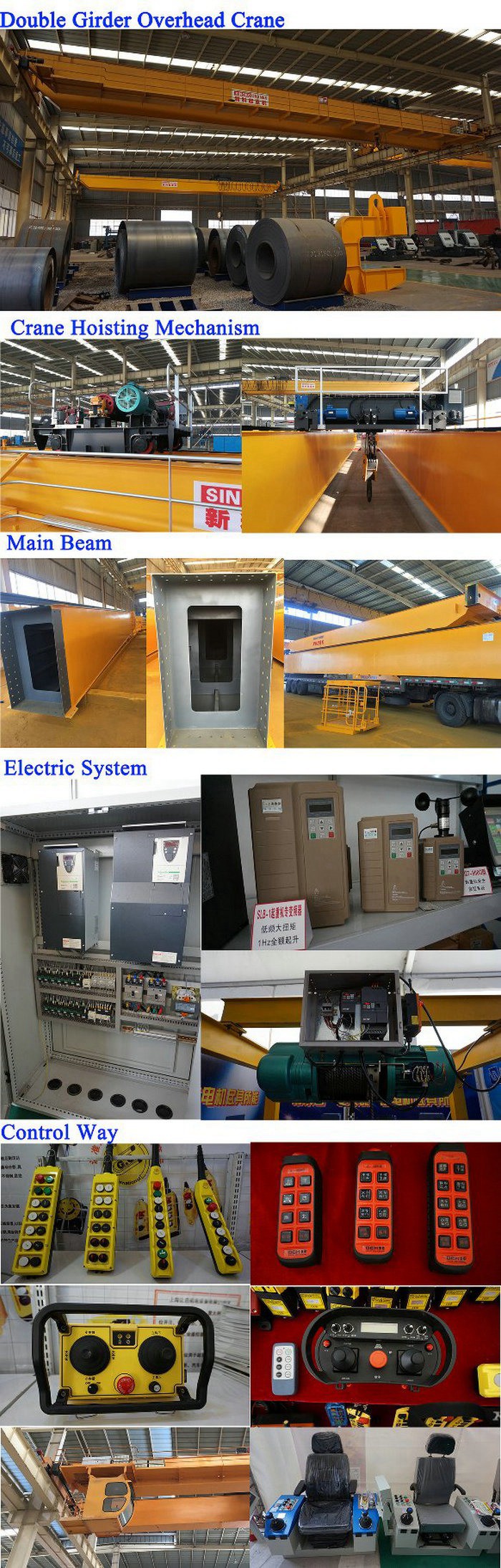

Electric Overhead Travelling Crane With Hook is composed by the bridge frame, crab, trolley travelling mechanism, electrical equipment. This crane is suitable for the workshops, good yards and warehouses of the departments of stations, ports, industrial and mining enterprises, lifting, transporting, loading and unloading all kinds of materials in a fixed span. Depending on the different using frequency, it can be divided into A5, A6,A7 class. The maximum capacity can be up to 450 ton.

Features

Specification

| Lifting Capacity T | 5 | 10 | 16/3.2 | 20/5.0 | 25/5.0 | 32/5.0 | Oct-50 | |||

| Span M | 10.5-31.5 | |||||||||

| Lifting height M | Main Hook | 16 | 16 | 16 | 12 | 12/11.0 | 16 | 12 | ||

| Aux Hook | 18 | 11 | 14/13 | 18 | 16 | |||||

| Speed M/min | hoist | Main hook | A5 | 12.5 | 8.5 | 7.9 | 7.2 | 7.3 | 7.8 | 5.9 |

| A6 | 15.5 | 13.3 | 13 | 9.7 | 9.8 | 9.5 | 7.8 | |||

| Aux hook | 14.5 | 12.7 | 12.7 | 19.5 | 13.2 | |||||

| Trolley travelling | 37.2 | 43.8 | 44.6 | 44.6 | 37 | 42.4 | 38.5 | |||

| Bridge travelling | A5 | 89.8 /92.3 | 89.8-91.9 | 84.7-87.6 | 84.7/ 87.6 | 85.5/88 | 74.2-87.6 | 74.6 | ||

| A6 | 116.2/ 117.4 | 112.5-116.8 | 112.5 | 112.5/ 101.4 | 112/ 101.4 | 86.8-101.4 | 87.3 | |||

| Weight Kg | Trolley | A5 | 2126 | 3424 | 6227 | 6856 | 7185 | 10877 | 15425 | |

| A6 | 2224 | 3562 | 6427 | 7180 | 7856 | 11652 | 15765 | |||

| Total Weight | A5 | 12715-31405 | 14270-34405 | 19128-39428 | 19947-41497 | 20795-42796 | 26901-52748 | 35317-64880 | ||

| A6 | 12991-31596 | 14719-34699 | 20045-41315 | 20984-44225 | 22632-16324 | 28061-55272 | 36075-67242 | |||

| Max Wheel Load KN | A5 | 74-125 | 102-160 | 141-205 | 163-231 | 185-255 | 237-327 | 333-450 | ||

| A6 | 75-126 | 104-162 | 145-211 | 167-239 | 189-263 | 242-335 | 336-457 | |||

| Rail recommended | Trolley | 15kg/m | 43kg/m | |||||||

| Bridge | 43kg/m | QU70 | QU80 | |||||||

| Power Source | 380V 50HZ 3Phase | |||||||||

CASE

Want to see how our overhead cranes perform in real industrial settings? Explore Sinoko Crane’s project cases across workshops, warehouses, and heavy-duty sites to discover how we deliver safe, efficient, and customized lifting solutions for clients around the world.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

This crane supports a broad range—from 5 tons up to 500 tons—with spans between 10.5 m and 35 m, and a maximum lifting height of approximately 18 m. It’s built to serve both indoor workshops and outdoor yards effectively.

The crane is available in duty classes A5 and A6, with potential for A7 depending on usage frequency. It comes CE- and ISO-certified, and enjoys reliable global support through overseas service centers and field engineers.

Safety features include overload protection, thermal protection for the main lifting motor, latches on hooks, rubber buffers, earthing protection, emergency stop switches, and a laser anti-collision system—all designed to ensure operational precision and safety.

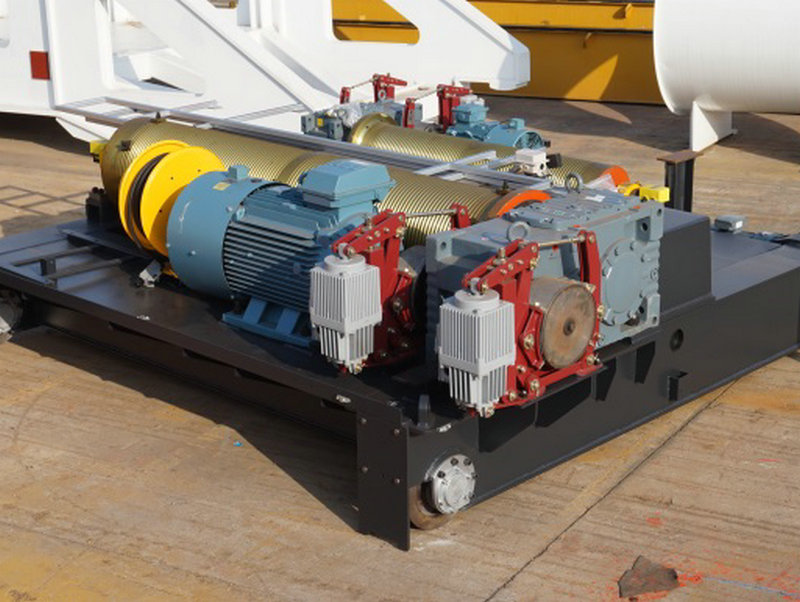

All major sub-assemblies are tested before assembly, and the crane incorporates a robust bridge frame, trolley, crab mechanism, and electrical systems—optimized for ease of maintenance and long-term performance.

Yes—this model works reliably in both indoor workshop environments and outdoor yards, as well as across industrial, mining, port, and station settings, providing versatile material handling solutions.

The crane runs on standard 380 V 50 Hz three-phase power. Recommended rails include 43 kg/m rails (QU70/QU80) for bridge travel and 15 kg/m or 43 kg/m rails for the trolley, depending on the model and load class.