Overview

Sinokocranes Follow the most advanced technology of electric hoist design. Make innovation for hoist inteligent functions, high safey by monitoring system.

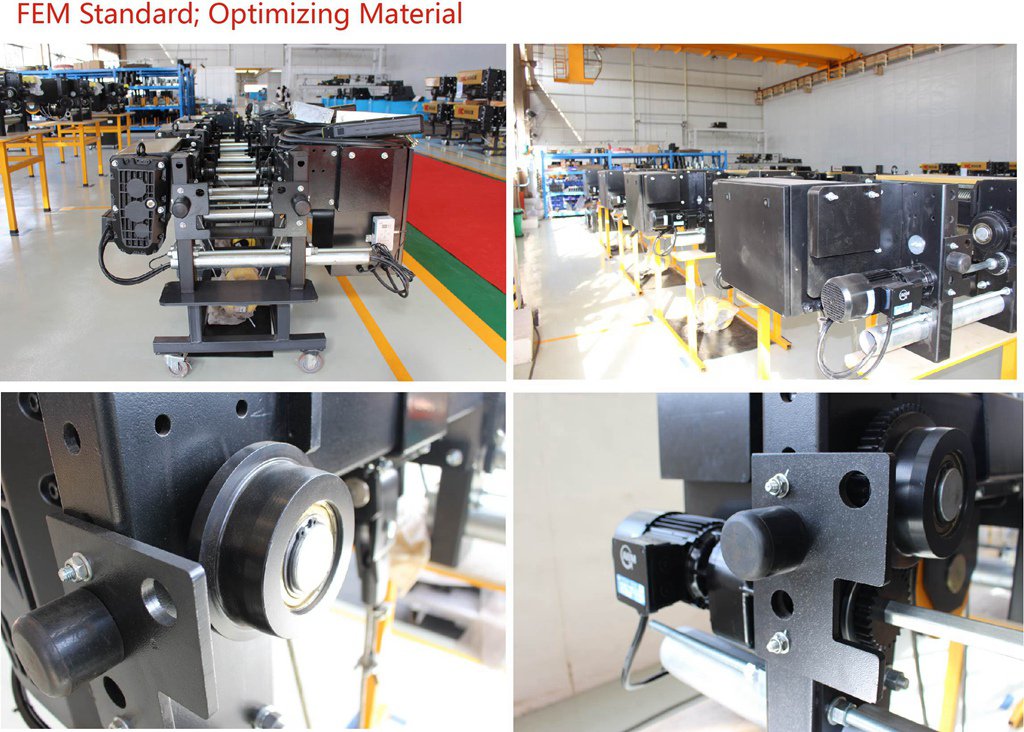

We have supplied the high quality electric hoist of FEM Standard for many advanced users.

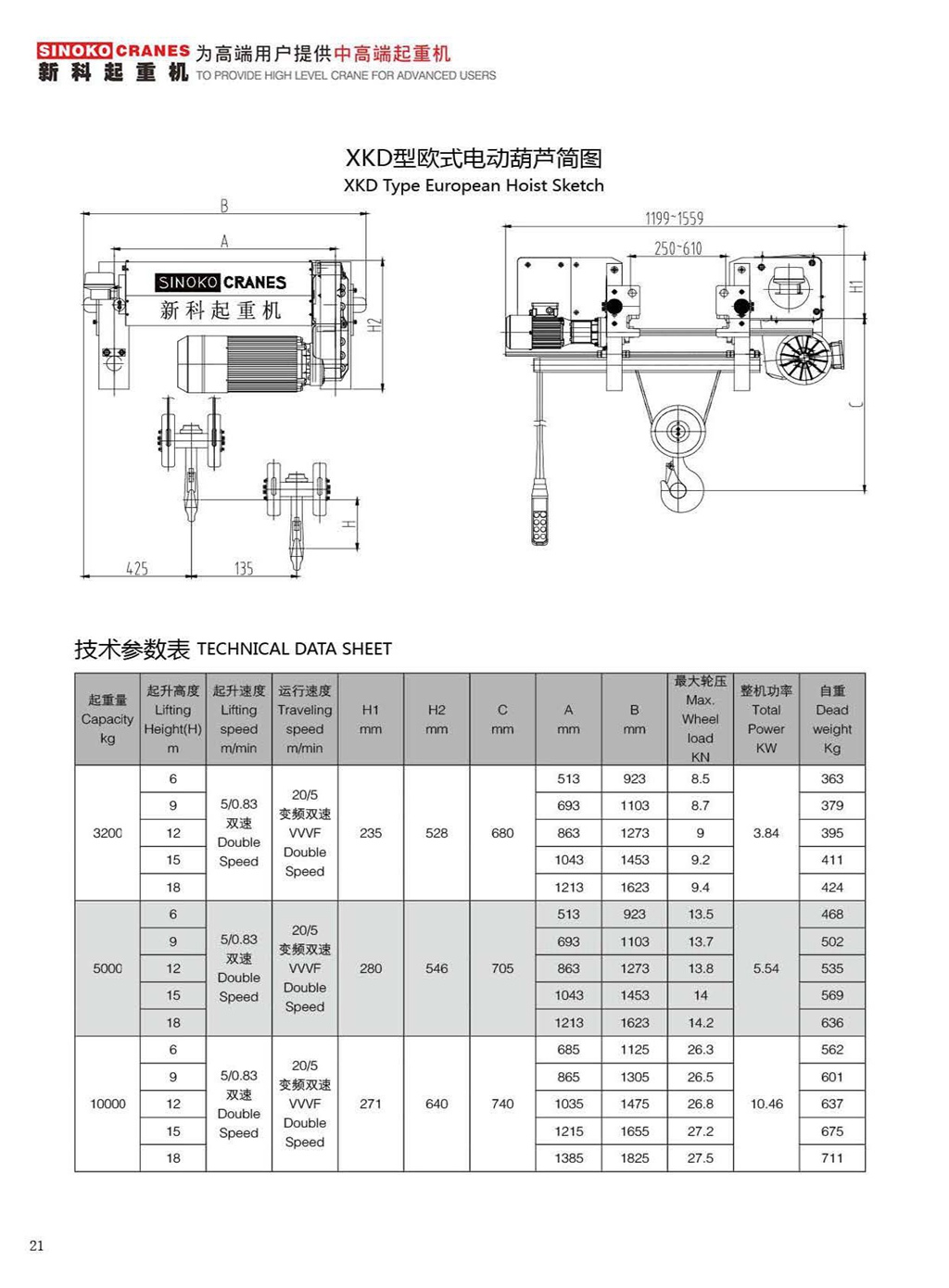

The frontier techniques and component performance of the European electric hoist ensure the product size and equipment height. The compact structure is ensured under the premise of ensuring performance. In the same workshop and work area, the European electric hoist can cover a larger operation scale and increase the internal area of the factory. Application rate, reduce dead zone. If the design is based on the parameters of the finished product during the design stage of the plant, the request for the height of the plant and the bearing capacity of the lifting equipment can be greatly reduced, so that the customer can reduce investment in the plant by more than 10% and promote investment efficiency.

Features

1. Working level: FEM2M; FEM3M (ISOM5; ISOM6)

2. Three-stage transmission, involute helical gears, oil bath cast aluminum gearbox system. The precision gear set works in leak-proof cast aluminum gearboxes. The housing of the gear box is designed to be easily cooled by air and is easy to repair when a fault occurs. Provides low headroom design specifications while ensuring maximum lift height. Save your costs and improve efficiency. The hoist motor is a two-speed adjustment type, which can increase the vulgar ratio to 6:1. It can meet the requirements of positioning, high-speed operation, and quick takeoff and landing.

3. The rope groove adopts deep groove design and standard high-strength wire rope guiding mechanism to ensure that the rope is tighter and more regular.

Ensure lifting safety while extending the life of the wire rope.

4. High-strength DC disc brakes can achieve up to 2 times the nominal torque, enabling fast, active braking and holding

5. Traction wheels made of alloy steel can be used on wide rails or even on curved rails. Drive wheels on both sides of the main engine provide more active drive guidance.

6. All electrical control components use a safe IP54 protection level and you can easily access the parts you need to see when needed.

7. High-strength metal structure is safe and reliable, to ensure the stable operation of the host.

8. The trolley mechanism can be easily adjusted to adapt to different track widths.

9. In the upgrade of high-end range, it is possible to arbitrarily set the upper limit position to meet the most extensive use requirements.

Specification

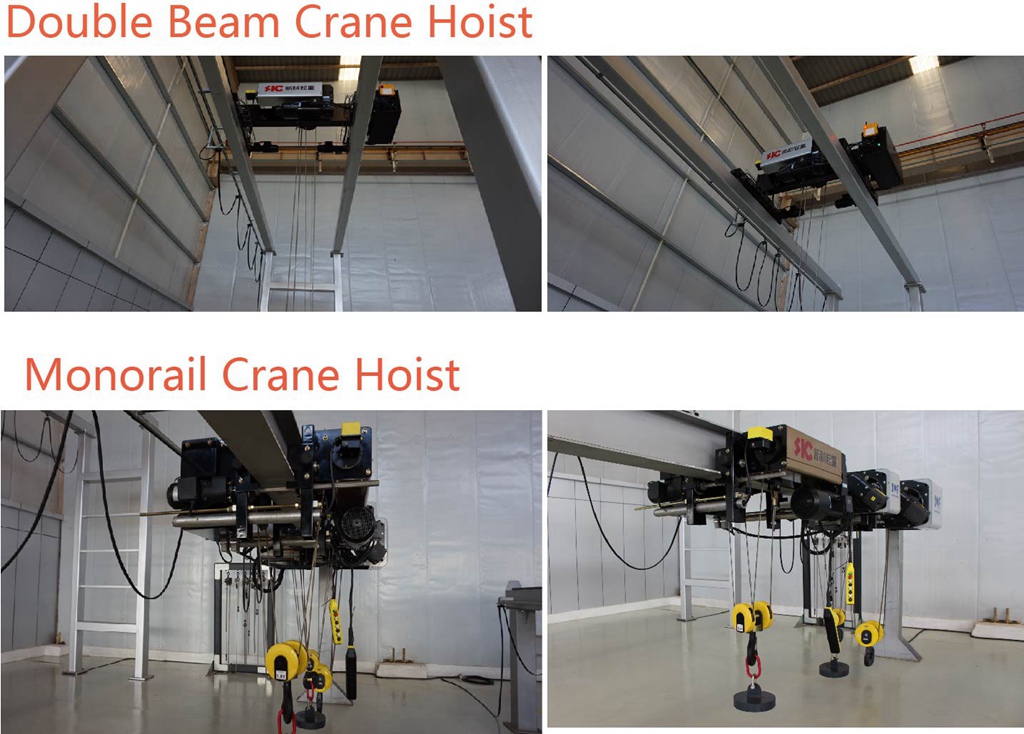

CASE

Explore diverse crane project examples that highlight how our lifting solutions adapt to various industries, environments, and scale demands—from precise installations in tight spaces to heavy-duty operations under extreme conditions—demonstrating reliability and performance across real-world applications.

Automotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a Quote5T LDA Single Beam Overhead Crane for Ethiopian Textile Factory

Boost your lifting efficiency with our 5T Single Girder Bridge Crane — reliable, durable, and built for performance. Perfect for workshops, warehouses, and industrial handling.

Learn More Get a QuoteFAQs

This hoist is designed to operate at FEM 2M and FEM 3M (equivalent to ISO M5 and M6) duty classes, ensuring reliable performance in moderate to heavy-duty industrial applications.

The hoist features a three-stage transmission using involute helical gears housed in aluminum gearboxes. This design reduces headroom while maximizing lift height, letting users cover more workspace within the same plant area.

It includes a deep-groove wire rope guide for tighter, orderly reeling and a high-strength DC disc brake offering up to twice the rated torque for rapid stopping and secure load holding.

Built with high-strength metal structures and an IP54-rated electrical control system, this hoist supports stable operation and straightforward access for inspections and servicing.

Yes. The trolley mechanism is adjustable to fit various rail gauges, and high-end versions allow users to configure the upper lift limit freely, adding flexibility for different workflows.

Its compact structure enables a smaller crane design, which can lower the required height of your plant and supporting structures by over 10%, thereby reducing initial investment while expanding operational coverage.