With a lifting capacity ranging from 0.5 to 16 tons, this crane can handle a wide range of loads, making it suitable for various applications. Its span ranges from 7.5 to 25 meters, ensuring ample coverage across your workspace. The crane operates at working levels of A4 to A6, making it well-suited for both light-duty and heavy-duty tasks.

The SG Monorail Crane consists of several key components that work together to ensure its smooth and efficient operation. Here are the main components of the crane:

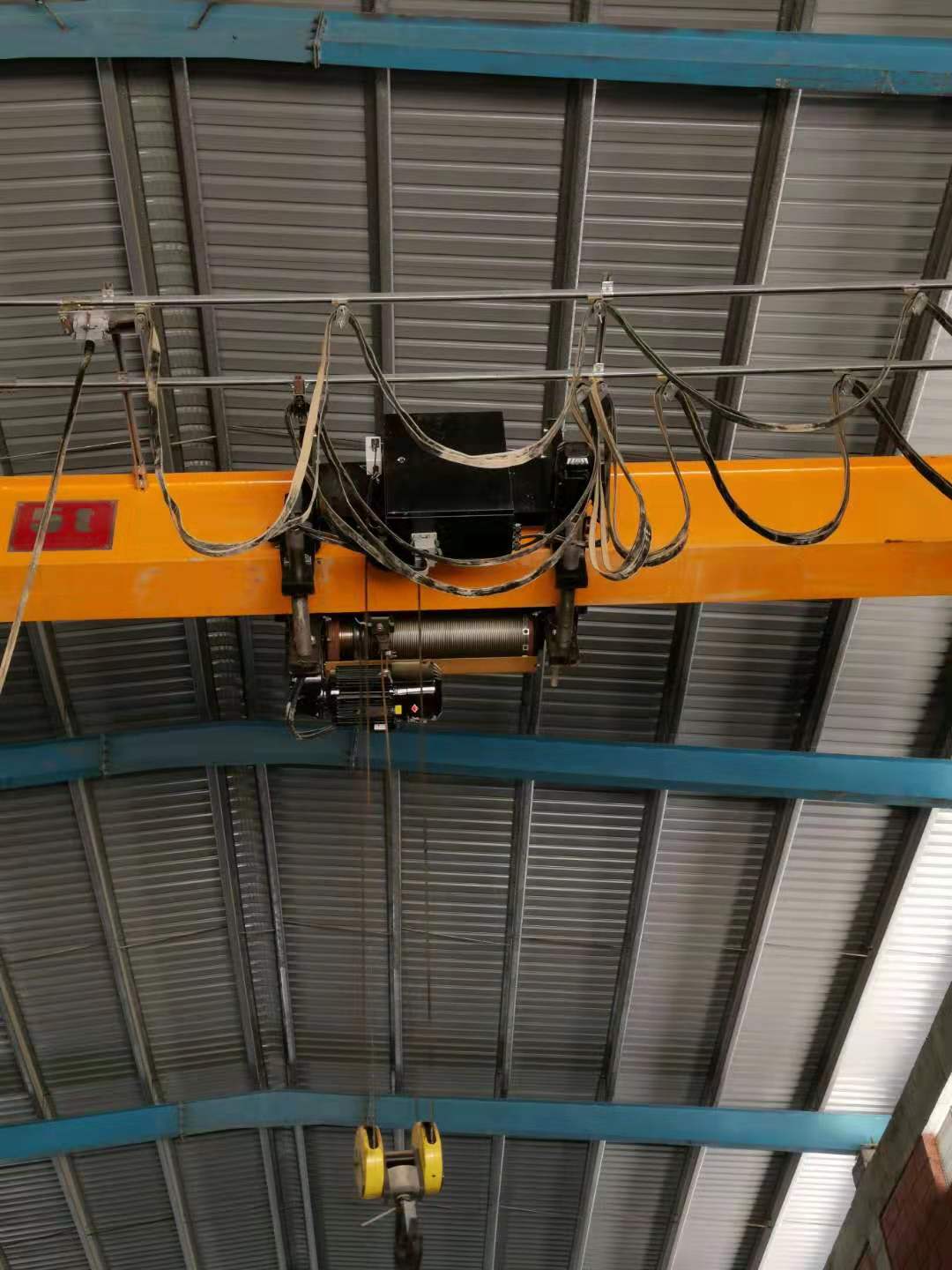

Girder: The girder is the horizontal beam that supports the lifting mechanism and the trolley. It provides stability and strength to the crane structure. In the case of the SG Monorail Crane, it is a single girder design.

End Carriages: The end carriages are located at each end of the girder and house the wheels that allow the crane to travel along the rail. They provide support and stability while enabling smooth movement of the crane.

Lifting Mechanism: The lifting mechanism consists of a hoist that is responsible for raising and lowering the load. It is typically equipped with a wire rope or chain, along with a motor and braking system, to ensure safe and precise lifting operations.

Trolley: The trolley is the mechanism that runs along the girder, allowing horizontal movement of the load. It is mounted on wheels and is driven by a motor, enabling the crane to position the load accurately.

Control System: The control system of the SG Monorail Crane comprises various components, including a control panel, electrical wiring, and control buttons. It enables the operator to control the crane's movements, lifting, and traversing operations, ensuring safe and efficient material handling.

Safety Features: The crane is equipped with a range of safety features to protect both the operator and the load. These may include limit switches to prevent over-travel, emergency stop buttons, overload protection systems, and safety buffers, among others.

These components work in harmony to provide reliable and precise material handling capabilities, allowing the SG Monorail Crane to perform its tasks efficiently and safely.

|  |

Lifting Capacity: With a lifting capacity ranging from 0.5 to 16 tons, the SG Monorail Crane caters to a wide range of material handling needs. From lightweight components to heavy loads, this crane has the strength and versatility to handle it all.

Span: The crane boasts a span of 7.5 to 25 meters, providing ample coverage across your workspace. Its impressive span ensures maximum efficiency and maneuverability, allowing you to transport goods with ease and precision.

Working Level: Operating at working levels of A4 to A6, the SG Monorail Crane guarantees exceptional performance in demanding environments. Whether you're dealing with light-duty tasks or heavy-duty operations, this crane is up to the challenge.

Temperature and Humidity Tolerance: Designed to withstand varying conditions, this crane operates flawlessly within a temperature range of -10°C to +50°C. Additionally, its components are built to resist humidity levels of up to 90%HR, ensuring consistent performance regardless of the environmental factors.

Advantages of SG Monorail Crane

Compact Design: The SG Monorail Crane is a compact and lightweight rail crane, making it an ideal choice for facilities with limited space. Its streamlined design maximizes efficiency without compromising on lifting capacity, allowing you to optimize your workspace effectively.

High-Quality Construction: Crafted with meticulous attention to detail, this crane is built to last. Its construction adheres to European and Chinese standards, ensuring durability, reliability, and long-term performance. You can trust the SG Monorail Crane to withstand the test of time and provide exceptional value for your investment.