Overview

Advantage of scrap shed iron scrap handling grab bucket

1.Handling steel scrap , irregular block.

2.Powered by a electric motor of high performance

3.Compact structure with built-in hydraulic system

Features

Working Principle of Scrap Handling Grabs

1. Grab frame: Q345 steel

2. Grab peel: The peel is made of Q345 and the edge is made of high wear-resistance steel for stable performance and long service life

3. Grab mechanism: Motor, hydraulic pump, valve block, pipes and hydraulic oil tank

4. Protection grade: Up to IP 65, different according to working requirements and environment

5. Coating thickness: up to 180 μm

Specification

| Volume (m3) | Motor 40%ED (kw) | Crane SWL (t) | Grab Weight (kg) |

| 0.5 | 7.3 | 2.5 | 945 |

| 1 | 7.3 | 3 | 1490 |

| 2 | 10 | 5 | 1540 |

| 2.5 | 10 | 6.3 | 2825 |

| 3 | 14.5 | 10 | 3040 |

CASE

Explore more crane project cases to discover how Sinoko solutions are used across different industries and materials handling environments.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

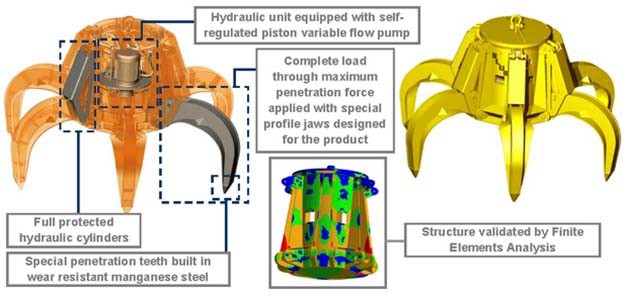

Designed for harsh environments and irregularly shaped scrap, this grab bucket features a built‑in hydraulic system powered by a high‑performance motor and an American hydraulic unit to ensure efficient and reliable operation.

It supports a wide voltage range from 220 V to 440 V and uses a premium German brand motor, guaranteeing compatibility and dependable power delivery for various crane setups.

Volume options range from 0.5 m³ to 3 m³, with matching crane safe working loads (SWL) from 2.5 tons up to 10 tons, and grab weights spanning 945 kg to 3040 kg.

The grab is built with Q345 steel and features heavy-duty wear-resistant edges to withstand harsh materials. Additionally, protective coatings up to 180 µm thick and an IP65 rating help it endure tough operating environments.

Hydraulic cylinders open and close the grab, powered by an electric motor with an integrated hydraulic pump. Commands and electrical power are supplied via a cable from the crane, with an optional cable guide on the crane jib for convenient handling.

Yes—Sinoko offers a fast turnaround with a 30‑day shipment time for urgent orders, ensuring rapid deployment when needed.