Overview

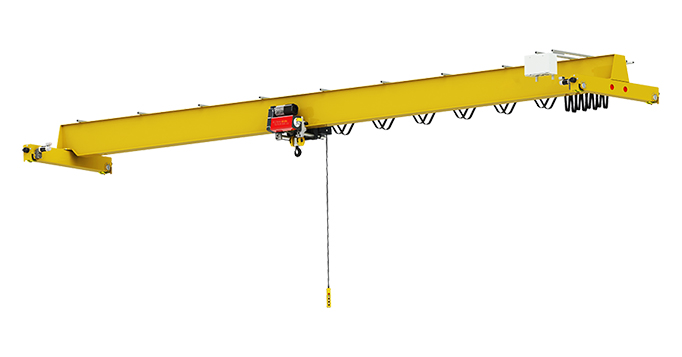

1 ton Bridge Crane is our new designed crane for the low workshop and high lifting height demands. Its technology is advanced and design is based on international standard: DIN (Germany), FEM (Europe), and ISO (International).Its variable speed can satisfy different working situation and demand.

Compared with general overhead crane (bridge crane), weight is reduced by about 15-30% of common crane, max wheel pressure is reduced by about 10-30%. which has less requirement to the workshop structure, reduce production cost. Its speed can be changable and variable speed can make the crane adjust to the different working situation and make the crane work more effciently. Its variable speed can satisfy different working situation and demand.

Features

1. Low headroom

2. Smart driving, higher efficiency

3. Stepless control trolley

4. Hardened gear

5. IP55 Protection, F/ H Insulation

6. Heavy duty motor, 60%ED rating

7. Over heating, Overloading protect

8. Electromagnetic disk brake

9. Super drum, longer rope lifetime

10. DIN 34CrMo4 hook, Class T

11. Maintenance free

Specification

| Capacity | 1 tons |

| Lift height | Max. 90 m |

| Span | 7.5~40m |

| Work duty | M3~M6 |

| Protection class | IP54/IP55 |

| Working temperature | -20~+60℃ |

As a bridge crane manufacturer and supplier, Sinoko Cranes can provide you with bridge cranes of various tonnages to fully meet your material handling needs.

Sinoko cranes have a lifting capacity of 1 ton, 2 tons, 3 tons, 5 tons, 10 tons, 15 tons, 20 tons, 25 tons and 550 tons. To meet your requirements, Sinoko Cranes can be designed according to your requirements. Contact us to get your crane with a specific tonnage.

CASE

Explore real-world project cases to see how Sinoko’s variable-speed crane solutions are delivering reliability, precision, and efficiency across various industries.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

“Variable speed” means the crane uses a Variable Frequency Drive (VFD) to smoothly adjust travel and hoist speeds on the fly—no fixed presets. This allows operators to precisely match speed with load conditions, improving control and efficiency.

Because this design is lighter—typically reducing crane weight by 15–30% and wheel pressure by 10–30% compared to common overhead cranes—it exerts less stress on building structures, potentially lowering construction or reinforcement expenses.

VFD-equipped cranes benefit from smoother starts and stops (soft control), significant energy savings by only using needed power, enhanced safety via reduced load swing, precise positioning thanks to fine speed control, and reduced mechanical wear—ultimately extending component life.

Absolutely. VFD-driven cranes minimize load swing, allow multi-axis or diagonal moves, support very precise placement for delicate or high-value loads, and smart anti-sway control. These features not only boost cycle speed but also improve operator safety and load accuracy.

By enabling soft stops and starts, VFDs limit mechanical shock to brakes, gears, motors, and structural components. This translates to lower wear and fewer replacements—especially on braking systems—and longer intervals between maintenance.

Yes. Modern VFDs often include Safe Torque Off (STO), programmable limits, dynamic braking options, fault detection, overload protection, and remote diagnostics. This makes crane systems safer, easier to monitor, and faster to troubleshoot.