Overview

YC Upper Rotating Crab Electromagnet Overhead Crane mainly employs hung girder to hoist long objects like billets, and is equipped with lifting electromagnet to hoist.

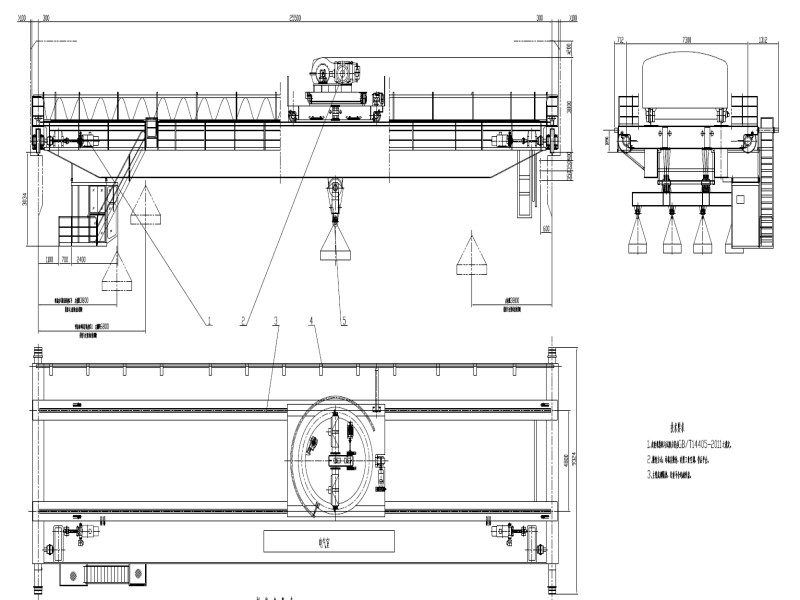

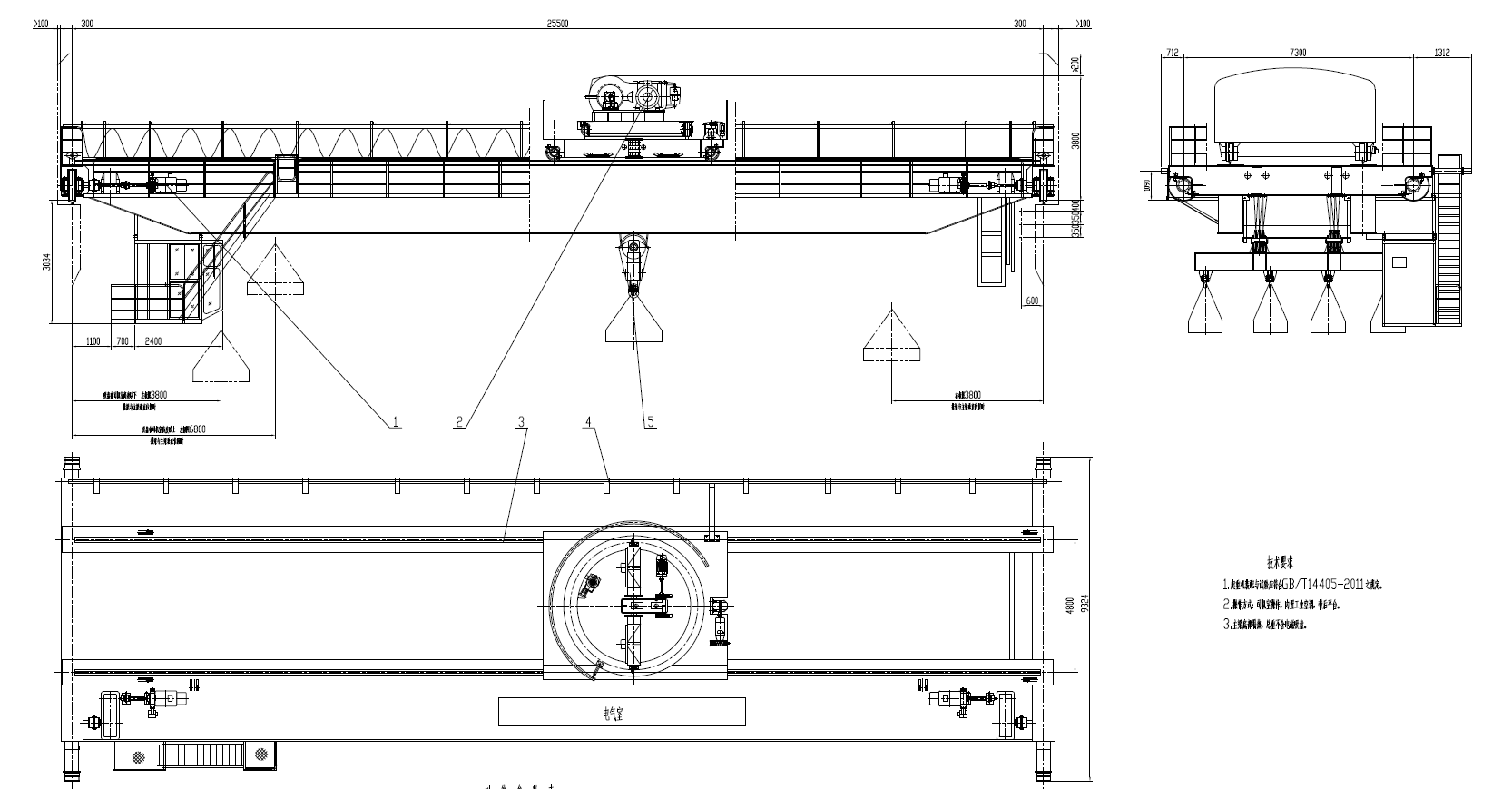

It is composed of box-shaped bridge, crane crab, trolley travelling mechanism, cab and electric control system. It is also equipped with blackout magnetic system.

The girder is a middle-rail box girder, on which laid rails for crane crab to transversely move.

The girder is weld with the box-shaped and girder.

At the middle of the end girder are joints which are fastened with bolts for fragmented transportation of bridges.

The platform is used to place trolley travelling mechanism, electric equipments and for repair. It is furnished with protection railing outside.

The crane crab consists of upper crab and lower crab.

The upper crab is furnished with a circular orbit for rotating, which acts in concert with horizontal wheels to fulfill the purpose of rotating long articles.

Features

1.Lifting material: cast ingot, steel scraps, steel ball, steel billets

2.Wide use in steel plants, melting plant, waste warehouse, billet processing workshop

3.High working efficiency, safe and reliable operation

4.Perfect performance, low maintenance

This crane mainly consists of strong bridge beams, crane travelling mechanism, electric rotating trolley and electric system and magnetic disk system, and could be classified into several working duties, e.g. A5, A6, A7, according to the working frequency and pure working time

It is special magnetic pole is suitable for round coil with different diameters; selection of electromagnet depends on the length of round coil. If the electromagnet is long enough at a time

Upper rotating trolley could save more lifting height for stock purpose, work more smoothly compare to the lower rotating mechanism.

Specification

Capacity | t | 10+10 | 12.5+12.5 | 13.5+13.5 | 15+15 | |

Span | m | 28.5 | 31.5 | 26.5 | ||

Lifting height | m | 16 | 10 | 13 | 12 | |

Working class | A6 | A7 | ||||

Speed | Hoisting | m/min | 11.4 | |||

Rotation | 0.8r/min | |||||

Traveling of crab | 38 | |||||

Traveling of crane | 88 | |||||

Recommended rail | QU80 | |||||

Power supply | 3-Phase 380V 50HZ | |||||

CASE

Explore how our advanced crane systems are applied in real-world industrial settings. From steel mills to material handling yards, our project cases highlight customized solutions that boost efficiency, safety, and performance across diverse lifting applications.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

This crane specializes in lifting and maneuvering long, heavy ferrous materials like billets, ingots, scrap steel, and steel balls. Its rotating trolley enables precise alignment and stacking, making it highly effective in steel mills, melting plants, waste yards, and billet-processing workshops.

The crane features an upper crab-mounted trolley with a circular orbit, allowing the load to rotate horizontally. This flexibility enables better positioning and stacking while conserving lifting height and improving operational smoothness.

Available in double-capacity configurations such as 10+10 t, 12.5+12.5 t, 13.5+13.5 t, and 15+15 t, the span ranges from 26.5 to 31.5 m. Lifting heights vary between 10 and 16 m. The hoisting speed is around 11.4 m/min, rotation speed is 0.8 r/min, crab travel speed is 38 m/min, and crane travel speed reaches 88 m/min. Recommended rails are QU80, and standard power supply is 3-phase 380 V, 50 Hz.

Built for high-duty operations (classes A6–A7), this crane is engineered for long-term reliability and safety. It incorporates robust design elements—like durable bridge beams and electrical systems—to withstand frequent cycles and heavy use.

The crane’s box-shaped bridge girder houses transverse rails for the crab trolley and includes convenient maintenance platforms with protective railings. Its modular design allows easy disassembly and repair, enhancing operational uptime.

All mechanisms—lifting, trolley movement, and rotation—are fully controlled through a central control room. The system typically offers operators choices like cabin, pendant, or wireless remote control to match varied working conditions.