Overview

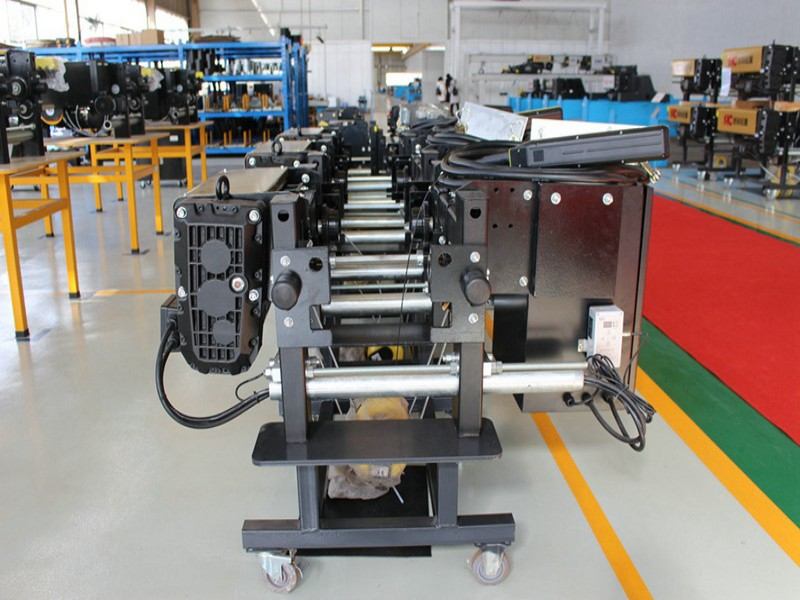

Our FEM Class Wire Rope Electric Hoist is a high-performance lifting solution, crafted with meticulous attention to detail. This type of hoist is characterised by its robust wire rope, engineered for superior strength and resilience. The model is designed to incorporate advanced technology, and all key parts are built in accordance with the FEM standard, reflecting our commitment to maintaining the highest level of quality and precision.

Features

The FEM Class Wire Rope Electric Hoist offers an array of outstanding features that make it a preferred choice among high-end users:

High Reliability: The hoist is crafted with precision, ensuring long-lasting performance and minimal downtime.

Durability: The robust design and high-quality materials provide unmatched durability, allowing the hoist to withstand rigorous use.

Free Maintenance: As a testament to our confidence in this product, Sinokocranes offers free maintenance, emphasizing our commitment to customer satisfaction.

Advanced Technology: Our design incorporates the most advanced technology, making the hoist more efficient and easy to operate.

Sinokocranes FEM Class Electric Wire Rope Hoist Advantage | |

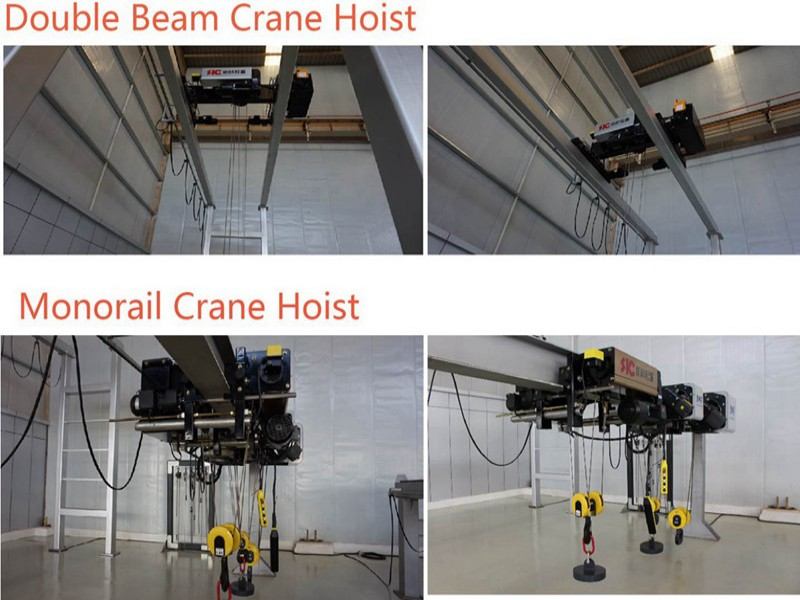

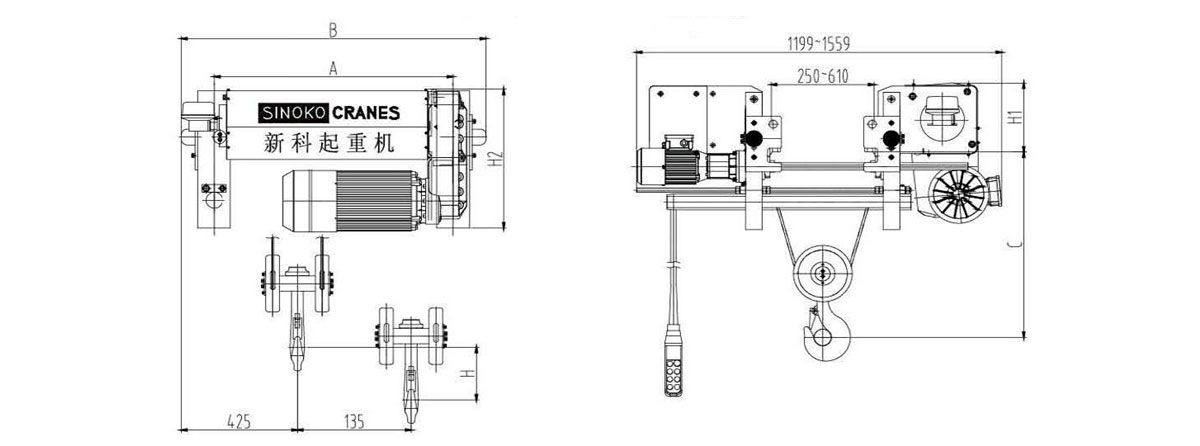

| First, high efficiency, maximize the use of space The leading technical design ensures the maximum size of product optimization, and the compact structure ensures high performance. In the same factory and work area, the application of sinokocranes wire rope hoist can cover a wider range and reduce blind spots. If the design of the product family of sinokocrane is used during the design phase of the plant, the height of the plant can be greatly reduced, saving customers investment and increasing efficiency. |

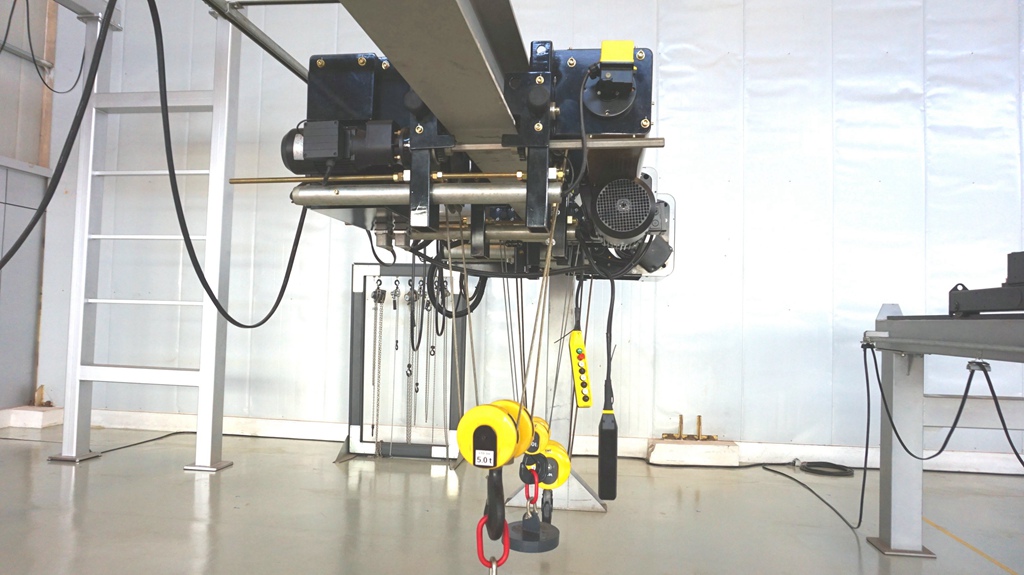

| Second, accurate positioning, efficient operation, improve logistics efficiency The high-quality lifting drive ensures safe, smooth and efficient operation. The compact structure design ensures the smallest offset of the hook. The lifting provides two-speed (inverter selectable). The trolleys are standard in frequency conversion and ensure lifting. The efficient operation of the equipment and the improvement of the efficiency of the workshop logistics ensure that the customer's various work plans are executed as scheduled. |

Third, safe and reliable, operation monitoring, easy maintenance Sinokocranes lifting proprietary technology has multiple protection functions, the device ensures the safe and reliable operation of the crane, and its operation monitoring unit can record detailed information on the operation status of the electric hoist, motor operation status and safe working cycle, and provide caveat. All records can provide data for maintenance, understand the root cause of the problem, and make the crane maintenance schedule more timely and reasonable. | |

| Fourth, modular design, low maintenance costs, complete spare parts service The concept of modular design has always penetrated the design of the entire product, ensuring the standard and interchangeability of components, greatly improving product quality and reducing the maintenance cost of the product. All of our companys product lines have a complete spare parts inventory, the company has a professional service team, to ensure that customers provide timely after-sales service, to solve customer worries after the purchase of equipment. |

Specification

| Capacity (kg) | Lifting Height(H) m | Lifting speed m/min | Traveling speed m/min | Max. Wheel load KN | Total Power KW | Dead weight Kg |

| 3200 | 6 | 12 5/0.83 Double Speed | 20/5 VVVF Double Speed | 8.5 | 3.84 | 363 |

| 9 | 8.7 | 379 | ||||

| 12 | 9 | 395 | ||||

| 15 | 9.2 | 411 | ||||

| 18 | 9.4 | 424 | ||||

| 5000 | 6 | 12 5/0.83 Double Speed | 20/5 VVVF Double Speed | 13.5 | 5.54 | 468 |

| 9 | 13.7 | 502 | ||||

| 12 | 13.8 | 535 | ||||

| 15 | 14 | 569 | ||||

| 18 | 14.2 | 636 | ||||

| 10000 | 6 | 12 5/0.83 Double Speed | 20/5 VVVF Double Speed | 26.3 | 10.46 | 562 |

| 9 | 26.5 | 601 | ||||

| 12 | 26.8 | 637 | ||||

| 15 | 27.2 | 675 | ||||

| 18 | 27.5 | 711 |

Application

The FEM Class Wire Rope Electric Hoist from Sinokocranes is suitable for a wide range of applications. It is ideal for industries requiring high-performance hoisting solutions, such as construction, manufacturing, warehousing, and logistics, among others. Its superior design and robust build make it suitable for the most demanding conditions, offering consistent performance and reliability.

Why Sinokocranes?

At Sinokocranes, we are more than just a supplier; we are a partner in your success. Our deep-rooted focus on technological innovation in the field of FEM standard electric wire rope hoist has been a driving force in our journey over the years. We believe in not just meeting, but exceeding customer expectations, delivering more reliable, more durable, and maintenance-free products. Our FEM Class Wire Rope Electric Hoist is a prime example of this commitment.

Choose Sinokocranes. Choose excellence. Choose reliability.

CASE

Explore more crane project cases to see how Sinoko solutions deliver reliable performance across various industries.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

The FEM‑2m designation indicates a heavy-duty classification with a long service life—typically around 1,600 hours of use under heavy load conditions—making it suitable for demanding industrial environments.

Thanks to its compact, optimized structure, the hoist delivers high performance in minimal space. It maximizes hook reach and reduces plant height requirements, improving logistics and reducing dead zones.

Equipped with inverter-selectable dual-speed lifting, the hoist enables both precise positioning and rapid lifting, increasing accuracy and overall handling efficiency.

The hoist includes multiple protective functions and an operation monitoring system that logs motor and work-cycle data. These insights support preventative maintenance and ensure reliability.

The hoist is built with a modular design philosophy, ensuring parts are interchangeable. This reduces downtime, lowers maintenance costs, and supports Sinoko’s robust spare-parts and service infrastructure.

3,200 kg model: Features dual-speed lifting (12 / 0.83 m/min) and VVVF-controlled traveling speed (~20 m/min), delivering smooth and efficient performance.

5,000 kg model: Offers dual-speed lifting (13.5 / 0.83 m/min) and similar VVVF travel speeds, catering to heavier loads with precision and control.