Overview

Sinokocranes’ jib crane also called vertical cantilever crane, which has the characteristics of high efficiency, energy saving, ease of operation, small occupation area, easy operation and maintenance. Especially for short distance, use frequent, dense crane operation, it can be installed in any situation you can think of, is a practical light position hoisting equipment.

The 5 Ton Jib Crane is a versatile and efficient lifting solution designed to handle loads up to 5 tons. With its compact design and flexible rotation, this jib crane provides easy and precise material handling in various industrial settings. It is an ideal choice for workshops, warehouses, assembly lines, and other areas where space is limited, yet heavy lifting is required.

Sinokocranes have a wide range of options available, including heavy-duty and lightweight jib cranes. such as portable jib crane, floor-mounted jib crane, small jib crane, wall-mounted jib crane, rotating jib, and customized designs in meeting different customer needs.

Features

(1) Rich product layout

It is rich in variety and full of specifications. You only need to tell us the rated load, arm length, lift height, rotation angle and corresponding functional requirements. We provide the most reasonable solution for you.

(2) Reasonable structural design

Simple and not easy, this is our design concept that allows you to have a more relaxed and enjoyable operation experience in terms of strength, rigidity, and safety.

(3) Economize the cost of factory

The main parts’ production has standard process, stable quality, reliable performance, good versatility, and high cost performance, avoid later maintenance accessories and high cost.

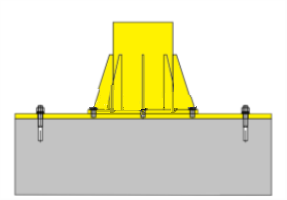

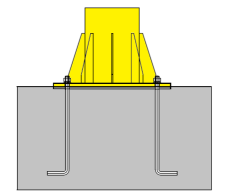

How the Jib crane columns connect with the ground?

|

|

Expansion bolts connecting type | Cement pouring type |

As the above pictures showing, there are two connecting modes for jib cranes connection.

First type is using expansion bolts connect with thee cement ground, this type is much easyer and fast for installation. 5ton or more capacity jib cranes are suitable for this type connection.

Second type is pouring cement into the ground pit, which is suitable for small capacity, like 500kg,1000kgs.

Specification

| Model | Capacity (kg) | Arm Length (mm) | Lifting height (mm) | Ground pit size (mm) |

| SJB-0.5 | 500 | 3000-6000 | 215-315 | 1000*1000*800 1200*1200*900 |

| SJB-1 | 1000 | 3000-6000 | 265-415 | 1400*1400*1100 1800*1800*1200 |

| SJB-2 | 2000 | 3000-6000 | 315-515 | 1600*1600*1200 2000*2000*1400 |

| SJB-3 | 3000 | 3000-6000 | 315-515 | 1600*1600*1200 2000*2000*1400 |

| SJB-5 | 5000 | 3000-6000 | 415-515 | 1600*1600*1200 2000*2000*1400 |

Enhance your material handling capabilities with the versatile 5 Ton Jib Crane. Experience efficient and precise lifting, compact design, and reliable performance. Contact us today to learn more about this jib crane and how it can optimize your operations!

CASE

Explore case studies showcasing how Sinoko Crane solutions are applied in real industrial environments. From custom jib crane setups to large-scale lifting systems, discover how we help clients worldwide improve efficiency, safety, and operational precision.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuotePakistan Scrap Steel Dumping Container Gantry Crane Project Case

The Sinoko crane, leveraging years of experience and outstanding technology, designed a container gantry crane for customers, successfully solving the problem of transporting scrap steel for them.

Learn More Get a QuoteFAQs

This crane offers high efficiency, energy savings, compact space usage, and ease of operation and maintenance—making it especially practical for lifting tasks that are frequent, localized, and in dense operating conditions. It’s a versatile tool for light positional hoisting needs.

Sinoko provides a comprehensive product layout: simply specify your rated load, arm length, lifting height, rotation angle, and any special functions, and they tailor the most efficient design solution for you.

There are two main mounting options: expansion bolts for quicker installation—ideal for capacities of 5 ton and above—and a ground‑pit plus cement‑pouring method suited for lower capacities.

Its compact footprint, flexible rotation, and high lifting capacity make it a great fit for workshops, warehouses, assembly lines, and other industrial zones where space constraints and workflow density demand efficient, safe lifting.

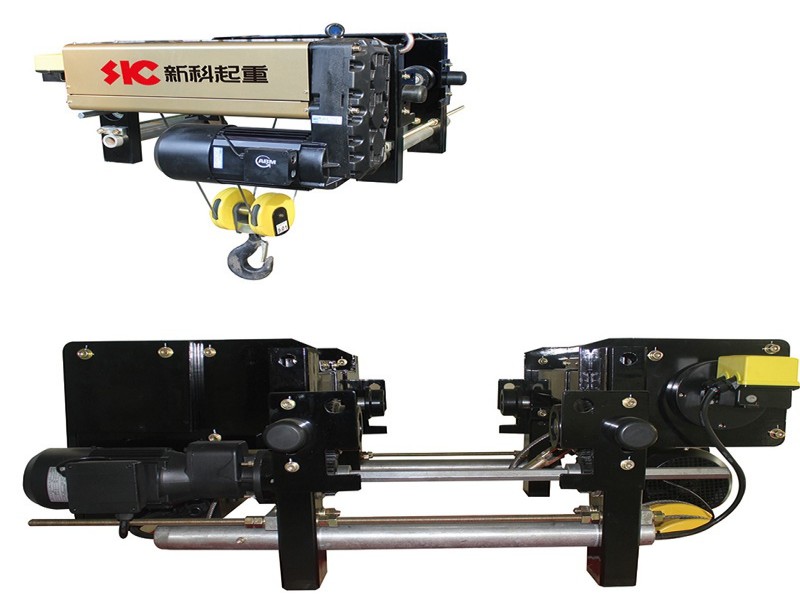

European‑style cranes typically feature lighter, lower‑height structures, reduced dead weight, smaller wheel loads, and enhanced energy efficiency—often delivering over 30 % energy savings, quieter operation, and smoother control, enabling cost reductions in facility construction and long‑term operations.

With modular design for easy customization and maintenance, efficient operation patterns for dense lifting tasks, and advanced safety features aligned with European standards (like limit switches and reliable hoist systems), this crane delivers both operational adaptability and long‑term performance reliability.