Overview

|

|

Scrap handling electromagnetic overhead crane Load capacity: 5-50t Span: 10.5-31.5 m Lifting height: 6-16m Lifting speed: 7.8-15.5m/min Trolley running speed: 31.3-40.1m/min Crane running speed: 58.5-70.6m/min Work duty: A5-A7 | Scrap handling hydraulic grab overhead crane Load capacity: 5-20t Span: 10.5-31.5m Lifting height: 6-26m Lifting speed: 30.7-39.3m/min Trolley running speed: 31.1-44.6m/min Crane running speed: 76.9-93.6m/min Work duty: A5-A7 |

Features

Scrap Handling Electromagnetic Overhead Crane Features

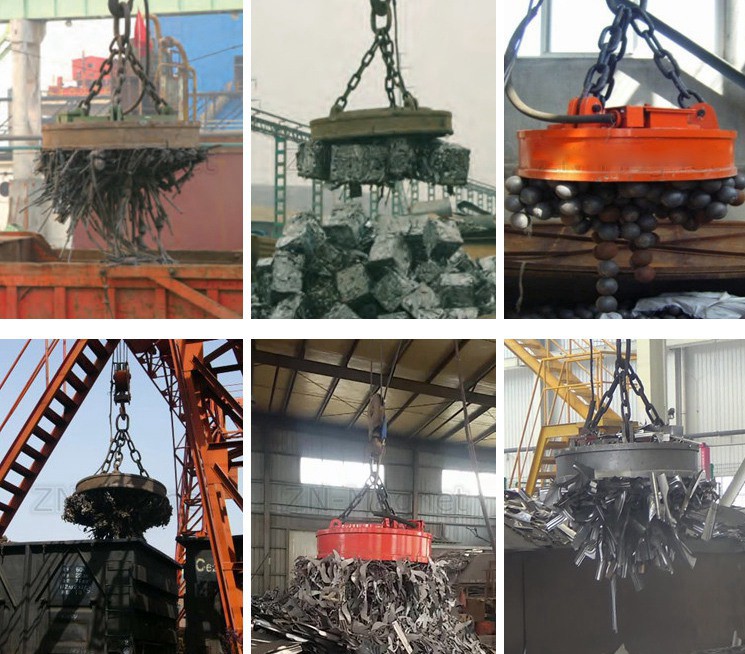

Lifting material: cast ingot, steel scraps, steel ball, steel billets

Wide use in steel plants, melting plant, waste warehouse, billet processing workshop

High working efficiency, safe and reliable operation

Perfect performance, low maintenance

Scrap handling electromagnetic overhead crane mainly consists of strong bridge beams, crane travelling mechanism, electric trolley and electric system and magnetic disk system, and could be classified into several working duties, e.g. A5, A6, A7, according to the working frequency and pure working time

It is special magnetic pole is suitable for round coil with different diameters; selection of electromagnet depends on the length of round coil. If the electromagnet is long enough at a time

Scrap Handling Hydraulic Grab Overhead Crane Features

Scrap handling hydraulic grab overhead crane is the core equipment of the garbage feeding system in the municipal solid waste incineration plant, which is located above the garbage storage pit. Normally there will install 2 sets same specification garbage grab crane for feeding the boiler, mixing, stacking, moving, weighing and stirring, and make sure garbage materials into the boiler evenly.

Specification

QC Model Scrap Handling Electromagnetic EOT Crane | |||||||||||

Lifting Capacity | T | 5t | 10t | 16t | |||||||

Working Duty | A6 | ||||||||||

Span | m | 7.5~31.5m | |||||||||

Max. Lifting Height | m | 16 | 16 | 16 | |||||||

Electromagnetic disk | Type | MW1-6 | MW1-16 | MW1-16 | MW1-16 | ||||||

Suck weight | kg | 4540 | 3330 | 8330 | 14330 | ||||||

Dead weight | 460 | 1670 | 1670 | 1670 | |||||||

Diameter | mm | 776 | 1180 | 1180 | 1180 | ||||||

Lifting Capacity | T | 16/3.2 | 20/5 | 32/5 | |||||||

Electromagnetic disk | Type | MW5-165L6 | MW5-180L | MW5-210L | |||||||

Suck weight | kg | 12500 | 14500 | 21000 | |||||||

Dead weight | 3200 | 4230 | 7000 | ||||||||

Diameter | mm | 1650 | 1800 | 21000 | |||||||

Lifting Capacity | T | 50/10 | |||||||||

Electromagnetic disk | Type | MW5-90L | |||||||||

Suck weight | kg | 4200 | |||||||||

Dead weight | 800 | ||||||||||

Diameter | mm | 900 | |||||||||

Steel track recommended | QU70 | ||||||||||

Power Supply | By your country 3phs voltage | ||||||||||

Hydraulic Grab Specification

| Volume (m3) | Motor 40%ED (kw) | Crane SWL (t) | Grab Weight (kg) |

| 0.5 | 7.3 | 2.5 | 945 |

| 1 | 7.3 | 3 | 1490 |

| 2 | 10 | 5 | 1540 |

| 2.5 | 10 | 6.3 | 2825 |

| 3 | 14.5 | 10 | 3040 |

CASE

Discover how our cranes perform across diverse industries and heavy-duty applications. Explore real project cases to see how we deliver efficient, customized lifting solutions for scrap handling, steel production, and more. Find the right crane system for your operational needs.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

Ideal for heavy-duty scrap handling, this double‑girder overhead crane—equipped with an electromagnetic lifter—is used across metallurgy, mining, machinery, and transportation industries to load and transfer scrap metal into melting processes and storage facilities.

The crane handles loads up to 50 t, spans from 10.5 to 31.5 m, offers lift heights of 6–16 m or up to 26 m with hydraulic grabs, hoisting speeds ranging from 7.8 to 15.5 m/min, trolley speeds of 31.3–40.1 m/min, and bridge travel speeds of 58.5–70.6 m/min.

You can customize this heavy-duty crane with either an electromagnetic disc or a hydraulic grab, depending on your material handling needs—ensuring flexibility between magnet-based and mechanical lifting methods.

This electromagnetic overhead crane is designed to lift diverse ferrous materials such as cast ingots, steel scraps, steel balls, and billets—making it a versatile choice for scrap yards, steel plants, and furnace feeding operations.

Built for continuous heavy-duty operations, this crane supports work cycles from A5 to A7—ensuring reliable performance in high-frequency, demanding industrial environments.

Featuring robust bridge beams, a dependable crane traveling mechanism, an electric trolley and control system, and a magnetic disk assembly with specialized poles, this crane combines high working efficiency, safe and dependable operation, and low-maintenance functionality.