Overview:

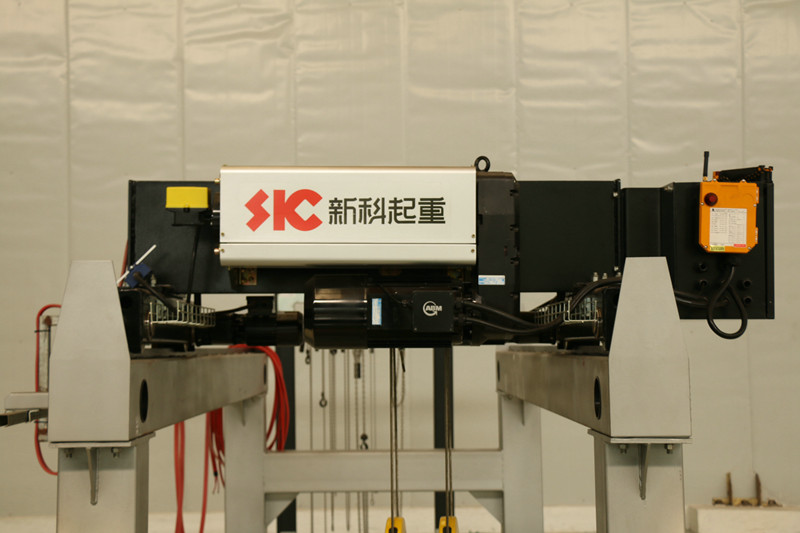

FEM Standard Monorail Gantry Crane is used together with electric hoist. Its proper lifting weight is 3 to 20 tons. Proper span is 12 to 30 meters, its proper working temperature is -20℃ to 40℃. FEM Standard Monorail Gantry Crane is a regular crane, widely used at open ground and warehouses to load, unload or grab materials. It has 2 controlling methods, namely, ground controlling and room controlling.

Applications Of Single Girder Gantry Cranes

Single girder gantry cranes are conventional cranes designed for general material handling, and are often used in open fields, warehouses, ports, granite industries, cement pipeline industries, open storage yards, container yards, shipyards and other places. However, it is forbidden to handle molten metal, flammable and explosive materials.

As one of the leading gantry crane suppliers and manufacturers, Sinoko designs and manufactures gantry cranes suitable for all industrial applications, providing solutions for both indoor and outdoor applications. Contact us to purchase the right gantry crane for your application!

Features

● Advanced processing equipment and manufacturing processes;

● Maintenance-free design

● Use CAD for structural design and calculations;

● Safe, reliable, durable;

● Small size, light weight, low noise, high efficiency;

● Compact structure, easy installation and maintenance, durable;

● Low building clearance height and low wheel pressure;

● The structure is novel and beautiful in appearance;

● Good craftsmanship, flexible and stable operation, safe and reliable.

Specification

| Loading Capacity | 0.5~50t |

| Lifting Height | 3~30m or customized |

| Lifting Speed | Single speed: 3~8 m/min or customized |

| Variable speed: 1/10 m/min or customized | |

| Span | 3~35m |

| Left Cantilever | 0~4m or as require |

| Right Cantilever | 0~4m or as require |

| Lifting Mechanism | Wire rope hoist or electric chain hoist |

| Work Duty | M3~M5 |

| Power Supply | AC-3Phase-220/230/380/400/415/440V-50/60Hz |

| Control Method | Ground handle control(Push button), wireless remote control, cabinet control |

| Application Area | Factory,workshop,warehouse,power station,logistic,etc. |

| Color | Red, yellow, or customized |

| Working Temperature | -20~40℃ |

| Protection Class | IP54; IP55; IP65 |

CASE

Discover how our Outdoor RMG Type Rail Mounted Cantilever Travelling Gantry Crane can streamline your operations. Trusted by ports and large-scale industrial sites, this crane offers unmatched lifting capacity, durability, and efficiency for heavy-duty tasks. Learn more about real-world applications!

40.5T Rail-Mounted Gantry Crane Installation for Port Logistics Efficiency

The RMG gantry crane designed and manufactured by Sinokocrane has effectively solved the problems for the customers and reduced their operational costs.

Learn More Get a Quote5T Portable Gantry Crane Deployment for Australian Equipment Rental

The portable gantry cranes provided by Sinoko Cranes for the leasing company of Australian customers have significantly increased the number of rentals for the customers and enhanced the revenue of their companies.

Learn More Get a QuoteInstallation of 10T European-Style Gantry Crane for Pakistani Client by Sinoko Cranes

Struggling with slow manual gates? Sinoko's European gantry crane slashed Pakistan customer's downtime by 64%! Transform your access efficiency – contact us!

Learn More Get a QuoteFAQs

An Outdoor RMG (Rail Mounted Gantry) Crane is a heavy-duty crane designed for outdoor use, typically used in ports and large warehouses. It is mounted on rails and can move along them to lift and transport containers or heavy loads efficiently.

This crane features a cantilever design, providing excellent stability and lifting capacity. It is designed for long-lasting performance with high safety standards, including advanced control systems and durable materials for outdoor environments.

RMG cranes are primarily used in container yards, ports, and large industrial facilities. They are ideal for transporting containers in and out of storage areas and are commonly found in maritime logistics, railways, and warehouses.

The lifting capacity varies depending on the model, but generally, these cranes can lift loads from 10 to 100 tons or more, making them suitable for large-scale material handling.

Yes, this crane is designed specifically for outdoor use. Its robust construction ensures it can withstand harsh weather conditions such as rain, wind, and extreme temperatures, making it perfect for ports, shipping yards, and similar outdoor applications.

Regular maintenance includes inspecting the rails, crane components, electrical systems, and safety devices. Periodic lubrication of moving parts and checking for wear and tear will ensure smooth operation and extend the crane’s lifespan.