The FEM Crane series mainly includes European overhead cranes, European gantry cranes, jib European cranes and other industrial cranes and related European hoists and parts, etc.

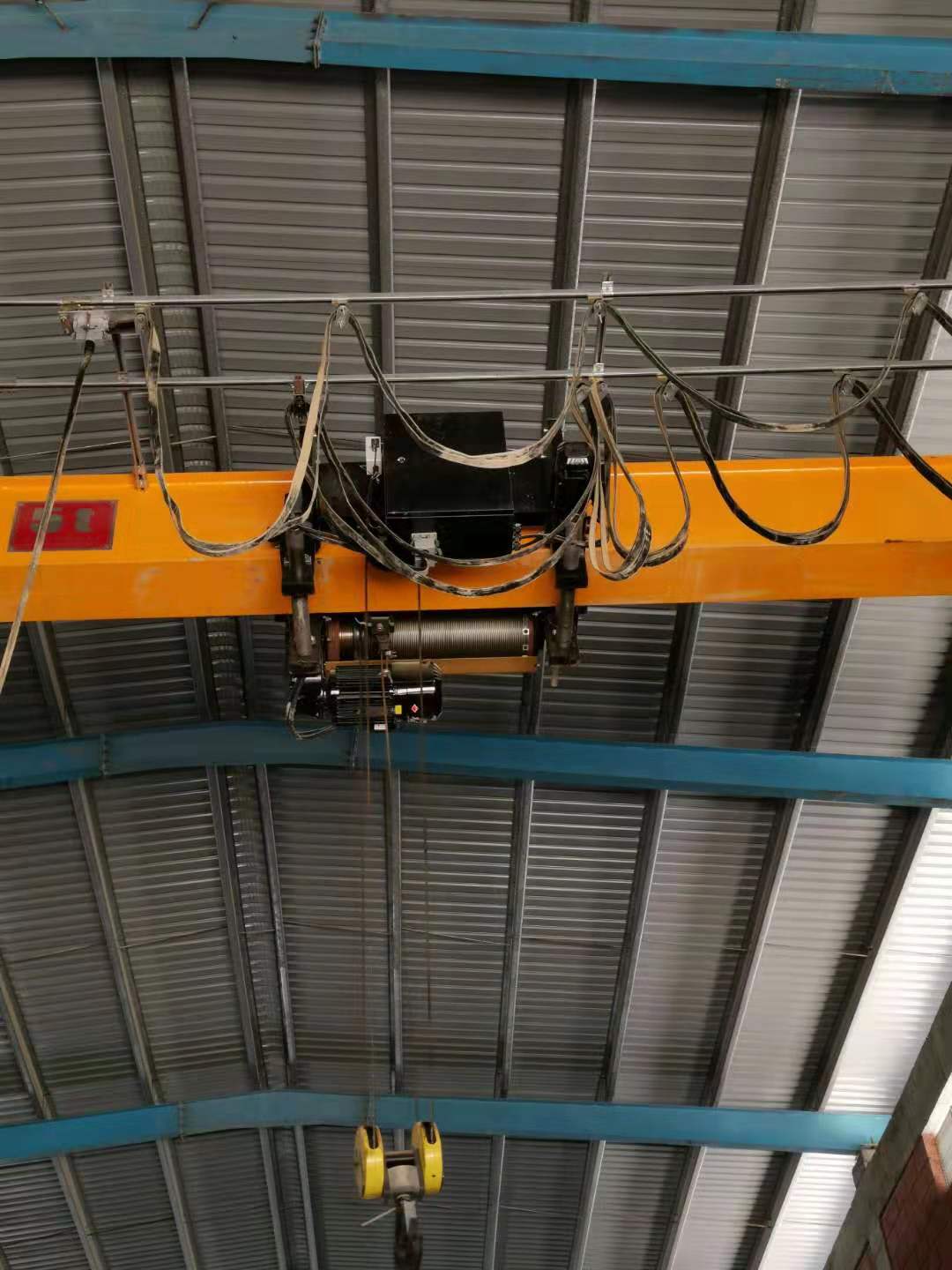

European Crane is mainly composed of main bridge, electric hoist, crane traveling mechanism, electrical control system and other components.

Safety & Mechanical Features | |

1 | European crane is compact lifting machinery designed and manufacturing in the strict according with FEM,DIN and ICE standard, compared with general overhead crane (bridge crane), weight is reduced by about 15-30% of common crane, max wheel pressure is reduced by about 10-30%. Have less requirement to the workshop structure, reduce production cost. |

2 | The frame of crane beam is square box frame, it is made by Q235 or Q345 steel plate, it has smaller body to get more lifting space. |

3 | Motoradopts Insulation grade F, protective grade IP54, it shall also have over heated and alarming function, the motor cover adopts aluminum alloy to drawing the molding, with better heat dissipation. |

4 | Germany reducer, Harden face gear, improve the bearing ability, better sealing of the shell, ensure there no grease penetration. |

5 | Bridge crane wheel assembly are technically advanced and successfully used in different industries like steel plant, rolling mill, cement plant, fertilizer plant, paper mill, chemical industries, etc. Wheel material: ZG430-640 cast steel, 60#, 65$ 65Mn, 42CrMo, 45# or according to your demand. |

6 | Main electric elements adopts the international brands include Schneider, Siemens, ABB. The protective grade of electric control box shall not less than IP55 |

7 | This overhead crane(bridge crane) has several safe protection functions, such as up/down limit switch, overload protection, low-voltage protection and long traveling limit switch, and the cross and long traveling motors have soft start function, the crane is very easy to use. |

8 | This overhead crane(bridge crane) is widely used in plants, warehouses, material stocks to lift goods. It is prohibited to use the equipment in the combustible, explosive to corrosives environment. |

9 | The all motions of this overhead crane are double speeds, the lifting motor is double speed type, the cross traveling motor and long traveling motor are controlled by frequency inverter. |

If you need custom designed FEM Crane, please leave us a message or send an email to info@sinokocrane.com, Get your European Crane at good price now.

CASE

Based on their intended use, overhead cranes can be classified into general-purpose cranes, steel mill cranes, and explosion-proof cranes. Each type is designed with specific working environments and load requirements in mind, ensuring safety and efficiency.

3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteFAQs

An FEM Standard Single Beam Overhead Crane is a type of electric crane designed according to European FEM standards. It is ideal for lifting heavy loads in industrial environments, offering efficient, reliable, and safe operations.

This crane is commonly used in industries such as manufacturing, warehousing, construction, and material handling, where heavy lifting and high-frequency operations are required.

The load capacity varies depending on the model but typically ranges from 1 to 20 tons, depending on the specific design and customer requirements.

FEM standards ensure that the crane is designed with high safety margins, reducing risks during operation. These include features such as overload protection, smooth operation, and durable components for long-term performance.

Regular maintenance includes checking the hoist, crane tracks, and electrical systems. Lubricating moving parts, inspecting safety devices, and conducting periodic load tests are crucial for ensuring safe and efficient operation.

Yes, we provide professional installation services and operator training to ensure your crane operates efficiently and safely from day one.