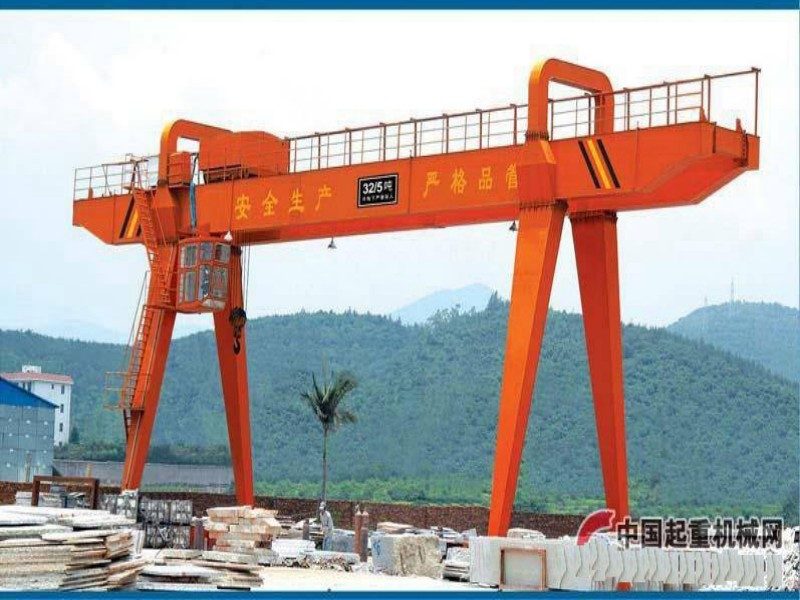

Technical Requirements of Marble Loading Crane:

1. lifting mechanism and operating mechanism running in low speed, in order to improve the prefabrication beam alignment accuracy and reduce the impact on the beam structure.

2. the beam inside the space should be large enough to meet the lifting of prefabricated beams and bridge machine assembly. (Pole machine price)

3. the main steel structure should meet the strength, stiffness, stability under the premise of considering the disassembly and transportation.

4. the use of two crane for lifting prefabricated beams must meet the two loom synchronous operation .

Operation and Maintenance Precautions:

1. the crane operator to be trained, qualified before induction.

2. in strict accordance with the crane operating requirements, operating procedures to operate.

3. The mechanical devices, electrical equipment etc, should have regular inspection and maintenance.

4. found that any problems, Gantry crane should be shut down until the problem is removed.

Features for Key Parts

Structure | Lifting motor, gearbox, drum and limit switch are integrated with compact design to save the user's working space. Apply the modular design to enhance its reliability and meanwhile to reduce effectively the cost and time for maintenance. Hoisting mechanism is designed strictly in the relevant FEM standards. | |

Lifting motor | Small starting current, big torque High acceleration Long service life design High speed, low noise | |

Lifting gearbox | Light weight, corrosion resistance. In the hermetically sealed cabinets, the semi-greasy lubricant makes all the gears adequately lubricated in the designed safety using cycle . Every gear's surface-hardened and precisive-lapped ensure smooth operation Smooth running,low noise Corrosion-resistant, maintenance-free | |

Lifting brake | Our lifting motor equipped with electric-hydraulic drum type. The brake is installed in the end of motor, the motor brake is automatically closed when the motor without power to prevent the loading slipping. The brake clearance is no need to make manual adjustment after the first set(by the brake springs the clearance adjust itself), According to safety regulations, we use the brake which braking torque is not less than 1.8 times the rated motor torque. Moving fast, high reliability Maintenance-free, self-adjustment Dust proof design ,long life | |

Drum | Drum is made of high-quality seamless steel pipe by CNC machining. The drum grooves and rope guide can effectively prevent the rope loosen and mixed. The rope is made of imported wire rope with high-strength tensile strength, safety and long service life | |

Technical parameter for marble gantry crane

Lifting weight | ton | 3~20 | |||||||

Span | m | 12~30 | |||||||

Lifting height | m | 6m 9m | |||||||

Working | Travelling | Ground | m/min | 20 | |||||

parts | speed | Cabin | 20/30/45 | ||||||

Motor | Ground | YSE802-4/0.8*2 | YSE90L-4/1.5*2 | ||||||

Cabin | ZDR100-4/1.5*2 | ZDR112L1-4/2.1*2 | |||||||

Reducer | Ld | ||||||||

Wheel dia. | mm | 270 | |||||||

Electric | Type | CD1 MD1 | |||||||

hoist | Lifting speed | m/min | 8 0.8/8 | ||||||

Travelling speed | 20 | ||||||||

Motor | Lifting | ZD41-4/4.5 ZDS10.4/4.5 | |||||||

Travelling | ZDY12-4/0.4 | ||||||||

Working class | A3 | ||||||||

Steel track recommended | P24 P38 | ||||||||

Power | 380v 50Hz | ||||||||

The crane weight | Ground | kg | 6646/8646 | 7630/9430 | 10163/12163 | 11931/13931 | |||

Cabin | kg | 6996/8996 | 7780/9780 | 10513/12513 | 12281/14281 | ||||

Max. Wheel pressure | KN | 37/42 | 40/46 | 44/50 | 48/54 | ||||

CASE

Discover how our Marble Loading Gantry Crane with varying lifting capacities can enhance your stone handling operations. Engineered for efficiency and safety, this crane is perfect for quarries and stone factories. Learn how it’s transforming marble lifting processes in the industry.

40.5T Rail-Mounted Gantry Crane Installation for Port Logistics Efficiency

The RMG gantry crane designed and manufactured by Sinokocrane has effectively solved the problems for the customers and reduced their operational costs.

Learn More Get a Quote5T Portable Gantry Crane Deployment for Australian Equipment Rental

The portable gantry cranes provided by Sinoko Cranes for the leasing company of Australian customers have significantly increased the number of rentals for the customers and enhanced the revenue of their companies.

Learn More Get a QuoteInstallation of 10T European-Style Gantry Crane for Pakistani Client by Sinoko Cranes

Struggling with slow manual gates? Sinoko's European gantry crane slashed Pakistan customer's downtime by 64%! Transform your access efficiency – contact us!

Learn More Get a QuoteFAQs

A Marble Loading Gantry Crane is a specialized crane designed to lift and transport heavy marble slabs and stones in quarries, factories, and construction sites. It ensures safe and efficient handling of heavy materials with high precision.

Our Marble Loading Gantry Cranes come in various lifting capacities, ranging from 5 tons to 100 tons, depending on your specific requirements. This flexibility makes it suitable for both small-scale and large-scale marble handling operations.

These cranes are primarily used in marble quarries, stone processing factories, and construction sites. They are ideal for lifting and transporting large marble blocks, slabs, and finished stone products.

Key features include high lifting capacity, durable construction, and precise control systems. The crane is designed to handle heavy, fragile materials like marble, ensuring smooth and safe lifting, loading, and unloading operations.

The crane’s robust design and smooth operation reduce downtime and improve safety. By enabling precise and efficient handling of heavy marble materials, it helps reduce labor costs and enhance overall productivity in the stone industry.

Regular maintenance includes checking the lifting mechanism, inspecting the hoist and rails, and lubricating moving parts. Periodic inspections are crucial to ensure optimal performance and avoid potential breakdowns in the heavy-duty lifting operation.