Double Girder Top Running Overhead Crane Components

Same as Single Girder Bridge Crane, double girder overhead crane mainly include three major operating mechanism: Lifting mechanism, long traveling mechanism, Cross traveling mechanism. Among them, the Lifting operation mechanism is mainly composed of an electric hoist, a wire rope, a pulley, a hook or a spreader.

The metal structure of the Double Girder Top Running Overhead Crane is mainly composed of two parts, the main beam and the end beam. The main beam structure of the Double Girder Top Running Overhead Crane is mainly composed of a cover plate, a web and an I-beam. The box body has a vertical and horizontal length and length. Reinforced ribs. Its safety and reliability directly affect the crane's operating quality and working ability.

Features

Double Girder Top Running Overhead Crane Lifting Mechanism

Lifting mechanism and hoist operation mechanism adopts low headroom speed (SWF) wire rope hoist.

Double Girder Top Running Overhead Crane Cross Traveling Mechanism

Double Girder Top Running Overhead Crane electric hoist operating mechanism for the electric car type. The reduction gear is 40Cr forged, and after quenched and tempered, it is installed in a closed gear box, all of which are supported by rolling bearings. The wall plate is made of steel plate, which ensures flexible operation, convenient use and long service life.

The trolley running mechanism is equipped with an inverter, stepless speed regulation, stable operation, accurate positioning and comfortable operation.

Double Girder Top Running Overhead Crane Long Traveling Mechanism

Double Girder Top Running Overhead crane's long traveling structure consists of three in one device & wheel set. The wheel is a 45# forging. The hardness after heat treatment is HB ≥ 330-390 on the tread and HB ≥ 260 at the depth of 20mm. Shafts and gears are made of modified 45# or 40Cr. The cart drive is a new type of LDA drive device. The device has the advantages of simple structure, small size, large starting torque, frequent starting, stable operation speed, low noise, safe and reliable use, convenient installation and maintenance, and nice appearance.

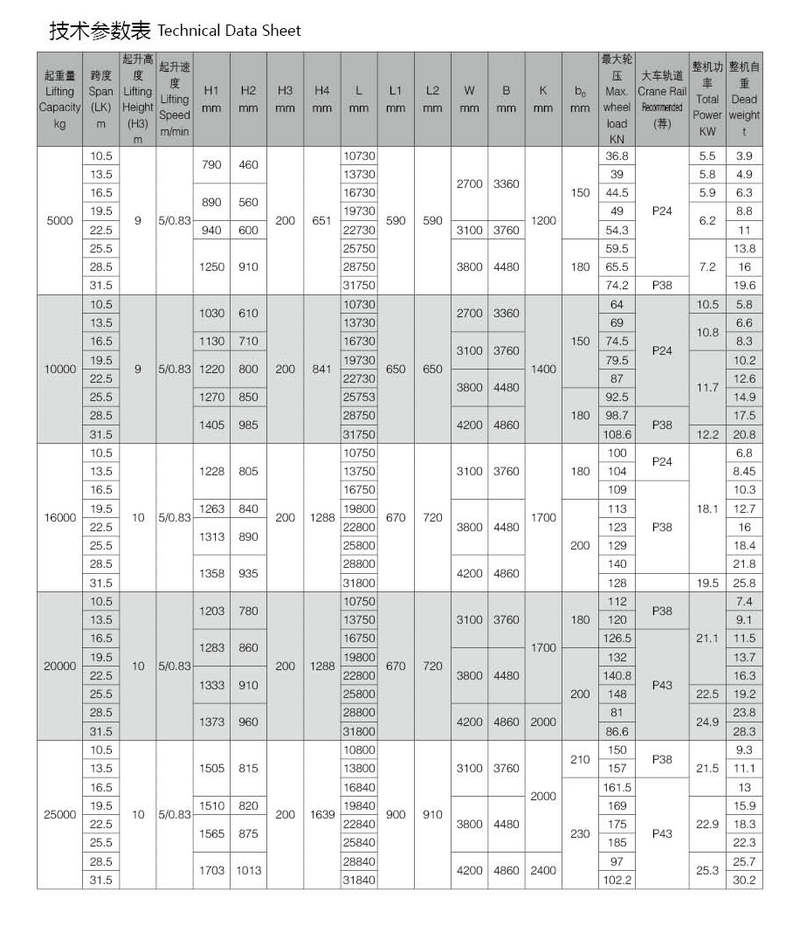

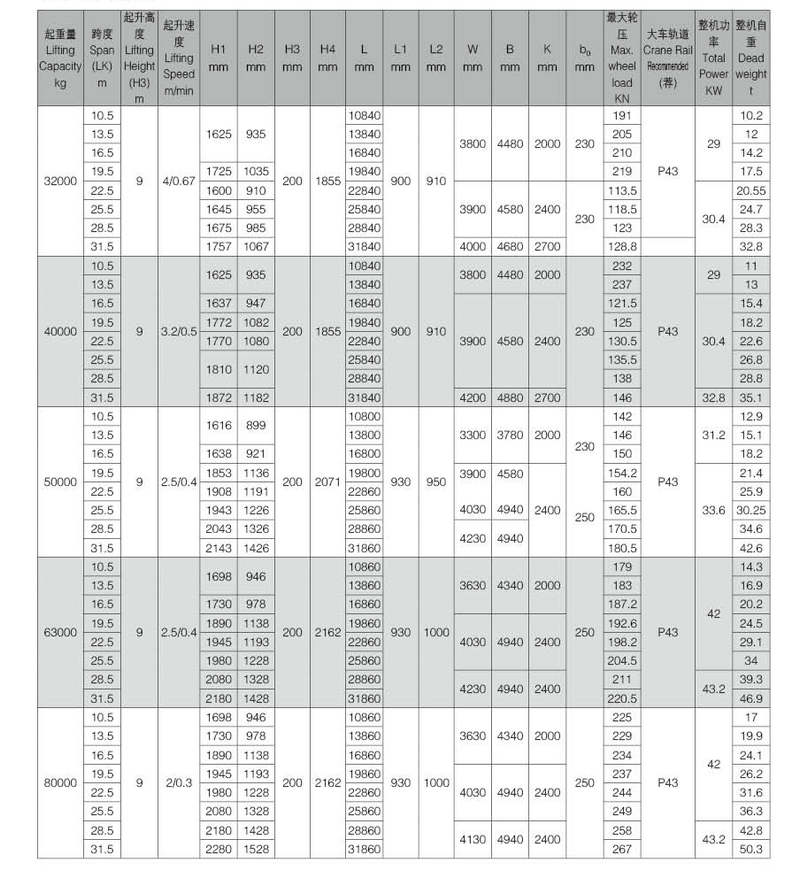

Specification

CASE

Interested in how our double girder cranes perform in real operations? Browse our crane project cases to see Sinoko solutions in action across global industries.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

A double‑girder top‑running crane features two parallel bridge girders with the hoist and trolley riding on top. It’s ideal for heavy-duty lifting, long spans, and maximized hook height—perfect for steel mills, foundries, and large fabrication environments.

Because the hoist runs on top of the beams rather than below, double‑girder cranes typically offer an additional 18–36 inches of hook lift over single‑girder models.

This design provides the greatest hook height, accommodates higher load capacities, enables longer spans, and makes it possible to add walkways, cabs, or maintenance platforms—Ideal for demanding industrial settings.

They're well-suited to environments requiring frequent heavy lifting—such as steel plants, railyards, shipyards, paper mills, and heavy machinery manufacturing—especially when headroom and strength are critical.

These cranes are highly scalable—from moderate loads of 5–20 t to ultra-heavy loads exceeding 500 t—and span ranges can extend from around 10 m to over 35 m, making them suitable for extremely varied industrial demands.

They require more material and structural support—meaning the building must withstand greater weights and stresses. Planning for runway support and possibly extra columns is essential.