Overview:

Electromagnetic Scrap Magnet for EOT Crane Types For Option:

1.1 Normal temperature type (DC-220V TD-60%): for lifting normal temperature steel scraps.

1.2 High temperature type (DC-220V TD-60%): for lifting high temperature steel scraps or lift steel scraps in high temperature environment. It is specially for used to lift steel scraps into furnace to make steel in steel plants. This magnet can handle the steel scraps under the temperature of 650°C.

1.3 High frequency type (DC-220V TD-75%): for lifting normal temperature steel scraps in high frequency use. It can be operated more efficiently and frequently since the duty cycle is up to 75%.

The over-excitation control system (DC350/DC290V/DC-200V) is also available for large size magnet of this kind, in order to quicken the current, increasing speed and to exert stronger lifting capacity.

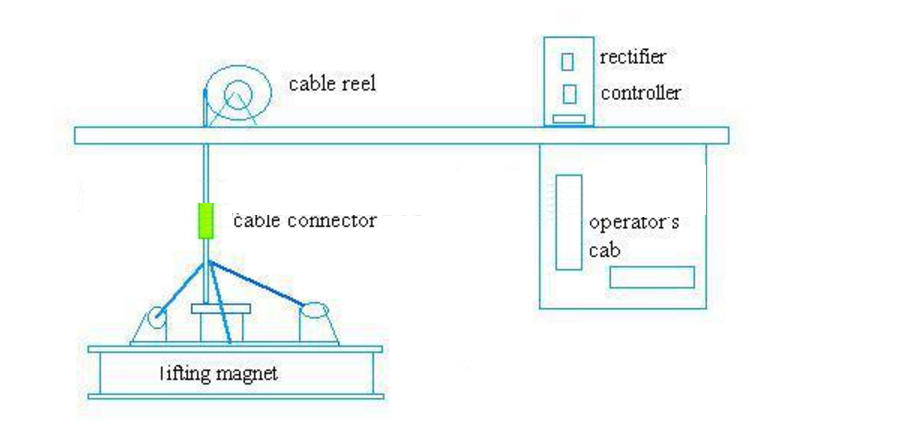

Electromagnetic Scrap Magnet Installation Pattern:

2.1 Used with crane:

Complete set of this equipment: MW5 Scraps Circular Magnet Lifting (for crane), Rectifying Control Equipment, Cable Reel and Cable Connector. Simple and easy to installation. We can send installation video to guide your side.

2.2 Used with excavator:

Complete set of this equipment: MW5 Scraps Circular Magnet Lifting (for excavator), Control Equipment and Generator Set.

Features

a. It adopts a special magnetic circuit design which has large air space and magnetism density. It is made of aluminum wire and the coil protection plate is made of the rolled high Mn steel plate that has good performance of wear-resistance and heat-proof. It also has the characteristics of light weight, low power consumption, high lifting capacity and long serving life.

b. This series has fine insulation structure. The insulation treatments adopt the vacuum drying & glue filling, which has improved the electrical and mechanical performance of the coils .The insulation grade can reach class special C.

c. It generally adopts the control mode of constant voltage. It can further improve the lifting capacity if changing to adopt the control mode of over excitation.

d. With simple structure reliability, it is suitable for working with all kinds of lifting equipments.

Scrap Magnet Overall Dimension Drawing and Specification

| Model | Lifting capacity (kg) | ||

| (cold/hot state) | |||

| Steel ball | Steel ingot | turnings | |

| MW5-50L/1 | 1200 | 220/130 | 80/65 |

| MW5-60L/1 | 2000 | 290/170 | 95/80 |

| MW5-70L/1 | 2500 | 380/200 | 120/100 |

| MW5-80L/1 | 3000 | 480/250 | 150/130 |

| MW5-90L/1 | 4500 | 600/400 | 250/200 |

| MW5-110L/1 | 6500 | 1000/800 | 450/400 |

| MW5-120L/1 | 7500 | 1300/1000 | 650/500 |

| MW5-130L/1 | 8500 | 1400/1100 | 700/600 |

| MW5-150L/1 | 11000 | 1900/1500 | 1100/900 |

| MW5-165L/1 | 12500 | 2300/1800 | 1300/1100 |

| MW5-180L/1 | 14500 | 2750/1100 | 1600/1350 |

| MW5-210L/1 | 21000 | 3500/2800 | 2200/1850 |

| MW5-240L/1 | 26000 | 4800/3800 | 2850/2250 |

| MW5-260L/1 | 30000 | 6100/4900 | 3600/3850 |

| MW5-280L/1 | 34000 | 7100/5700 | 4450/3400 |

| MW5-300L/1 | 39000 | 8350/6700 | 5150/4100 |

FAQs

It’s a high-performance electromagnetic scrap magnet designed for use with EOT (Electric Overhead Traveling) cranes, ideal for lifting and handling scrap metal.

The MW5 magnet is designed for lifting ferrous materials, such as scrap metal, steel plates, and iron debris.

Yes, the MW5 is specifically designed for use with EOT cranes, but it can also be adapted for other crane types based on your lifting needs.

The MW5 magnet can lift heavy loads, with varying capacities depending on the specific model. Please refer to the product page for detailed load capacity information.

Yes, the MW5 is built to withstand high temperatures, making it ideal for use in scrap yards or recycling facilities where materials may be heated.

Regular inspection and cleaning are essential. Follow the detailed maintenance instructions provided in the user manual for optimal performance and longevity.