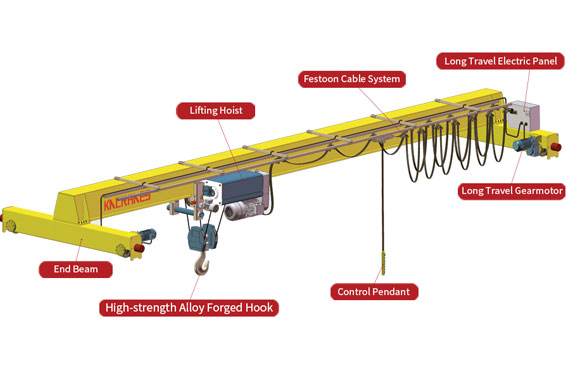

As a versatile lifting solution, the 5 ton overhead pendant crane is designed to efficiently handle loads weighing up to 5 tons in various industrial applications. It is equipped with a pendant control system that allows for precise and easy operation. The overhead pendant crane is commonly used in workshops, warehouses, assembly lines, and other work environments where medium-weight lifting is required.

Features

Light self weight, low noise and few faults, generally used in normal working condition.

Designed base on DIN standard from German.

Save the power, lower wheel load, so it can reduce the cost of support beam.

Brand motor, the insulation grade is F, and protective grade is IP54, it shall also have over heated and alarming function, the motor cover adopts aluminum alloy to drawing the molding, with better heat dissipation.

The wheel forged by 65 Mn alloy steel, with the performance of abrasive resistance, ant fatigue and long service life.

Safety Features

♦ Lifting and travelling limit switches

♦ Emergency Stop

♦ Loss voltage protection

♦ Grounded protection

♦ Overload protection

♦ Short circuit protection

♦ Overheating protection

♦ Overspeed protection

♦ Overcurrent protection

♦ Faulted phase protection

Specification

| Capacity (t) | 5 |

| Span (m) | 10.5-31.5 |

| Lifting Height (m) | 9 |

| Lifting Speed (m/min) | 5/0.83 |

| Max. Wheel Load (KN) | 36.8-74.2 |

| Total Power (KW) | 5.5-7.2 |

| Total Weight (T) | 3.9-19.6 |

Contact us today to learn more about our 5-ton overhead pendant crane and how it can improve your material handling processes. Our team of experts is ready to assist you in finding the right lifting solution for your specific requirements.

CASE

Explore our project case studies to discover how Sinoko’s overhead cranes are helping businesses across industries improve lifting efficiency, safety, and reliability.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

The 5-ton Overhead Pendant Crane is a European standard-designed lifting solution optimized for precision and stability. Equipped with a pendant control system, it’s widely used in workshops, warehouses, and assembly lines for medium-weight lifting tasks.

With a light self-weight, low noise operation, and minimal faults, this crane is ideal for normal working conditions. Its efficient design (DIN standard) also reduces wheel load, helping to lower support beam requirements and associated installation costs.

It uses brand-name motors rated with F insulation and IP54 protection, including overheating alarms and aluminum alloy housings for better heat dissipation. The forged 65 Mn alloy steel wheels provide resistance to abrasion, fatigue, and offer extended service life.

The crane includes a comprehensive safety suite: lifting and traveling limit switches, emergency stop, undervoltage protection, grounding protection, overload and overcurrent safeguards, short-circuit protection, overheating protection, overspeed protection, and fault-phase detection.

Standard parameters include spans from 10.5 to 31.5 meters, a typical lifting height of around 9 meters, lifting speeds of approximately 5 m/min (or 0.83 m/min in precision mode), wheel loads between 36.8–74.2 kN, and total power requirements ranging from 5.5 to 7.2 kW.

Sinoko’s design leverages site conditions to tailor fabrication steps for each client's needs. Through optimized engineering that emphasizes strength, stiffness, and stability, this process ensures that the crane is customizable and aligned with project-specific installation requirements.