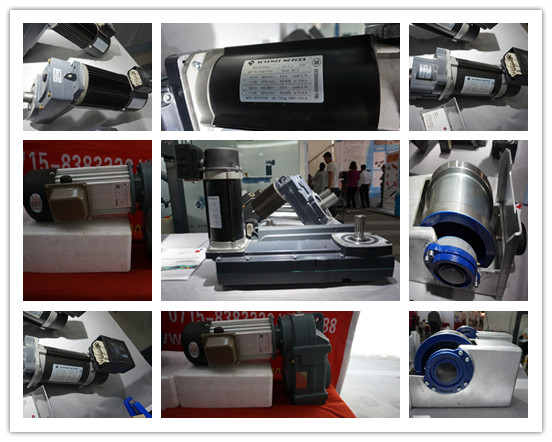

There in One Gear Motor Driving System Structures and Scope of Supply:

1. The reducer consists of gears, axles, domestic bearings, box shells, bolts and pads.

2. The motor is composed of stator, bearing, rotor, shell, brake, heavy load connector (aviation plug).

3. The brake is divided into electromagnetic brake and side magnetic brake.

Features

Self-Developed There in One Driving System Features from Sinokocranes:

1. The surface is chemically treated with strong corrosion resistance.

2. The unique electromagnetic design reduces the shaft current and improves the service life of the bearing.

3. 5-120HZ continuously variable transmission, low speed operation torque is smooth, no crawling phenomenon.

4. The high heat resistant composite enamel round copper wire has reliable winding performance and long service life.

5. The use of high-performance brakes, life can reach 1 million 500 thousand times.

6. Import bearings with international brands to ensure service life.

7. Standard thermistor and heat protection.

8. Standard heavy duty connector plug, quick connection, high safety.

9. Ambient temperature -15 ~ +40 C

10. Relative humidity 90%

11. Working system S3-40%

12. Insulation grade F/H

13. Protection level IP55

14. Three phase AC power supply

Specification

Motor Model | MF115S4/MB/TF | MF115M4a/MB/TF | MF115M4b/MB/TF | MF115L4/EB/TF | MF130M4/EB/TF | MF130l4/EB/TF | MF130L2/EB/TF | |||||||

Working Voltage V | 380-415 | 440-480 | 380-415 | 440-480 | 380-415 | 440-480 | 380-415 | 440-415 | 380-415 | 440-480 | 380-415 | 440-480 | 380-415 | |

Power KW | 0.3 | 0.37 | 0.45 | 0.55 | 0.65 | 0.75 | 1.1 | 1.1 | 1.5 | 1.8 | 2.2 | 2.5 | 3 | |

Rotating Speed pm | 2855 | 3430 | 2850 | 3440 | 2800 | 3360 | 2770 | 3370 | 2850 | 3430 | 2860 | 3460 | 4460 | |

Current A | 1.2 | 1.2 | 1.8 | 1.8 | 2.1 | 2.1 | 3 | 2.9 | 3.9 | 3.9 | 6.9 | 6.5 | 7.9 | |

Motor Voltage V | 400 | 460 | 400 | 460 | 400 | 460 | 400 | 460 | 400 | 460 | 400 | 460 | 400 | |

Frequency HZ | 100 | 120 | 100 | 120 | 100 | 120 | 100 | 120 | 100 | 120 | 100 | 120 | 80 | |

Power Ratio | 0.57 | 0.59 | 0.52 | 0.53 | 0.61 | 0.61 | 0.73 | 0.74 | 0.75 | 0.76 | 0.66 | 0.68 | 0.78 | |

Brake Type | Compact | Compact | Compact | DC | DC | DC | 直流 | |||||||

Brake Torque m | 2 | 2 | 2 | 2 | 2 | 2 | 4 | 4 | 16 | 16 | 16 | 16 | 16 | |

Start Torque m | 3 | 2.9 | 7.2 | 7.1 | 7.2 | 7.1 | 10.5 | 10.4 | 13.5 | 12.7 | 23.5 | 21.6 | 16.5 | |

Start Current A | 4.2 | 4.3 | 8.2 | 8.5 | 8.2 | 8.5 | 12.9 | 12.6 | 19.3 | 19.4 | 35 | 34 | 32 | |

Max Moment m | 3 | 2.9 | 7.2 | 7.1 | 7.2 | 7.1 | 11 | 10.8 | 17.5 | 16.5 | 25 | 23 | 17 | |

Empty Load Current A | 1 | 1 | 1.6 | 1.6 | 1.6 | 1.6 | 2.2 | 2 | 2.5 | 2.3 | 5.4 | 4.9 | 6 | |

Moment of inertia Kgm² | 0.0004 | 0.0007 | 0.0007 | 0.0006 | 0.0012 | 0.0012 | 0.0012 | |||||||

Mechanical efficiency | 0.65 | 0.65 | 0.73 | 0.74 | 0.73 | 0.74 | 0.74 | 0.76 | 0.75 | 0.76 | 0.73 | 0.75 | 0.74 | |

Weight kg | 4.9 | 4.9 | 6.8 | 6.8 | 6.8 | 6.8 | 7.8 | 7.8 | 13 | 13 | 13 | 13 | ||

Upgrade your lifting equipment with our advanced gear motor. Experience smoother operation, higher bearing capacity, and enhanced performance. Contact us now to elevate your overhead cranes, gantry cranes, trolleys, and electric hoists with our reliable gear motor solution.

CASE

At Sinoko Crane, our components are trusted by clients worldwide for their durability, efficiency, and engineering precision. To help you better understand how our solutions are applied in real industrial settings, we’ve compiled a selection of project case studies. These examples highlight how our end trucks, cranes, and systems are integrated into various operations to improve productivity and ensure safe, reliable performance.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

A: The “there‑in‑one” system integrates motor, gearbox, and brake into a single compact module for the end truck, resulting in smoother travel, improved assembly efficiency, and reduced maintenance—and enhancing overall operating reliability.

A: Yes. This driving configuration is compatible with both single‑girder and double‑girder overhead cranes, offering versatile application across a wide range of capacities and structural types.

A: Modular box‑type construction makes the end truck lighter, more durable, easier to install, and simplifies customization. This design also helps lower production costs while maintaining structural integrity

A: Standard safety features include overload protection, travel‑limit switches, voltage‑loss protection, emergency stop capability, sound/light alarms, and high‑quality buffers—ensuring safer crane operation.

A: Certainly. Sinoko offers customizable end trucks with wheel diameters ranging approximately from 150 mm to 500 mm based on load requirements, and connection to the crane girder can be tailored via bolt holes or welding as needed.

A: The integrated, compact driving module and rugged components (like forged wheels and modular structure) reduce part complexity, minimize maintenance time, and extend service life—translating to lower long-term operational costs.