The 40-ton bridge crane belongs to the category of overhead cranes, specifically designed to span the width of the working area using a bridge structure. It operates on an elevated track, allowing the crane to move horizontally along the length of the area, while the lifting mechanism moves vertically to lift and transport heavy loads.

Features

Impressive Load Capacity: With a weight-bearing capacity of 40 tons, this bridge crane is built to tackle heavy-duty lifting tasks, making it ideal for industries that require handling large and cumbersome objects.

Smooth and Precise Movements: Equipped with advanced controls and precision engineering, the 40-ton bridge crane ensures smooth and accurate movements, enabling operators to maneuver heavy loads with ease and safety.

Flexible Span: This crane offers a versatile span range, allowing it to cover a significant area within your facility. It can be customized to suit your specific requirements, ensuring optimal coverage for your lifting operations.

Durable Construction: Constructed with high-quality materials and components, this bridge crane is built to withstand heavy usage and harsh industrial environments. Its robust design ensures long-lasting performance and minimal maintenance requirements.

Safety Device of 40 ton Bridge Crane

♦ Lifting and travelling limit switches

♦ Emergency Stop

♦ Loss voltage protection

♦ Grounded protection

♦ Overload protection

♦ Short circuit protection

♦ Overheating protection

♦ Overspeed protection

♦ Overcurrent protection

♦ Faulted phase protection

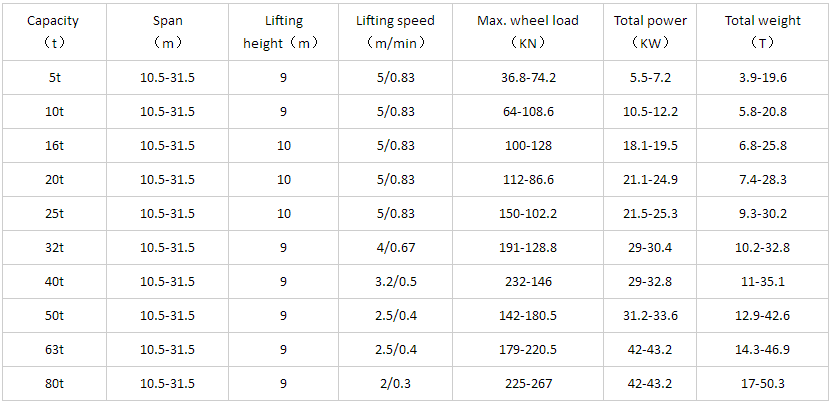

Specification

CASE

Discover our crane project case studies to explore how Sinoko Crane delivers tailored, high-performance lifting solutions across various industries. From large-scale manufacturing plants to logistics hubs, our real-world applications demonstrate the reliability, safety, and efficiency of our overhead crane systems. Get inspired for your next lifting project.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

This heavy-duty crane is ideal for demanding settings like factories, warehouses, and construction zones where precision and large-load handling are critical.

Users often search for overload protection, phase loss safety, and temperature safeguards—this crane includes limit switches for lifting and travel, emergency stop, grounded protection, overload, phase-fault, overheating, overcurrent, overspeed, and short-circuit protection.

Customers frequently look for flexible span options—the crane’s bridge structure can be tailored to span a wide working area, and lifting height can be customized to match facility needs.

Industrial buyers often search for advanced motion control—this crane is engineered for smooth and precise operation using advanced control systems integrated into its design.

Long-term reliability is a priority for users—the crane features durable build quality and robust materials designed to withstand high usage and harsh industrial environments while minimizing maintenance.

Buyers frequently seek compliance with international standards—Sinoko’s crane is built following European design principles and can meet standards such as FEM, DIN, and ISO for quality, safety, and reliability.