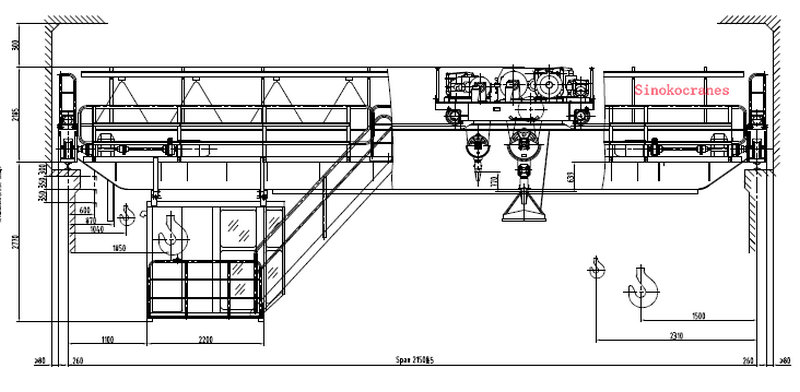

Garbage grab bucket EOT crane girder is of welded girder construction. This result in lower dead weight with a high degree of vertical and horizontal rigidity and small wheel loads being transmitted to the crane runway. The grab bucket crane is a special kind of overhead crane which can be used to grab steel scraps, sludge, sand, limestones, garbage and so on. The EOT crane also can assembly with magnets for lifting steel materials, like steel scraps, steel billets, steel rebar. The working class is heavy duty.

Features

Grab Bucket Crane General Features

1. Crane material: Q235,Q345B/Q345D

2. No-welding joint strong box type, by machine hand, strong and beautiful.

3. Wheels are vacuum casting by ourselves, intermediate frequency quenching

4. Wheels, wire rope, drum, gears, coupling are manufactured by our CNC machines.

5. ABB, SEW motor or Huanghe explosion-proof, top quality in the world.

6. Electrical equipment: Siemens or Schneider brand.

7. Control method: Cabin control, wireless remote control or pendant control, you can choose one of them (According to your demands).

Grab Crane Safety Features

1. Overload protection device

2. Top quality long time bearing polyurethane materials buffer

3. Crane traveling limit switch

4. Voltage lower protection function

5. Emergency stop system

6. Lifting height limit device

Specification

Lifting Capacity: 5t~50t

Span: 6m to 45m

Lifting height: 5m to 40 m

Working duty: A6 (M6), A7 (M7), A8 (M8)

CE, ISO certificate, Top quality

Various Types of Grab Bucket Crane

grab bucket cranes come in various types, each designed to handle different materials with specific characteristics, including varying volume densities. The weight of the grab bucket can significantly differ based on its design, material, and intended use. these cranes are commonly used in industries such as shipping, construction, and mining where large quantities of loose materials need to be moved efficiently.

| Type of Grab Bucket Crane | Description | Ideal Materials |

| Single Rope Grab Bucket Crane | Uses a single rope to control grab bucket operation. | Sand, Gravel, Agricultural Products |

| Four Rope Grab Bucket Crane | Operates with four ropes, providing stability and precise control. | Iron Ore, Coal, Minerals |

| Clamshell Grab Bucket Crane | Features a two-piece grab bucket resembling a clamshell for digging into materials. | Sand, Gravel, Dredged Sediments |

| Orange Peel Grab Bucket Crane | Equipped with hinged jaws resembling an orange peel, ideal for handling scrap metal and rocks. | Scrap Metal, Rocks, Irregularly Shaped Materials |

| Electro-Hydraulic Grab Bucket Crane | Uses an electro-hydraulic system for precise control over grab bucket movements. | Various Bulk Materials |

| Radio-Controlled Grab Bucket Crane | Operated remotely via radio control, enhancing safety and flexibility. | Hazardous Materials, Toxic Substances, Various Bulk Materials |

If you're interested in high-quality crane solutions, consider exploring Sinoko Cranes. Sinokocranes offer a wide range of crane products tailored to various industrial needs. Whether you require a single rope grab bucket crane for handling lighter materials or a four rope grab bucket crane for heavy-duty applications, Sinoko Cranes has you covered.

CASE

Explore project case studies showcasing how Sinoko Crane solutions are applied across waste management, recycling, steel production, and more. Discover how our customized lifting systems deliver efficiency, safety, and durability in demanding industrial applications.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

This crane excels at gripping and lifting bulky, loose materials—whether it’s garbage, steel scrap, sludge, sand, lime, or limestone—making it highly versatile for heavy-duty waste handling and material recovery operations.

The crane offers lifting capacities from 5 t up to 50 t, spans ranging from 6 m to 45 m, and lifting heights between 5 m to 40 m. It supports heavy-duty working classes such as A6 (M6), A7 (M7), and A8 (M8), satisfying rigorous industrial demands.

Its girder features a welded box-type design—produced via machining rather than welding joints—to achieve high rigidity while keeping deadweight low. This also notably reduces the load transmitted to the runway.

Key components include ABB or SEW motors (or explosion-proof models from Huanghe) and electrical systems from Siemens or Schneider. Safety features include overload protection, buffer bearings made with durable polyurethane, travel limit switches, emergency stop capabilities, voltage low protection, and lifting limit devices.

Operators can choose from multiple control methods—cabin control, wireless remote control, or pendant control—allowing for flexible operation depending on site conditions and safety requirements.

This crane is a strong solution for sectors like steel mills, waste incineration plants, recycling yards, ports, construction sites, and other heavy-duty environments where efficient handling of loose bulk materials is essential. Its robust design and component quality make it well-suited to demanding industrial settings.