Warehouse overhead crane comes in a number of different shapes and sizes to handle loads of any capacity. It can optimize the lifting work in your plant.

Features

1, Design technology from Europe, standardization and modularization of components, compact product structure, small work dead zone and high space utilization

2, The dead-weight is lighter, the wheel pressure is smaller, the space occupied by the factory is smaller, and the load-bearing requirements for the steel structure of the factory building are greatly reduced. If this factor is taken into account in the plant design phase, the investment cost of the plant can be greatly reduced.

3, In addition to adopting more advanced designs, the core components are imported or imported from Europe, which makes the equipment failure rate extremely low, and the operating costs in the later period are greatly reduced, which also effectively avoids the adverse effects caused by equipment shutdown.

4, Energy saving and environmental protection, less power.

5, The design life of the equipment is long, which increases the elimination period of the equipment and avoids waste of production capacity and resources.

6, User-friendly design, beautiful and easy to operate.

7, Special purpose, tailored to the characteristics of different industries, making the equipment more specific.

8, Highly intelligent, leading the development trend of the crane industry.

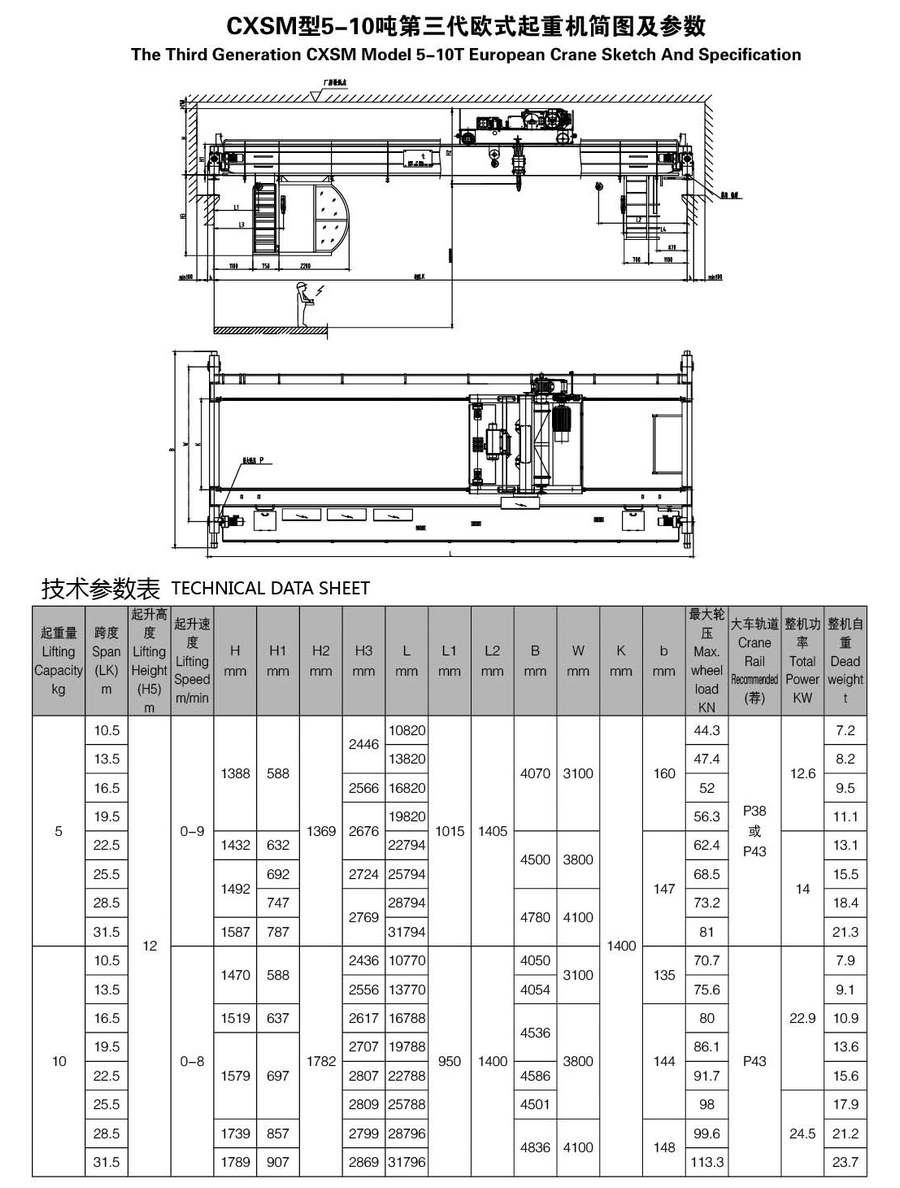

Specification

Model NO | European Type |

Condition | New |

Type | Double Girder Crane |

Span | up to 35 m |

Lifting Speed | 5/0.38 m/min |

Cross Speed | 0~30 M/Min (VVVF) |

Working Class | A5-A8 |

Origin | Henan, China |

Load Capacity | 5t to 350t |

Way to Control | Pendant Push Button / Wireless Remote Controller / Cabin |

Trademark | SINOKO CRANES |

Specification | CE, ISO |

HS Code | 8426112000 |

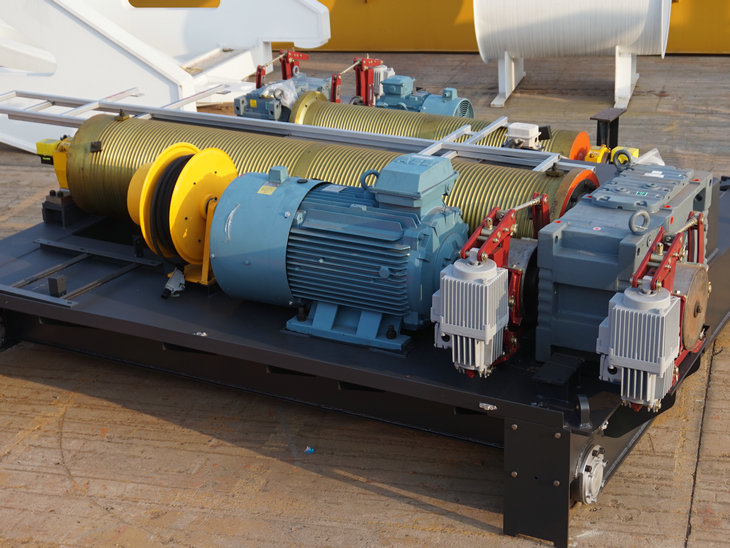

Motor | ABB Brand |

Reducer | SEW Brand |

If you're interested in our Warehouse Overhead Crane, please contact us for a quote. We'd be happy to discuss your specific requirements and provide you with a solution that meets your needs.

CASE

Discover how Sinoko Crane solutions are successfully applied across various industries worldwide. From heavy manufacturing to precision assembly, our project cases highlight the performance, reliability, and customization of our crane systems in action. Explore more crane projects to see how we can support your lifting needs.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

Sinoko’s double‑girder overhead crane uses two parallel girders to support the hoist, allowing for higher lifting capacity, greater stability, and improved hook clearance. Its compact European‑style design reduces dead weight and wheel load, making it ideal for low‑headroom workshops and boosting usable lifting height.

Sinoko’s double‑girder overhead cranes are available in capacities from as low as 5 tons up to heavy‑duty solutions approaching 100 tons or more, with spans customizable up to around 35 meters or beyond depending on the model.

Sinoko cranes support multiple control modes for flexibility and safety: pendant push‑button, wireless remote control, or operator cabin—allowing you to choose based on your operational preferences and workshop layout.

Sinoko integrates extensive safety mechanisms, including overload protection, limit switches, thermal overload and emergency stop systems, collision prevention (like laser anti‑collision), and protective braking. High‑quality components from brands like Schneider, ABB, and SEW further enhance reliability.

This crane features modular, European‑optimized design, energy‑saving drives (like VVVF speed control), lighter dead‑weight, and standardized components—reducing power consumption, simplifying maintenance, and lowering long‑term operating costs.

Yes—Sinoko's cranes comply with international standards such as CE, ISO, FEM, and DIN. Many models carry certifications ensuring they meet rigorous safety, health, and environmental requirements across global markets.