1. Complete sealing structure and good moisture resistance;

2. Optimized design with reasonable structure, light weight, large suction and low energy consumption;

3. Easy to install, operate and maintain.

Features

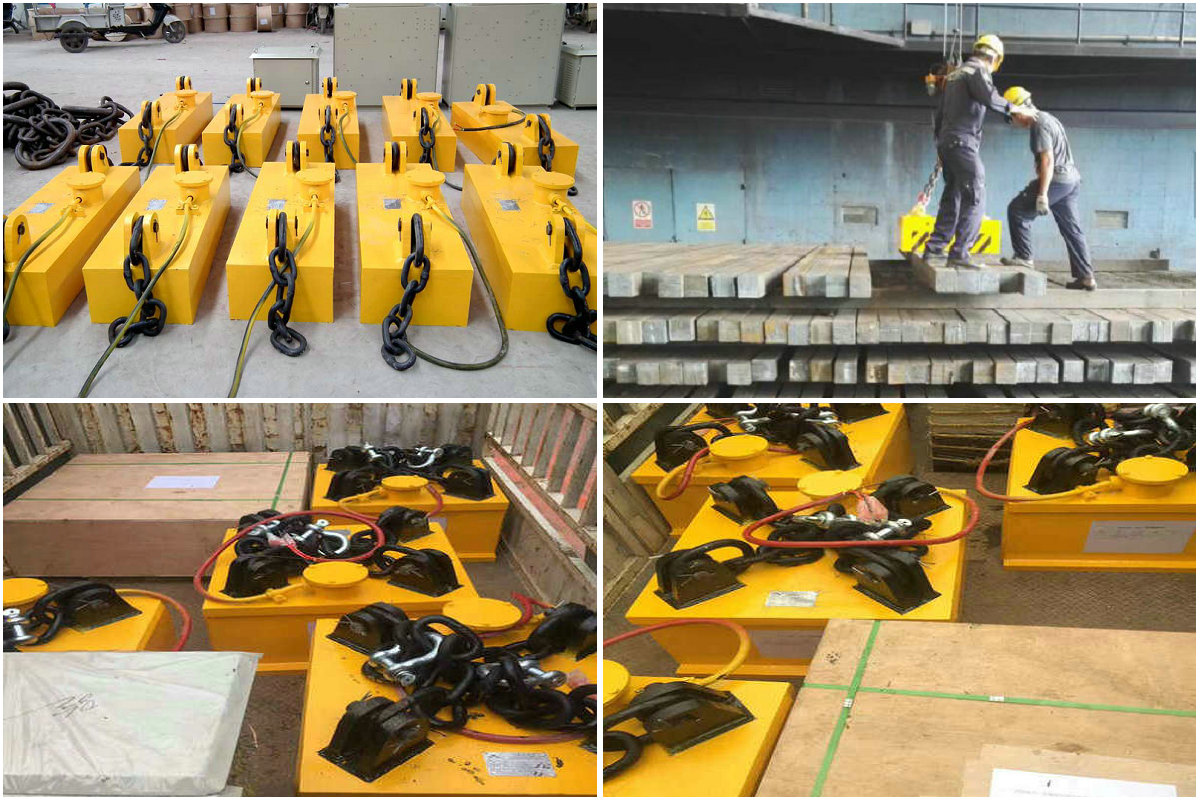

Rectangular Lifting Magnet is of robust cast and bolted or fabricated construction designed for handling solid billet, steel ingot and gives efficient and economical performance in the most arduous service condition.

We will provide you with comfortable services.

1.Trade manager is 24 hours online for your service.

2.Our technical department can make specific designs to meet various king of customers’ requirements for magnetic lifting and clamping operation.

3.OEM service is available.

4. We will go back to you in 12 hours.

5. Any question in installation and operation, we will reply in 24 hours.

6. If the product can not meet your requirement or has any problem in quality , the product can be changed or returned if it is necessary.

7.We will offer the design, product pictures and other technist data you need.

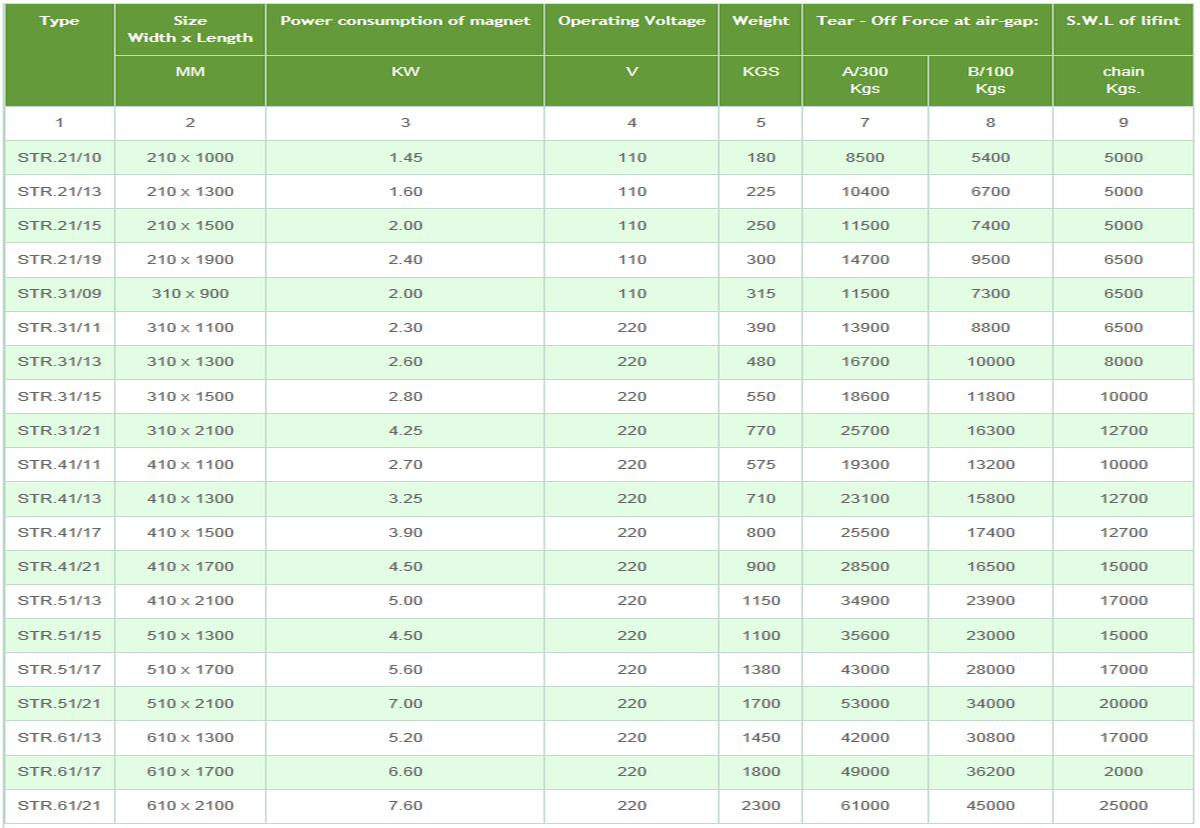

Specification

CASE

Explore case studies from clients across steel mills, scrap yards, and heavy industrial sites. Discover how Sinoko Crane delivers durable, corrosion-resistant lifting solutions tailored to challenging environments and demanding material handling needs.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuotePakistan Scrap Steel Dumping Container Gantry Crane Project Case

The Sinoko crane, leveraging years of experience and outstanding technology, designed a container gantry crane for customers, successfully solving the problem of transporting scrap steel for them.

Learn More Get a QuoteFAQs

This lifting magnet is engineered with a fully sealed housing and anti-corrosion materials that resist moisture, protecting sensitive components from rust and deterioration in demanding industrial settings such as scrap yards or foundries.

Designed to operate reliably from room temperature up to high-temperature contexts, certain models use thermal-insulated coils to safely lift hot materials—extending usable range beyond 600 °C.

Available in multiple rectangular designs, these magnets are optimized for handling heavy scrap, ingots, steel balls, and other bulk metal forms, with varying magnetic circuit configurations to suit different steel types and operational needs.

Thanks to computer-optimized structural design and efficient excitation coils, these magnets achieve a high weight-to-lift ratio while minimizing power draw—ensuring performance and energy savings.

Engineered for practical usability, the magnet features a robust welded structure, durable materials like a manganese-steel base plate, and modular design—providing easy installation, simple operation, and low upkeep.

Especially effective in scrap handling, foundries, and steel processing, this magnet enhances material transfer efficiency and performance in corrosive, dusty, or high-temperature environments—making it a trusted choice for heavy industrial applications.