Overview:

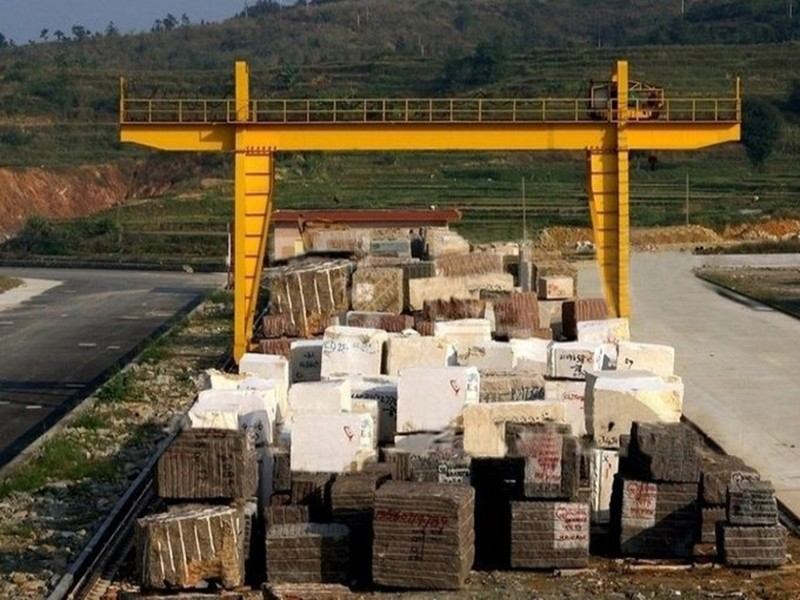

The cement plant double girder gantry crane is ideal for outdoor applications where lifting facilities are provided without the cost of a building or any supporting steelwork. The frame adopts box-type welding mechanism, and the crane travelling mechanism adopts separate drive.

1. Heavy-duty construction: Gantry cranes for concrete are designed to be durable and robust, with heavy-duty materials used in their construction. This allows them to handle the heavy loads and harsh conditions of a construction site.

2. High lifting capacity: Gantry cranes for concrete are capable of lifting and moving large volumes of concrete, often with a lifting capacity of several tons.

3. Flexible movement: The trolley and hoist can move along the bridge in both horizontal and vertical directions, allowing the crane to reach and lift concrete components from different angles and positions.

4. Precise positioning: Gantry cranes for concrete are equipped with controls that allow for precise positioning of the load. This is important when placing concrete components in specific locations within a construction project.

5. Safety features: Safety features are essential in a gantry crane for concrete, including limit switches, overload protection, and emergency stop buttons. These features ensure safe operation and help prevent accidents and injuries.

6. Adaptability: Gantry cranes for concrete can be designed to be adaptable to different types of construction projects. They can be customized to meet specific requirements, such as different lifting capacities or bridge lengths.

Features

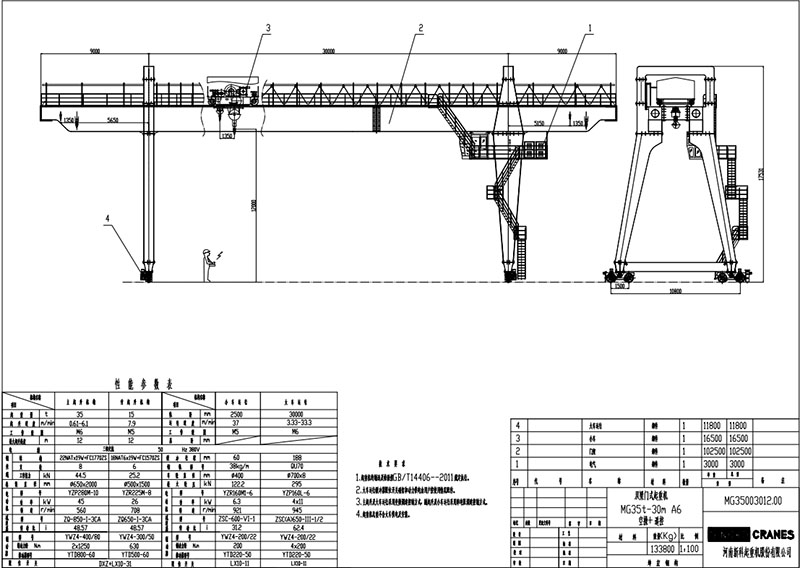

1. Box-shaped double beam welding structure: This type of structure provides strength and stability to the crane while also increasing the working space. It also makes the crane easier to transport, install, and maintain.

2. Opposite rail cable conductive device: This type of device allows the crane to move along the rails while maintaining a continuous electrical connection. This improves the safety and reliability of the crane's electrical system.

3. Standardization, serialization, and generalization of parts and components: By using standardized and serialized parts and components, the crane can be manufactured more efficiently, and maintenance and repairs can be carried out more easily.

4. Cable coil type or sliding line type: These are two options for the electrical system of the crane, allowing users to choose the one that best suits their needs.

5. Driver's cab with a wide field of vision and linkage console: This provides the operator with a clear view of the work area and allows for precise control of the crane's movements.

6. Comfort and convenience features: The crane can be equipped with a range of features, such as a fan, hot air device, air cooler, air conditioner, and walkie-talkie, to improve the operator's comfort and convenience.

Specification

| Double Girder Gantry Crane | |||||||||||||||||||||||||||||||

| Capacity | T | 10T | 20T | 32T | 50T | 80T | 100T | ||||||||||||||||||||||||

| Span | m | 10 | 15 | 20 | 25 | 30 | 10 | 15 | 20 | 25 | 30 | 10 | 15 | 20 | 25 | 30 | 10 | 15 | 20 | 25 | 30 | 10 | 15 | 20 | 25 | 30 | 10 | 15 | 20 | 25 | 30 |

| Cantilever | m | 3 ~ 7 | 3 ~ 7 | 3 ~ 7 | 3 ~ 7 | 3 ~ 7 | 3 ~ 7 | ||||||||||||||||||||||||

| Height of Lifting | m | 6 ~ 15 | 6 ~ 30 | 6 ~ 30 | 9 ~ 30 | 9 ~ 30 | 9 ~ 30 | ||||||||||||||||||||||||

| Lifting Speed | m/min | 5/0.8 | 4/0.66 | 3.3/0.8 | 0~4 | 0~4 | 0~4 | ||||||||||||||||||||||||

| Trolley Speed | 5~20 | 5~20 | 5~20 | 5~20 | 5~20 | 5~20 | |||||||||||||||||||||||||

| Long Travel Speed | 0-20, 0-32, 0-40 | 0-20, 0-32, 0-40 | 0-20, 0-32, 0-40 | 0-20, 0-32, 0-40 | 0-20, 0-32, 0-40 | 0-20, 0-32, 0-40 | |||||||||||||||||||||||||

CASE

Discover Sinoko Crane’s A-Type Cement Plant Double Girder Gantry Crane, designed for heavy-duty cement plant operations. With advanced features and reliable performance, this crane ensures high productivity and safety in demanding environments. Learn more about its specifications and pricing today!

Installation of 10T European-Style Gantry Crane for Pakistani Client by Sinoko Cranes

Struggling with slow manual gates? Sinoko's European gantry crane slashed Pakistan customer's downtime by 64%! Transform your access efficiency – contact us!

Learn More Get a QuotePakistan Scrap Steel Dumping Container Gantry Crane Project Case

The Sinoko crane, leveraging years of experience and outstanding technology, designed a container gantry crane for customers, successfully solving the problem of transporting scrap steel for them.

Learn More Get a QuoteInstallation of 3T Portable Gantry Crane for Thai Manufacturing Facility

The 3 ton portable small gantry crane specially designed by Sinokocranes for Thai customers has significantly reduced the production costs for the customers and enhanced their production efficiency.

Learn More Get a QuoteFAQs

The crane is designed to handle heavy loads with a high lifting capacity, ideal for cement plants.

Yes, the A-Type gantry crane is built for outdoor environments, offering durability in harsh conditions.

The crane offers a customizable span to meet specific plant requirements.

The double girder design ensures greater stability, lifting precision, and faster operation.

Yes, it includes essential safety features like overload protection, emergency stops, and anti-collision systems.

Yes, Sinoko offers customizable options to fit the specific needs and layout of your cement plant.