Overview:

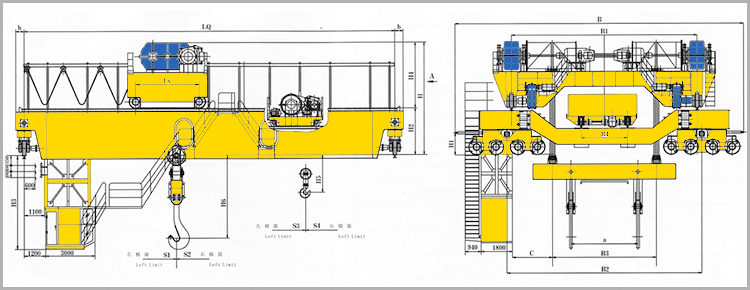

The charging crane are usually designed as double independent trolley type, or single trolley type as the lifting mechanism. According with the structure of feed spout, for 3 ear bearing type feed spout, the charging crane should design the hook which close to the feed spout as double lifting point hook. The hook which is far away the feed spout should be designed as single hook type.

For 4 ears type feed spout, the charging crane should be designed the main hook and auxiliary hook as double lifting point hooks. Normally double trolley type is very popular for long sqaure steel scrap basket lifting:

Features

The charging crane have included several components such as electrical control equipment, trolley system, crane traveling mechanism, crane girder, hooks etc. Since the scrap did not separate very balance in the feed spout, the charging crane design should consider the unbalance loading. The charging crane are lifting the steel scrap basket and charging them into converter, it have speed requirements for main hook and auxiliary hook. The speed should be synchronized variable speed.

Specification

| Rated load/ton | 5 | 10 | 16 | 20 | 25 |

| Span/m | 10-40 | ||||

| Lifting height/m | 22 | ||||

| Working class | A6/3M | ||||

| Lifting speed/m/min | 40.8 | 40.26 | 41.8 | 48.5 | 38.8 |

| Open-close speed/m/min | 40.8 | 40.26 | 41.8 | 48.5 | 38.8 |

| Trolley running speed/m/min | 44.5 | 45.6 | 43.2 | 43.2 | 43.2 |

| Crane running speed/m/min | 92 | 86.5 | 87 | 87 | 87 |

| Dead weight/t | 17.5~38.5 | 25.1~46.6 | 43~63 | 50.6~70.7 | 54.2~75.8 |

| Number of wheel | 4 | 4 | 4 | 4 | 4 |

| Max.wheel pressure/KN | 75~17.4 | 117~186 | 202~258 | 235~302 | 255~320 |

| Steel track recommended | P43 | P43 | P43 | QU70 | QU70 |

| Power supply | 3AC 220~480V 50/60Hz | ||||

CASE

Sinoko Crane's EAF (Electric Arc Furnace) Converter Charging Crane is built for heavy-duty industrial operations. Designed to handle molten metal and material charging in steel mills, it ensures safety, efficiency, and precise operation in extreme conditions.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

An EAF Converter Charging Crane is specifically designed for charging materials into electric arc furnaces, commonly used in steel production for handling molten metal and other heavy materials.

EAF charging cranes are primarily used in steel mills, foundries, and metal production facilities, where they handle raw materials and molten metals safely and efficiently.

The lifting capacity varies depending on the model and specifications. Please refer to the product page for specific load-bearing details.

Sinoko's EAF cranes are equipped with advanced safety features, including overload protection, precise control systems, and durable components for safe operation in high-temperature environments.

Yes, Sinoko offers customization options, allowing the crane to be adapted for different furnace sizes and operational needs.

Routine maintenance includes checking the crane’s electrical and mechanical components, lubricating moving parts, and ensuring that safety systems are functioning properly to maintain efficiency and longevity.