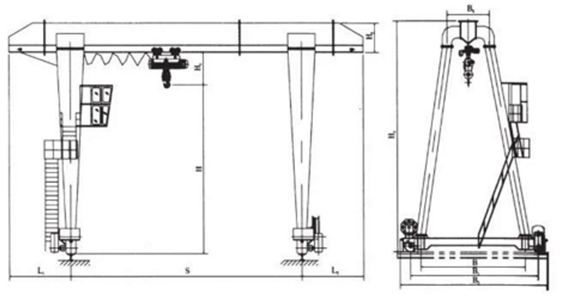

The metal structure of the utility model is like a portal frame, and two support feet are installed under the main

beam, and the utility model can be directly carried on the track of the ground, and both ends of the main beam

can be provided with overhanging cantilever beams.

Due to easily manipulate, a remote control gantry crane is widely used in many working environment, such as

the warehouse, harbor, shipyard, hydro power station and some construct sites.

There are mainly two manipulation methods to choose for customers about a gantry crane. These are the ground

control and cabin control.And also can be divided into two different ways, one is the Panel Push Button Type,

and another is Sway Control with rockers.

As a gantry crane manufacturer, we have quite rich experience in the production and design of cranes. Apart from

the 45 ton gantry crane, we provide cranes with various lifting capacities, such as 15 ton, 20 ton, 30 ton, 80 ton and

so on. also provide semi gantry crane,rubber tired gantry crane and rail mounted gantry crane etc.Using the international standards, 45 ton gantry crane in Sinokocranes is of elegant appearance, flexible operation, safe and reliable performance.

Features & Advantages of Sinokocranes Wireless Control 45 ton Gantry Crane

1. Overload protection device

2. Top quality long time bearing polyurethane materials buffer

3. Crane traveling limit switch

4. Voltage lower protection function

5. Emergency stop system

6. Lifting height limit device

Technical Parameter of Sinokocranes Wireless Control 45 ton Gantry Crane

| Mechanism | Item | Unit | Result | |

| Item | _ | |||

| Linfting capacity | ton | 5-100 | ||

| Lifting height | main | m | 10-12 | |

| auxiliary | m | 10.72-13 | ||

| span | m | 18-35 | ||

| working environment temperture | ℃ | -20~40 | ||

| speed | lifting speed | Main | m/min | 5.9-9.3 |

| Aux | 8.5-16.7 | |||

| Trolley | 35-44.6 | |||

| Cab | 34.5-47.1 | |||

| Working system | _ | A5 | ||

| power source | _ | three-Phase A C 50HZ 380V | ||

We believe that high-classwireless Control 45 ton Gantry Crane with reasonable price would definitely become your superior alternative.Contact us for a quote.

CASE

See how the Wireless Control 45-Ton Gantry Crane enhances safety and efficiency in heavy lifting. With its advanced wireless technology, operators can manage loads up to 45 tons remotely, improving precision and reducing risk in industrial environments.

40.5T Rail-Mounted Gantry Crane Installation for Port Logistics Efficiency

The RMG gantry crane designed and manufactured by Sinokocrane has effectively solved the problems for the customers and reduced their operational costs.

Learn More Get a Quote5T Portable Gantry Crane Deployment for Australian Equipment Rental

The portable gantry cranes provided by Sinoko Cranes for the leasing company of Australian customers have significantly increased the number of rentals for the customers and enhanced the revenue of their companies.

Learn More Get a QuoteInstallation of 10T European-Style Gantry Crane for Pakistani Client by Sinoko Cranes

Struggling with slow manual gates? Sinoko's European gantry crane slashed Pakistan customer's downtime by 64%! Transform your access efficiency – contact us!

Learn More Get a QuoteFAQs

The Wireless Control 45-Ton Gantry Crane is ideal for lifting and transporting heavy materials in industries such as construction, manufacturing, and logistics, with a maximum lifting capacity of 45 tons.

Wireless control provides greater flexibility and safety by allowing operators to control the crane from a distance, reducing the risk of accidents and improving operational efficiency in tight spaces.

This gantry crane can handle loads up to 45 tons, making it suitable for lifting large, heavy materials with ease and precision in various industrial applications.

Yes, the crane can be customized to meet different operational requirements, including adjustments to span, lifting height, and motor power, ensuring optimal performance in diverse environments.

The wireless control system allows operators to stay at a safe distance from the load and crane, reducing exposure to potential hazards, while providing real-time monitoring for better decision-making.

Routine maintenance includes inspecting the wireless control system, electrical components, and mechanical parts. Regular checks help ensure smooth and safe operation of the crane over time.