Overview

Scrap grab bucket cranes are heavy-duty lifting machines designed to lift and transport scrap metal and other materials. They are typically used in industrial and manufacturing settings, and are capable of lifting and transporting large amounts of material quickly and efficiently.

Scrap grab bucket cranes are available in a variety of sizes and configurations, and can be customized to meet the specific needs of the user. They are typically equipped with a grab bucket, which is used to scoop up and transport scrap metal and other materials.

Scrap grab bucket cranes are designed to be durable and reliable, and are capable of lifting and transporting large amounts of material with ease.

Features

• Durable and reliable

• Capable of lifting and transporting large amounts of material

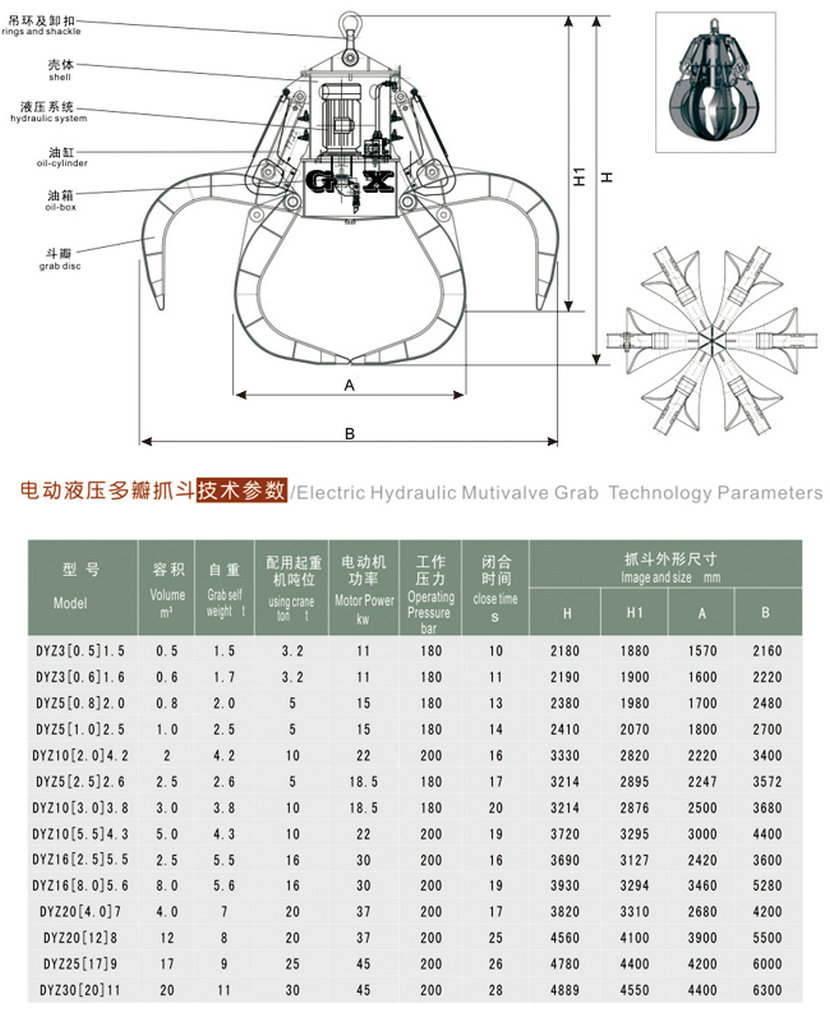

• Equipped with a grab bucket

• Available in a variety of sizes and configurations

• Customizable to meet the specific needs of the user

• Easy to operate and maintain

• Cost-effective solution for lifting and transporting scrap metal and other materials

Specification

Applications of Scrap Grab Bucket Cranes

Scrap grab bucket cranes are commonly used in a variety of industries and applications. They are often used in the construction industry for lifting and transporting large amounts of material, such as scrap metal, concrete, and other debris. Additionally, they are used in the mining industry for lifting and transporting ore and other materials. They are also used in the manufacturing industry for lifting and transporting heavy materials, such as steel and other metals. Finally, scrap grab bucket cranes are also used in the recycling industry for lifting and transporting scrap metal and other materials.

Safety Considerations for Scrap Grab Bucket Cranes

Safety is of the utmost importance when operating a scrap grab bucket crane. It is important to ensure that the crane is properly maintained and inspected regularly to ensure that it is in good working condition. Additionally, it is important to ensure that the operator is properly trained and certified to operate the crane. It is also important to ensure that the crane is operated in accordance with the manufacturer’s instructions and safety guidelines

CASE

See how Sinoko Crane solutions are applied across diverse industries, from scrap yards and recycling centers to steel plants and ports. Browse our project case studies to discover how we deliver tailored, high-performance lifting systems for heavy-duty material handling challenges.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

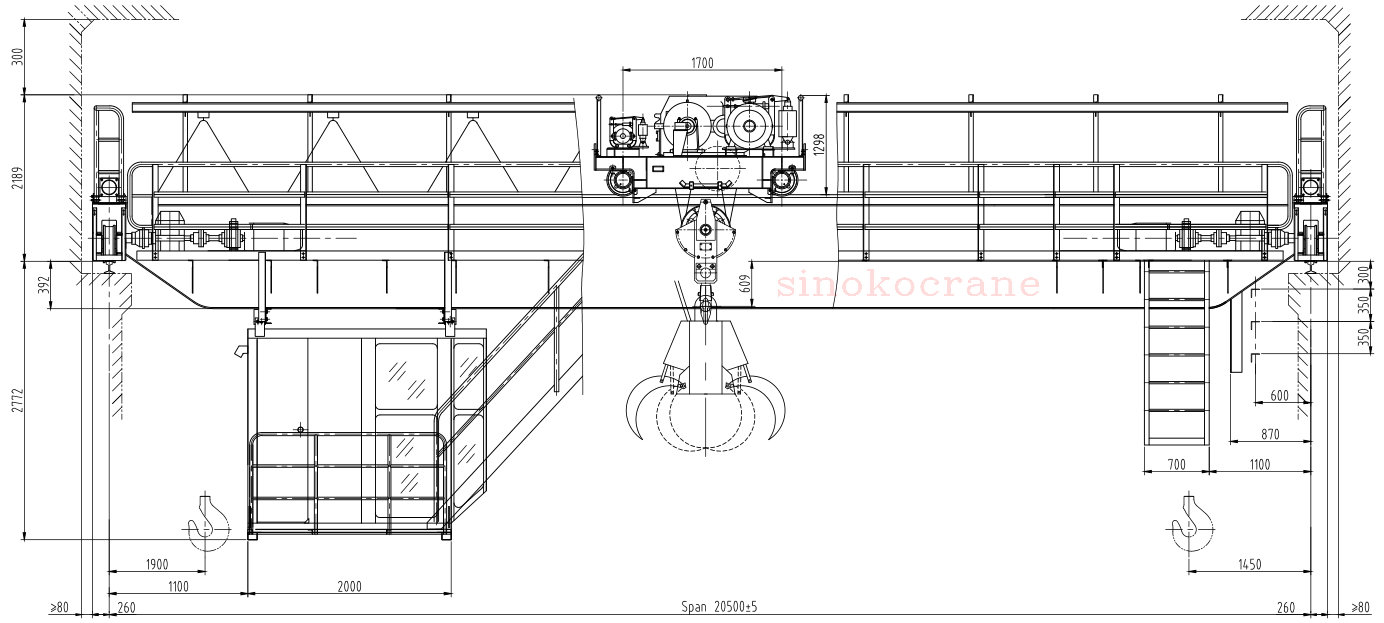

A Steel Scraps Grab Bucket Crane is a robust overhead lifting solution featuring a box bridge frame, grab trolley, long-travel mechanisms, driver cabin, and electrical control system. It's purpose-built for swift and efficient loading and transport of scrap metal and bulk materials, reducing labor costs and boosting productivity.

This crane is highly adaptable—available in multiple sizes and configurations—with options to tailor the grab bucket, bridge span, control systems, and other features to meet specific operational needs.

Commonly deployed across sectors like construction, mining, manufacturing, and recycling, the crane excels at handling scrap metal, concrete debris, mining ore, and similar materials in fast-paced industrial environments.

Users enjoy significant gains in efficiency and cost-effectiveness: the crane enables large-scale bulk handling with minimal manpower, using durable components that support long-term, reliable performance.

Designed with rugged durability and straightforward functionality in mind, this crane features a sturdy box bridge structure, smooth electrical controls, and intuitive cabin operation—making it reliable and user-friendly, even in demanding industrial conditions.

Ensuring safety and efficiency involves conducting regular maintenance, adhering to operating guidelines from the manufacturer, and employing trained, certified operators to maintain optimal performance and safety standards.