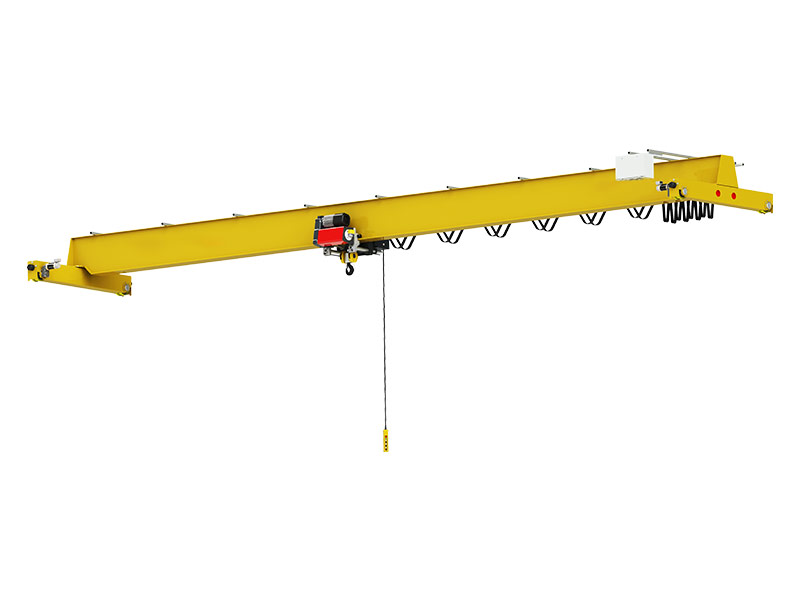

This series of EOT Crane is matched with XKD series electric hoist

1.Design is based on FEM and CMAA70 standards.

2.With optimizing design and low headroom, the crane height is greatly reduced, to achieve higher lifting height under the same plant height.

3.With optimizing design and low wheel pressure, the crane height is greatly reduced, to achieve greater lifting capacity weight under the same strength of the workshop.

4.Wheel group with adjustable structure, to prevent the rail from gnawing.

5.Crane is controlled by Three-In-One mechanism with frequency conversion, to reduce the equipment noise.

6.Overload limiter, height limiter, Stroke limiter, photoelectric limiter and other security measures are equipped according to different working conditions, crane black box with recorded analysis functions can be added based on the customer requirements.

7.Lifting capacity: 1~20 t, non-standard customized crane can be produced.

Sinokocranes Single Beam EOT Crane have many inteligent function for optional :

Cranes in Tandem

Crane interlocking feature includes

1. FIX radio system: 2×transmitter + 2×receiver.

2. Transmitters and receivers including external antennas.

3. Connection cable from transmitter and receiver to interlocking panel.

4. Relays and RC-circuit assembly and wiring to bridge panel.

5. Electrical engineering and drawings.

Synchronisation

Functionality

1. When lifting a load simultaneously with two hooks of the same crane, Hoisting Synchronization supervises and controls both hooks so that they run at exactly the same speed.

2. Also works with imbalanced loading between the hoists.

3. Synchronization of hoisting is always activated, when the operator selects common hoist mode.

Load Floating

Functionality

1. Holds the load at zero speed for a predefined time after the hoist motion stops.

2. Hoist motor provides the needed torque at the zero speed, hoist brake does not close.

3. Transition from hoisting to lowering takes place faster.

4. Starting the motion again is fast and smooth as the brake is already open.

5. The floating time can be adjusted: tipically 1~2 sec.

6. Similar Floating function is available to travelling motion.

Sway Control

Functionality

Sway Control takes the crane operator’s speed command at the control and brings the load to the required speed while minimizing sway caused by acceleration and deceleration.

Restricted Load

Functionality

Load restricted area can be in trolley movement direction or in bridge movement direction or both directions. Load restriction area can be symmetrical on both sides or single side restriction.

Common for both areas is that the restriction beginning from certain point until end of crane structure. This point is done with magnetic limit switch on runway or crane.

Inching

Functionality

1. Inching provides a way for accurate load positioning.

2. Available for hoist motion or for all three main motions.

3. Inching increments can be preset ranging from 2 to 100mm: -Each motion can have different Inching Increment

4. Each activation of the joystick moves the motion the preset Inching

Micro Speed

Functionality

1. Microspeed makes load control more precise.

2. Available for hoist motion or for all three motions.

3. Microspeed turns large joystick movement at the controls into slow and precise load movements.

4. The maximum microspeed can be preset from 1% to 99% of full motion speed.

5. Each motion can have different maximum microspeed.

6. Activated by On/Off selector in radio or pendant.

Benefits

1. Microprecisely in tight spaces, increasing safety and protecting peed helps the operator control the load.

2. Useful in heavy lifting assembly applications, where very high load positioning accuracy is needed.

Extended Speed Range(ESR)

Functionality

1. Extended Speed Range allows higher lifting and lowering speeds with partial loads.

2. With loads less than 20% of capacity, the hoist can be operated up to twice the speed at rated load.

3. Stepless ESR –The maximum allowed speed is automatically calculated based on the measured load.

Benefits

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteFAQs

A VVVF (Variable Voltage Variable Frequency) Control Overhead Traveling EOT Crane is designed for precise control of speed, acceleration, and deceleration, allowing smooth and efficient lifting and transportation of materials in industrial environments.

VVVF control improves crane performance by offering smoother start-stop motions, reducing energy consumption, minimizing wear on components, and providing better load stability. This results in improved operational efficiency and lower maintenance costs.

The main benefits include enhanced energy efficiency, reduced noise levels, better precision in load handling, longer equipment lifespan, and improved safety during lifting operations.

Yes, Sinoko's VVVF Control Overhead Traveling EOT Crane is designed to handle both light and heavy-duty applications, offering high lifting capacities, precision control, and reliability for demanding industrial operations.

Yes, Sinoko Cranes can be customized to meet specific operational requirements, including lifting capacities, control systems, and safety features, ensuring optimal performance for your facility.

The VVVF control system adjusts motor speed according to the load, ensuring that only the necessary amount of power is used for each operation, reducing energy waste and lowering overall energy costs.